-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

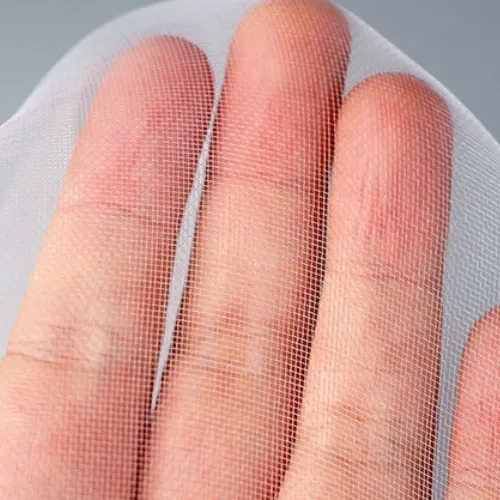

Understanding Steel Sieve Mesh for Optimal Filtration and Material Separation

Understanding Steel Sieve Mesh Applications, Types, and Benefits

Steel sieve mesh, a versatile material widely used across various industries, serves as an essential tool for filtration, separation, and screening processes. Whether in the construction sector, food processing, or mining, the effectiveness of steel sieve mesh is unmatched, making it a fundamental component for those seeking efficient and reliable solutions.

What is Steel Sieve Mesh?

Steel sieve mesh is a woven or welded mesh made from high-quality steel wires. This material is designed to have uniform openings that allow for the efficient passage of liquids and solids. The manufacturing processes utilize different types of steel, including stainless steel, carbon steel, and other alloys, ensuring that the mesh can withstand harsh environments and sustain mechanical stress.

Types of Steel Sieve Mesh

Steel sieve mesh comes in various designs, each tailored for specific applications. The main types include

1. Woven Wire Mesh This type is created by interlacing steel wires in a crisscross pattern. It is known for its flexibility and is available in different mesh sizes and wire diameters. Woven wire mesh is ideal for applications where a fine filtration is necessary, such as in pharmaceutical production or food processing.

2. Welded Wire Mesh Made by welding the intersections of steel wires, this type offers high strength and durability. Welded wire mesh is commonly used in construction and building projects, where structural integrity is paramount. It can also be found in industrial settings where heavy loads are common.

3. Perforated Metal Sheets While not strictly a mesh, perforated sheets play a similar role in filtering and separating materials. These sheets consist of a flat sheet of metal with holes punched through them, allowing for various sizes of materials to pass through. They are often used in architectural applications, as well as in the manufacturing of machinery and equipment.

Applications of Steel Sieve Mesh

steel sieve mesh

The applications of steel sieve mesh are vast and varied, showcasing its adaptability to different sectors

- Construction In construction, steel sieve mesh is utilized in reinforcing concrete, filtering aggregates, and as forms for concrete shaping. Its strength ensures that it can handle significant weight, making it an integral part of structural support.

- Food and Beverage Processing In the food industry, steel sieve mesh is employed for screening and filtering products to ensure purity and safety. It helps in the processing of grains, sugar, dairy, and beverages, ensuring that contaminants are removed before reaching consumers.

- Mining and Mineral Processing Steel sieve mesh is crucial in the mining industry for grading and separating minerals from ores. It enables efficient processing of materials, enhancing productivity and reducing waste.

- Pharmaceuticals In pharmaceutical manufacturing, the accuracy of filtration is vital for producing quality products. Steel sieve mesh ensures that impurities are filtered out effectively, adhering to stringent industry regulations.

Benefits of Using Steel Sieve Mesh

One of the primary benefits of steel sieve mesh is its durability. Unlike other materials, steel can withstand high temperatures, corrosive substances, and physical abrasion. This resilience translates into a longer lifespan, making it a cost-effective choice over time.

Additionally, steel sieve mesh is easy to clean and maintain, which is particularly important in industries where hygiene is critical. Its availability in various shapes and sizes allows for customization to meet specific needs, providing versatility across applications.

Conclusion

In conclusion, steel sieve mesh is a fundamental material that enhances efficiency and productivity across numerous industries. Its unparalleled durability, variety of types, and wide range of applications make it an indispensable tool for businesses aiming to optimize their operations. As industries continue to evolve, the demand for quality steel sieve mesh will undoubtedly remain strong, paving the way for innovative uses and improved technologies in filtration and separation processes.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025