-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable Steel Square Wire Mesh for Versatile Applications and Strong Support

The Versatility and Applications of Steel Square Mesh

Steel square mesh has become a popular choice in various industries due to its strength, durability, and versatility. This form of mesh is typically made from high-quality steel wires that are woven together to create a grid-like pattern of square openings. The robust nature of steel makes it an ideal material for applications that require both safety and performance. In this article, we will explore the characteristics, manufacturing process, and diverse applications of steel square mesh and its importance in modern construction and industry.

Characteristics of Steel Square Mesh

One of the primary features of steel square mesh is its excellent tensile strength. The interwoven structure allows it to bear significant loads without deforming. This is particularly important in construction, where the integrity of materials can directly affect the safety and longevity of a structure. Additionally, steel square mesh is resistant to corrosion, especially when treated with galvanization or other protective coatings, making it suitable for outdoor applications where weather resistance is crucial.

Another noteworthy characteristic is its customizable nature. Steel square mesh is available in various wire diameters and mesh openings, allowing it to be tailored to specific needs. Whether for heavy-duty applications or lightweight uses, the flexibility in size and configuration enables engineers and architects to integrate it seamlessly into their designs.

Manufacturing Process

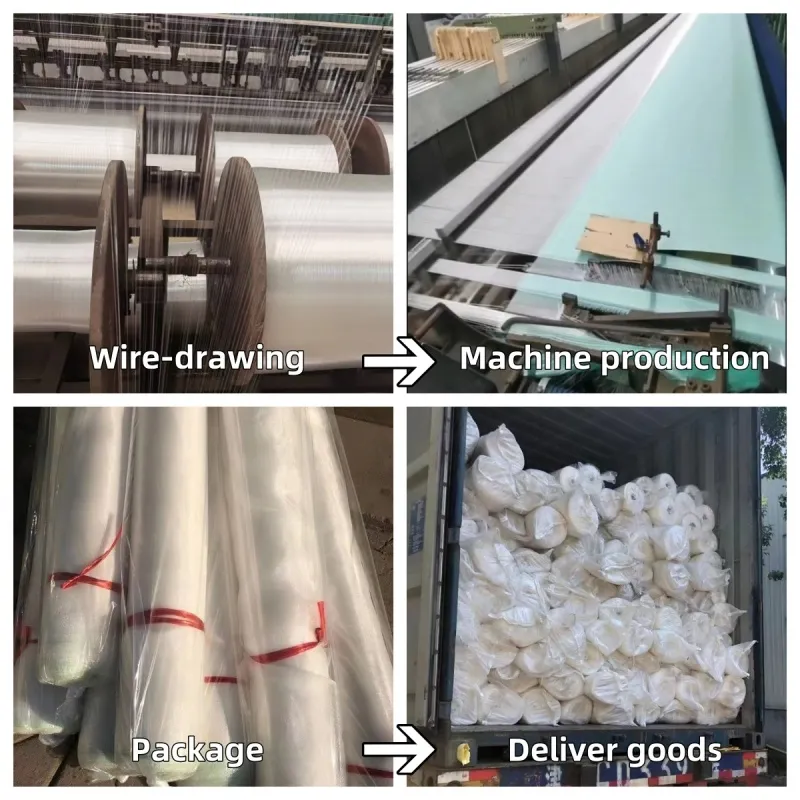

The manufacturing of steel square mesh involves several key steps. It begins with selecting high-quality steel wire, which is then cut to the required lengths. The wires are woven together using automatic weaving machines that create the characteristic square pattern. After weaving, the mesh may undergo additional treatments, such as galvanization, to enhance its resistance to rust and environmental factors.

Quality control is an essential part of the manufacturing process

. Each batch of steel square mesh is tested for strength, durability, and corrosion resistance to ensure that it meets industry standards. This rigorous quality assurance process ensures that the end product can withstand various challenges, from heavy loads to exposure to harsh conditions.Applications of Steel Square Mesh

steel square mesh

Steel square mesh has a wide range of applications across various sectors, reflecting its versatility.

1. Construction Industry In the construction industry, steel square mesh is frequently used as reinforcement in concrete structures. It helps to improve the tensile strength of concrete, preventing cracking and ensuring a longer lifespan. It is also used as a framework for flooring, walls, and ceilings.

2. Fencing and Security Due to its strength and durability, steel square mesh is often utilized in fencing applications. It provides a secure barrier for residential properties, commercial buildings, and industrial sites. The visibility through the mesh allows for surveillance while still providing physical obstruction.

3. Agriculture In agriculture, steel square mesh is employed for creating enclosures for livestock and protection for crops. Its durability ensures that it can withstand the elements and the pressure from animals, marking it as a practical choice for farmers.

4. Manufacturing and Industry Steel square mesh is extensively used in the manufacturing sector for a variety of purposes, such as sieving materials, sorting products, and providing safety measures around machinery. Its sturdy construction makes it ideal for use in machinery guards and safety screens.

5. Art and Design Beyond practical applications, steel square mesh has found its way into artistic endeavors and architectural designs. Designers often use it for creating aesthetically pleasing facades, sculptures, and installations that blend functionality with art.

Conclusion

Steel square mesh is a crucial material that demonstrates the intersection of utility and versatility. Its applications span multiple industries, from construction and agriculture to manufacturing and design. As technology advances, the production techniques for steel square mesh will likely continue to evolve, enhancing its performance and expanding its uses. Whether for structural reinforcement, security, or creative designs, steel square mesh remains a reliable choice for engineers, architects, and designers alike. Its enduring properties ensure that it will continue to play an essential role in modern construction and industry for years to come.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025