-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable Steel Welded Wire for Various Industrial and Construction Applications

The Versatility and Applications of Steel Welded Wire

Steel welded wire, a robust and highly versatile material, has become an integral component in various industries due to its exceptional strength, durability, and adaptability. This wire mesh product, formed by welding together pre-formed wire crossings, is notable for both its structural integrity and its wide range of applications. In this article, we will explore the characteristics, production methods, and diverse uses of steel welded wire, highlighting its significance in modern construction and manufacturing.

One of the key characteristics of steel welded wire is its strength. The welding process creates a uniform mesh structure that offers enhanced load-bearing capabilities compared to traditional wire products. This makes it a preferred choice for reinforcement in concrete structures, such as slabs, walls, and foundations. The integration of steel welded wire into construction projects not only enhances the tensile strength of materials but also improves overall structural stability, reducing the likelihood of cracks and failures over time.

The manufacturing process of steel welded wire involves several steps. First, high-quality steel rods are drawn into wire of specific diameters. Next, these wires are arranged in a grid formation and are then welded at their intersections using resistance welding techniques. This method ensures a consistent bond between wires, resulting in a product that can withstand various types of stress and strain. Additionally, steel welded wire can be galvanized or coated to enhance its resistance to corrosion, further extending its lifespan and making it suitable for outdoor applications.

Steel welded wire finds extensive use in a variety of sectors, including construction, agriculture, and industrial applications. In the construction industry, it is commonly utilized as reinforcement in concrete structures. The mesh is often placed within concrete slabs or walls, providing essential support that allows the concrete to withstand tension and compression forces. Moreover, steel welded wire is instrumental in the creation of precast concrete products, such as walls, beams, and flooring systems.

steel welded wire

In agriculture, steel welded wire is employed to create fencing and enclosures for livestock and crops. Its strength and durability make it an ideal choice for protecting animals from predators and preventing them from escaping. Additionally, the wire mesh is used in the construction of greenhouses, providing support for climbing plants while allowing ample light and airflow.

Steel welded wire is also prevalent in industrial settings, where it is used for making cages, racks, and shelves. Its ability to support heavy loads while maintaining structural integrity makes it a favored option for storage solutions in warehouses and factories. Furthermore, the wire can be manufactured in various sizes and configurations, allowing for tailored solutions that meet specific industrial needs.

Another notable application of steel welded wire is in the realm of safety and security. It serves as a barrier in public spaces, residential areas, and construction sites, providing a reliable method of limiting access and ensuring safety. The sturdy nature of the welded wire mesh makes it difficult to breach, offering an effective deterrent against unauthorized entry or theft.

In conclusion, steel welded wire is a remarkable material characterized by its strength, versatility, and wide-ranging applications. Whether in construction, agriculture, or industrial environments, it plays a vital role in enhancing structural integrity and safety. As industries continue to evolve, the demand for reliable materials like steel welded wire will undoubtedly persist, further solidifying its status as a crucial resource in modern infrastructure and manufacturing. With ongoing advancements in production techniques and protective coatings, steel welded wire is poised to remain a key player in various sectors for years to come.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

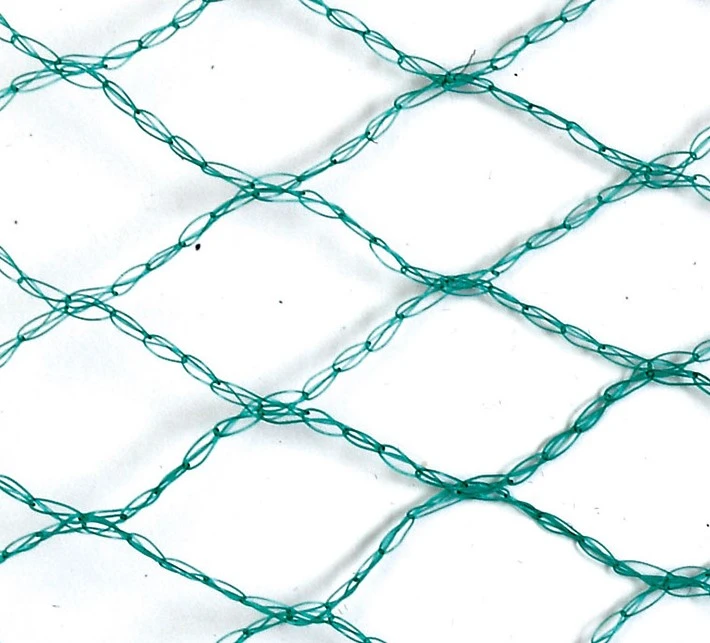

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025