Welded Wire for Strong, Rust-Proof Fencing—Why Choose Us?

welded wire,3x3 wire mesh,welding fence wire is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of wire mesh products. This article explores how Anping County Yongji Metal Products Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- welded wire,3x3 wire mesh,welding fence wire Overview

- Benefits & Use Cases of welded wire,3x3 wire mesh,welding fence wire in Manufacturing of wire mesh products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on welded wire,3x3 wire mesh,welding fence wire from Anping County Yongji Metal Products Co., Ltd.

welded wire,3x3 wire mesh,welding fence wire Overview

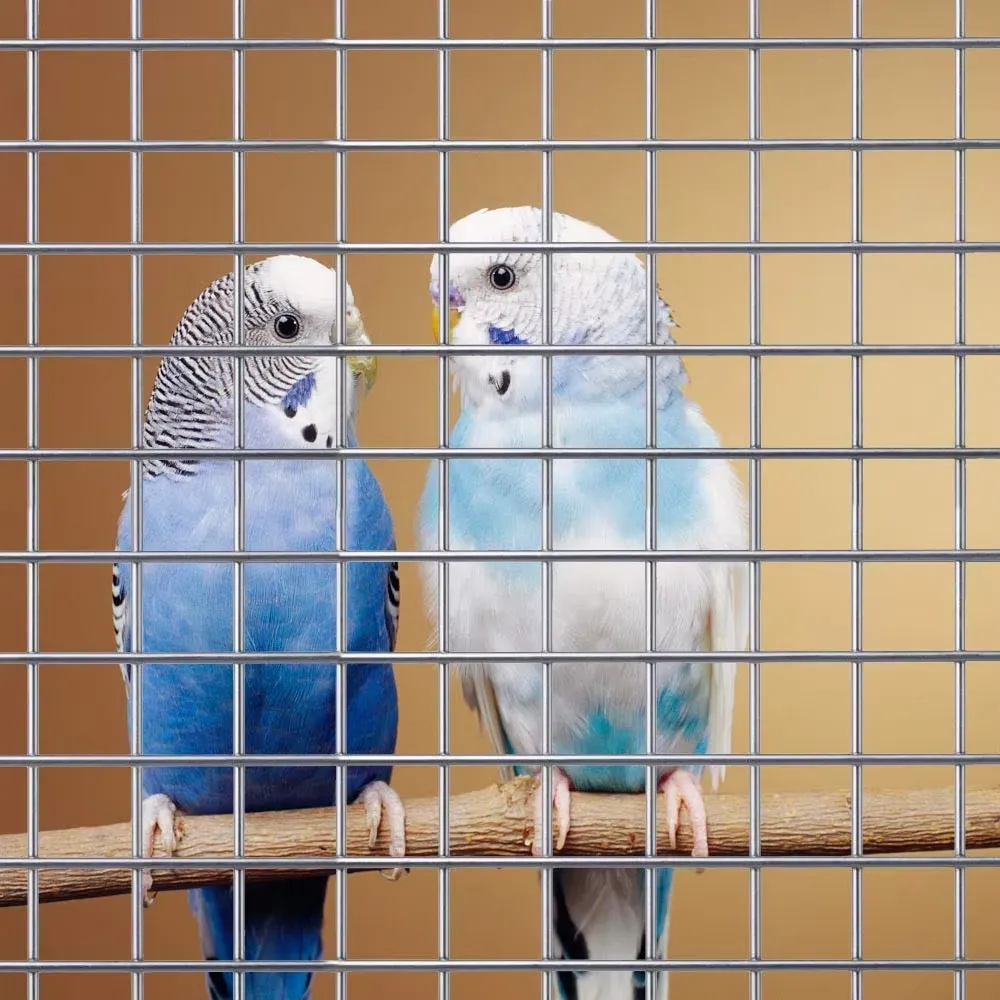

Welded wire mesh is a precision-joined steel grid in which longitudinal and cross wires are fused at their intersections by electric resistance welding. For B2B buyers in fabricated metal products, 3x3 wire mesh refers to a 3 in × 3 in (about 76.2 × 76.2 mm) aperture commonly specified for security fencing, animal enclosures, and equipment guarding. Depending on performance needs, the mesh can be produced from low-carbon steel or stainless wire, and finished as plain steel, electro-galvanized (often called cold-plated), hot-dip galvanized, or PVC/powder coated. Typical wire diameters range from 2.0–6.0 mm, with sheet/roll formats and panel sizes customized to project drawings.

