-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 18, 2025 02:08

Back to list

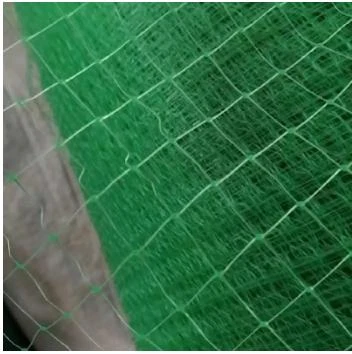

Professional Factory Iron Wire Mesh Cold Plated Electric Welding Mesh

Steel welded wire stands as a paramount product in various industries, serving functions that hinge on its unique material properties and versatility. This resilient product consists of intersecting steel wires that are electrically fused at their junctions, creating a mesh of unparalleled strength and stability. Its broad applications span construction, agriculture, transportation, and beyond, ensuring its recognition as a cornerstone material in project planning and execution.

The expertise embodied in steel welded wire production is extensive. Companies dedicated to this craft invest heavily in state-of-the-art production facilities that employ advanced welding technology to ensure the absolute precision of wire placement and fusion. Industry experts conduct rigorous testing procedures designed to challenge the resilience and tensile strength of welded wire meshes, further elevating their trustworthiness as a primary material in critical applications. Trustworthiness, however, goes beyond product specifications. Leading manufacturers implement environmentally-conscious practices, using recycled materials to produce their wire meshes and adhering to stringent environmental regulations to curtail industrial waste. Such initiatives not only support sustainable development goals but also reassure clients of the ethical considerations intertwined with their purchase decisions. The authority of steel welded wire in various domains is well-established through numerous certifications and endorsements from construction bodies and safety regulators worldwide. Compliance with standards such as ASTM and ISO underscores its reliability and adaptability across different regulations and requirements. In conclusion, steel welded wire emerges as a product that embodies the quintessence of Experience, Expertise, Authoritativeness, and Trustworthiness. Its pervasive presence across industries attests to its unmatched utility and reliability. As technology and industry standards continue to evolve, the role of steel welded wire is likely to expand, driving future innovations in both product applications and environmental stewardship. Through conscious manufacturing practices and continuous enhancement of its robustness and flexibility, steel welded wire stands ready to meet the infrastructure demands of the future.

The expertise embodied in steel welded wire production is extensive. Companies dedicated to this craft invest heavily in state-of-the-art production facilities that employ advanced welding technology to ensure the absolute precision of wire placement and fusion. Industry experts conduct rigorous testing procedures designed to challenge the resilience and tensile strength of welded wire meshes, further elevating their trustworthiness as a primary material in critical applications. Trustworthiness, however, goes beyond product specifications. Leading manufacturers implement environmentally-conscious practices, using recycled materials to produce their wire meshes and adhering to stringent environmental regulations to curtail industrial waste. Such initiatives not only support sustainable development goals but also reassure clients of the ethical considerations intertwined with their purchase decisions. The authority of steel welded wire in various domains is well-established through numerous certifications and endorsements from construction bodies and safety regulators worldwide. Compliance with standards such as ASTM and ISO underscores its reliability and adaptability across different regulations and requirements. In conclusion, steel welded wire emerges as a product that embodies the quintessence of Experience, Expertise, Authoritativeness, and Trustworthiness. Its pervasive presence across industries attests to its unmatched utility and reliability. As technology and industry standards continue to evolve, the role of steel welded wire is likely to expand, driving future innovations in both product applications and environmental stewardship. Through conscious manufacturing practices and continuous enhancement of its robustness and flexibility, steel welded wire stands ready to meet the infrastructure demands of the future.

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025