-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 06, 2025 01:36

Back to list

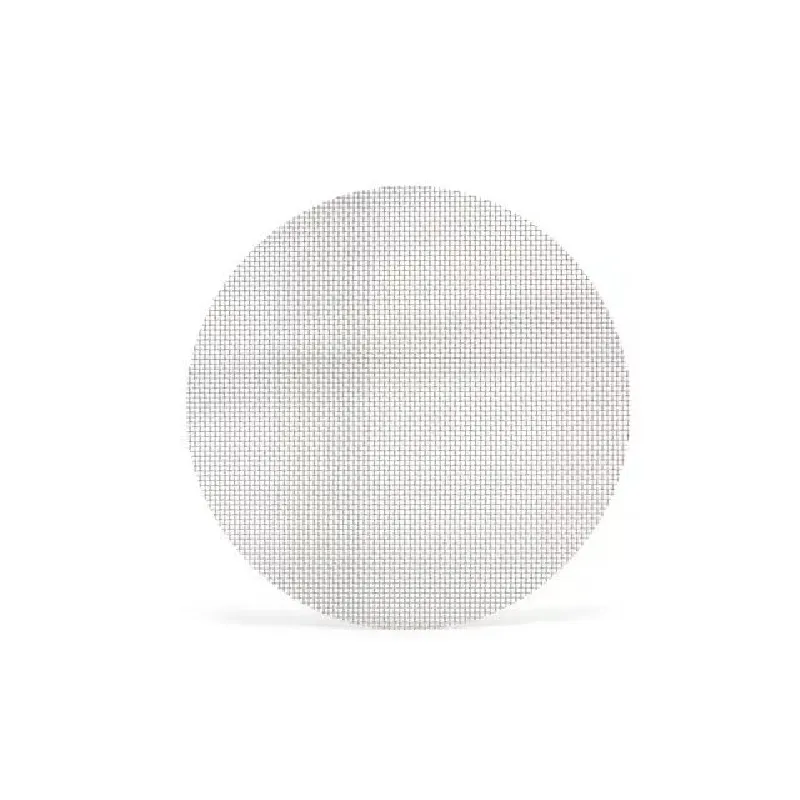

thick gauge wire mesh

Navigating the intricate world of high-quality materials, thick gauge wire mesh stands out as a pivotal component across various industries. Its versatility and resilience make it a preferred choice for applications demanding durability and precision. Drawing from years of expertise in material science and engineering, this article delves into the myriad advantages of thick gauge wire mesh, shedding light on its unique properties that set it apart in demanding environments.

Authoritativeness in this domain is underscored by compliance with industry standards and certifications. Thick gauge wire mesh products that adhere to rigorous ASTM, ISO, or DIN standards guarantee reliability and safety, critical factors in their application in structural support and safety barriers. Furthermore, expert installations backed by a certified professional not only enhance the effectiveness of the mesh but also mitigate the risk of failure, ensuring long-term stability and security in critical infrastructure. Trustworthiness is solidified through field-tested applications and feedback from industry leaders who vouch for the product's efficacy. Case studies often illustrate the successful deployment of thick gauge wire mesh in challenging scenarios; for instance, in earthquake-prone regions, its use in reinforcing concrete structures has been pivotal in enhancing seismic resilience. Similarly, in mining operations, its application in screening and sifting processes has proven essential in maximizing efficiency and throughput. In conclusion, thick gauge wire mesh is not merely a component; it is an essential element that combines durability, flexibility, and reliability, catering to the demands of complex industrial landscapes. The intricate knowledge of its production, material properties, and industry standards positions it as a cornerstone material that industry professionals rely on to ensure safety, efficiency, and longevity in their operations. As the landscape of industrial material applications continues to evolve, thick gauge wire mesh remains a testament to the synergy between engineering expertise and practical experience, promising continued excellence in future applications.

Authoritativeness in this domain is underscored by compliance with industry standards and certifications. Thick gauge wire mesh products that adhere to rigorous ASTM, ISO, or DIN standards guarantee reliability and safety, critical factors in their application in structural support and safety barriers. Furthermore, expert installations backed by a certified professional not only enhance the effectiveness of the mesh but also mitigate the risk of failure, ensuring long-term stability and security in critical infrastructure. Trustworthiness is solidified through field-tested applications and feedback from industry leaders who vouch for the product's efficacy. Case studies often illustrate the successful deployment of thick gauge wire mesh in challenging scenarios; for instance, in earthquake-prone regions, its use in reinforcing concrete structures has been pivotal in enhancing seismic resilience. Similarly, in mining operations, its application in screening and sifting processes has proven essential in maximizing efficiency and throughput. In conclusion, thick gauge wire mesh is not merely a component; it is an essential element that combines durability, flexibility, and reliability, catering to the demands of complex industrial landscapes. The intricate knowledge of its production, material properties, and industry standards positions it as a cornerstone material that industry professionals rely on to ensure safety, efficiency, and longevity in their operations. As the landscape of industrial material applications continues to evolve, thick gauge wire mesh remains a testament to the synergy between engineering expertise and practical experience, promising continued excellence in future applications.

Next:

Latest news

-

Optimal Fish Rearing with Premium Breeding Net SolutionsNewsJul.18,2025

-

High-Strength Construction Wire Mesh for Structural Integrity and SafetyNewsJul.18,2025

-

Ensuring Protection and Efficiency in Construction and StorageNewsJul.18,2025

-

Enhancing Crop Protection with High-Quality Agriculture Shade NetsNewsJul.18,2025

-

Dunnage Bags and Shipping Plastic Bags for Secure TransportNewsJul.18,2025

-

Comprehensive Protection for Construction and InfrastructureNewsJul.18,2025