Anping County Yongji Metal Products Co., Ltd. manufactures welding fence wire and welded wire mesh with tight dimensional tolerances, consistent weld shear strength, and flatness that streamlines downstream fabrication. Standard specifications can include zinc coating weights suited for indoor to harsh outdoor exposure and edge trims that reduce snagging during installation. For OEMs and contractors, Yongji’s ability to supply 3x3 wire mesh in bulk rolls or pre-cut panels helps minimize cutting waste, shorten assembly time, and ensure repeatable quality from lot to lot.

Benefits & Use Cases of welded wire,3x3 wire mesh,welding fence wire in Manufacturing of wire mesh products

Across Manufacturing of wire mesh products, welded wire is a versatile input for perimeter fencing, site hoarding, machine guards, warehouse partitions, animal cages, ventilation screens, and protective barriers around telecom and utility assets. 3x3 wire mesh strikes a balance between visibility and deterrence, making it a go-to choice for fencing lines and modular enclosures. When produced with heavier gauges and high-quality galvanizing, welding fence wire delivers strong impact resistance and long service life in logistics parks, industrial campuses, and agricultural environments.

Anping County Yongji Metal Products Co., Ltd. offers competitive advantages that matter to B2B decision-makers: stable raw material sourcing, consistent weld quality, and customization options such as aperture size, wire gauge, edge styles, and coating systems. Flat panels with uniform apertures reduce rework, while precision straightening and trimming accelerate jig setup in fabrication shops. For distributors, Yongji can supply branded packaging, palletized loads, and documentation support to simplify import, warehousing, and resale. These capabilities allow customers to integrate welded wire, 3x3 wire mesh, and welding fence wire into finished goods with predictable throughput and fewer quality holds.

Cost, Maintenance & User Experience

Total cost of ownership for welded wire solutions is driven by material grade, coating system, installation labor, and lifespan in the target environment. While heavier wire gauges and higher zinc weights increase upfront cost, they significantly reduce replacement cycles and maintenance—often delivering superior ROI over multi-year horizons. For outdoor fencing, upgrading to hot-dip galvanized or powder-coated finishes can lower corrosion-related service calls, while pre-cut 3x3 wire mesh panels reduce on-site fabrication time and scrap.

B2B users typically report smoother installation when panels arrive flat, square, and within tolerance, with consistent weld integrity that resists deformation during tensioning. Maintenance is straightforward: periodic rinsing to remove salts and debris, inspection of tie points and posts, and timely touch-up of coatings where mechanical abrasion occurs. Anping County Yongji Metal Products Co., Ltd. supports a low-variance supply chain with clear specifications, batch traceability when required, and packaging that protects edges and coatings during transit—reducing hidden costs from damage, rework, and schedule delays.

Sustainability & Market Trends in manufacturing

Demand for welded wire and welding fence wire is rising alongside infrastructure expansion, logistics growth, and heightened safety requirements in manufacturing environments. Buyers increasingly prioritize longer service life, safer workplaces, and materials that align with corporate sustainability goals. Steel wire mesh supports circularity through recyclability, and durable coatings extend service life, lowering the environmental footprint associated with frequent replacement. In parallel, tightening standards around worker safety and perimeter security are reinforcing the use of consistent, testable products such as 3x3 wire mesh in industrial and commercial settings.

Anping County Yongji Metal Products Co., Ltd. takes a forward-thinking approach by emphasizing material efficiency, finish selection for extended durability, and packaging that reduces waste while improving handling. The company can work with buyers on documentation needs and specification alignment, helping projects meet regional regulations and project requirements. For B2B decision-makers, partnering with a manufacturer that prioritizes durability and responsible sourcing supports both compliance and long-term value creation in the supply chain.

Conclusion on welded wire,3x3 wire mesh,welding fence wire from Anping County Yongji Metal Products Co., Ltd.

Welded wire, 3x3 wire mesh, and welding fence wire are proven, cost-effective building blocks across fabricated metal products and the Manufacturing of wire mesh products. With precise welding, optimized coatings, and dependable flatness, Anping County Yongji Metal Products Co., Ltd. helps B2B buyers achieve consistent quality, faster installations, and longer service life.

Contact us: email: admin@yjwiremesh.com

Visit our website: https://www.yjwiremesh.com

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025