Sunshade Net with UV Protection & Custom Sizes—Best Choice?

Sun Shade Cloth Mesh Tarp: The Practical Guide From Factory Floor To Field

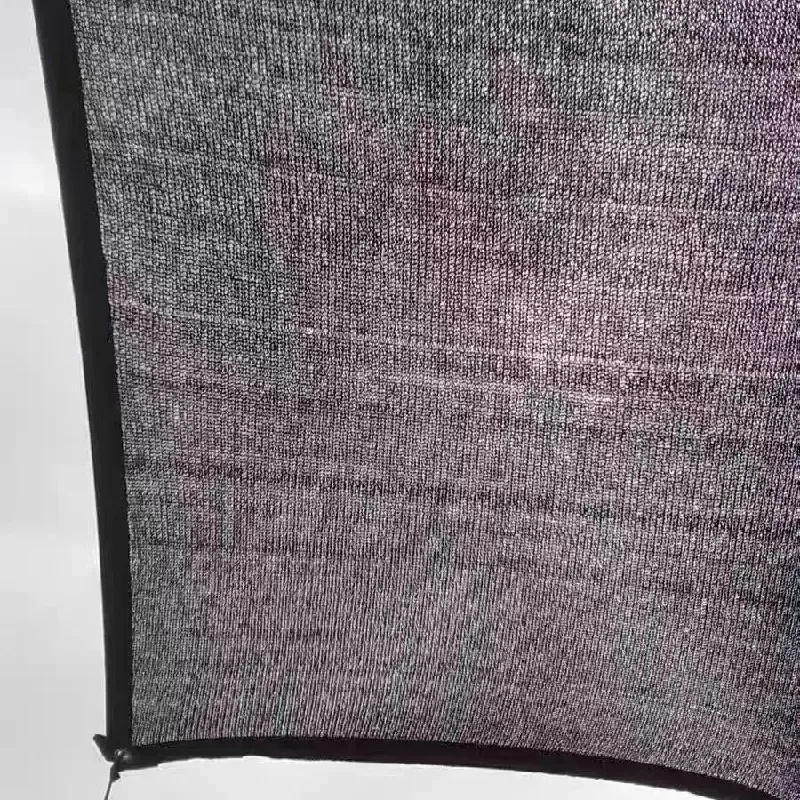

If you’ve been comparing shade fabrics lately, you’ve probably noticed how fast the market is moving. The first thing to know: choosing the right sunshade net isn’t just about percentage numbers on a label—it’s about resin quality, knit density, and UV stabilization that holds up after two summers, not just one. To be honest, the difference shows in the field. This HDPE knitted mesh from China is built for airflow, stretchability, and tear resistance; many customers say it feels “quietly tough,” which I guess is exactly what you want above tomatoes—or a pergola.

What’s trending in 2025

We’re seeing higher GSM options with better UV packages (HALS + carbon black blends), plus reinforced selvedges that reduce fray. Urban growers want lighter colors to tame heat without choking light; commercial farms still lean dark green or black. Surprisingly, event planners are jumping in—temporary shade that doesn’t flap like a sail is a big deal.

Core specs (real-world, not just brochure talk)

| Product | Sun Shade Cloth Mesh Tarp |

| Material | HDPE + UV stabilizers (food-safe pigments; non-toxic) |

| Shade rates | ≈ 50%, 60%, 70%, 80%, 90% (±5% in use) |

| Weight | ≈ 100–320 gsm depending on shade rate |

| Airflow | ~35–70% free area (wind-friendly) |

| Service life | 3–5 years typical; up to 7 in temperate zones (care-dependent) |

How it’s made (quick factory walkthrough)

- Resin: Virgin HDPE pellets blended with UV stabilizers and color masterbatch.

- Knitting: Raschel warp knitting for stretch + tear dissipation; selvedge reinforcement.

- Finishing: Heat-set, trimmed; optional hems, grommets, or buttonholes for ties.

- QA: Roll inspection for pinholes, density, roll weight, and color tolerance (ΔE).

Testing & standards we actually check

- UV aging: ASTM G154 / ISO 4892-3; retention ≥90% tensile after 500 h (lab), ≥80% after 1000 h.

- Tensile/tear: ASTM D5034 (grab) and ASTM D2261 (tear); typical 300–700 N depending gsm.

- Flammability: CA Title 19 small-scale; always verify for public venues.

- Compliance: ISO 9001 plant; RoHS/REACH material statements available.

Use cases? Greenhouses, nurseries, fruit orchards, pergolas, decks, chicken coops, gazebos, balconies—and, yes, temporary event canopies. A sunshade net cuts leaf scorch, tames evapotranspiration, and reduces heat stress on livestock. On patios it’s just… calmer.

Field notes and mini case studies

- Arizona greenhouse, 70% black sunshade net: tomato blossom drop decreased; night temps held better with roll-up sides.

- Spain logistics yard, 60% beige: cooler by ≈6–8°C at noon; less wind lift due to knit porosity.

- Malaysia poultry farm, 80% green: reduced heat stress; farmer reported calmer flocks, fewer water spikes.

Customer feedback: “Edges don’t fray like the bargain roll,” and “grommets actually line up.” Small things, big difference.

Who should you buy from?

| Vendor | Certs | Customization | Lead time | Notes |

|---|---|---|---|---|

| YJ Wire Mesh (Origin: China) | ISO 9001, RoHS/REACH materials | Shade %, color, hem/grommets, roll width | 10–20 days | Balanced price-to-UV package; stable selvedge |

| Generic Importer | Varies | Limited | In stock/uncertain | Watch UV stabilizer content |

| Local Reseller | Often none listed | Cut-to-size | Fast | Convenient; verify knit density |

Customization tips

Pick shade 50–60% for flowers and lettuces; 70–80% for tomatoes and patios; 90% for dog runs or intense sun. Choose lighter colors if glare bothers you. Ask for edge hemming + brass grommets every 2 ft. A sunshade net with UV ≥2% by resin weight generally survives harsh summers better.

Bottom line: a well-made sunshade net is equipment, not a disposable accessory. Buy once, install cleanly, and it earns its keep season after season.

References

- ASTM G154: Standard Practice for UV Exposure of Nonmetallic Materials. https://www.astm.org/g0154

- ASTM D5034: Breaking Strength and Elongation of Textile Fabrics. https://www.astm.org/d5034

- ISO 4892-3: Plastics — Methods of exposure to laboratory light sources. https://www.iso.org/standard/61000.html

- FAO Greenhouse Crop Production guidance on shading. https://www.fao.org/

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025