-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

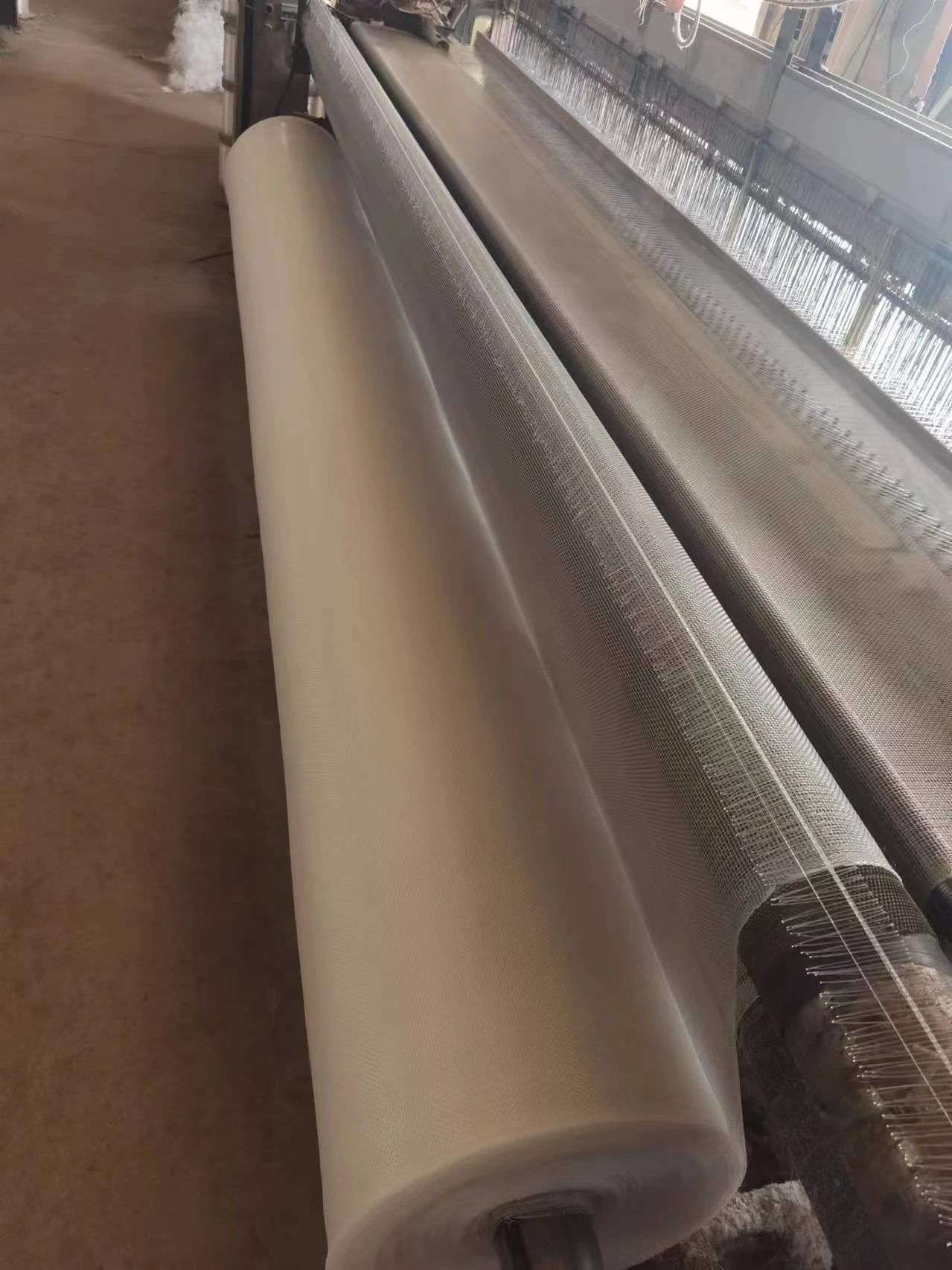

steel wire screen

Steel wire screens are essential components in various industries, offering unparalleled durability and versatility for numerous applications. Made from high-quality steel, these screens are designed to provide exceptional strength and performance, making them ideal for tasks ranging from filtration to industrial separation.

One of the primary uses of steel wire screens is in the construction and mining sectors. Here, they are employed as protective barriers, helping to secure sites and enhance safety during heavy operations. The sturdiness of steel ensures that these screens can withstand harsh environmental conditions, including extreme temperatures and mechanical stress. This resilience not only increases their lifespan but also reduces maintenance costs, making them a cost-effective solution for businesses.

In the realm of filtration, steel wire screens are invaluable. They are extensively used in water treatment facilities and chemical processing plants to separate solids from liquids. The precision of the wire mesh allows for varying degrees of filtration, depending on the gauge and weave of the screen. This adaptability provides industries with the ability to customize their filtration processes, ensuring optimal performance based on specific needs.

Another significant application of steel wire screens is in the agricultural industry. Farmers utilize these screens for sieving soil, grading grains, and protecting crops from pests. The durability of the material ensures that it can endure repeated use in rugged outdoor environments while maintaining its structural integrity. Additionally, steel wire screens can be coated with anti-corrosive materials, further extending their lifespan in agricultural settings where exposure to moisture and chemicals is common.

steel wire screen

In the manufacturing sector, steel wire screens play a crucial role in quality control and production efficiency. They are used in various machines to sort and classify materials during the production process. This functionality not only speeds up operations but also helps maintain high standards of quality, as consistently sized materials are essential for effective manufacturing.

Moreover, the versatility of steel wire screens allows them to be customized for specific applications. With various thicknesses, coatings, and mesh sizes available, businesses can choose the right type of screen to meet their individual requirements. This adaptability underscores the importance of steel wire screens in a wide array of industries, making them a vital component in modern manufacturing and construction processes.

In conclusion, steel wire screens are critical to myriad applications across different industries due to their strength, durability, and adaptability. As technology advances, the development of new wire screen technologies continues to enhance their functionality, ensuring they remain indispensable tools in various fields.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025