Welded Wire Mesh | Galvanized & Stainless, Custom Panels

welded wire mesh is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal mesh and products. This article explores how Anping County Yongji Metal Products Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- welded wire mesh Overview

- Benefits & Use Cases of welded wire mesh in Manufacturing of metal mesh and products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on welded wire mesh from Anping County Yongji Metal Products Co., Ltd.

welded wire mesh Overview

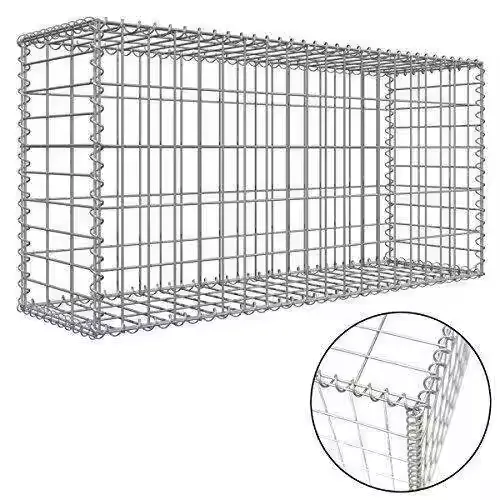

Welded wire mesh is an engineered grid made by resistance-welding intersecting steel wires to create rigid, dimensionally stable panels or rolls. In the Fabricated metal products sector, it underpins solutions ranging from gabion structures and architectural cladding to machine guarding and industrial partitioning. For demanding civil and industrial projects, welded wire mesh delivers predictable strength, uniform apertures, and fast installation—key requirements for B2B decision makers seeking reliability and long service life.

- Typical specifications include low-carbon steel (e.g., Q195/Q235) or stainless 304/316; wire diameter options from 3.0–6.0 mm; common apertures 50×50, 75×75, 100×100 mm; coatings such as hot-dip galvanizing, zinc-aluminum (Galfan), or PVC. Panels can be sized for rapid site assembly, including modular gabion boxes like 2×1×1 m.

- Technical benefits include consistent weld shear strength, tight dimensional tolerances, and excellent flatness. Hot-dipped galvanized welded wire mesh provides robust corrosion resistance for outdoor and marine-adjacent applications.

- Anping County Yongji Metal Products Co., Ltd. manufactures welded mesh products with automated welding lines and rigorous QC, supporting custom apertures, wire diameters, and coatings to match engineering specifications and project standards.

Benefits & Use Cases of welded wire mesh in Manufacturing of metal mesh and products

Across Manufacturing of metal mesh and products, welded wire mesh is chosen for structural gabions, slope stabilization, channel lining, retaining walls, site fencing, infill panels, cages, shelving, and machinery safety guards. Compared with woven alternatives, welded grids deliver superior panel flatness, precise apertures, and higher dimensional stability—improving build accuracy and reducing rework. For civil works, welded gabion boxes enable clean architectural lines and predictable mechanical performance, ideal for visible infrastructure and landscape architecture.

- Applications: retaining walls and revetments, bridge abutment protection, noise barrier foundations, plant and warehouse partitions, and OEM fabrications requiring rigid, weld-ready mesh components.

- Competitive advantages: fast, modular installation; consistent aperture geometry for even fill in gabions; strong corrosion protection via hot-dipped galvanizing; and compatibility with cut/bend/weld fabrication workflows.

- Anping County Yongji Metal Products Co., Ltd. brings deep category expertise—from design assistance and sampling to volume supply—featuring products like the 2×1×1 m hot-dipped galvanized welded gabion mesh, aligned to international project needs and contractor preferences.

Cost, Maintenance & User Experience

Total cost of ownership for welded wire mesh favors B2B buyers seeking predictable budgets and lifecycle value. Rigid, uniform panels accelerate installation and minimize on-site adjustments, translating to labor efficiencies and fewer delays. Hot-dipped galvanized coatings extend service life in outdoor environments, lowering maintenance frequency and replacement cycles. Over multi-year horizons, these gains contribute to a compelling ROI—especially in civil, utilities, and industrial warehousing projects where downtime and rework carry high indirect costs.

- Fabricated metal products customers report positive user experience with consistent panel flatness and tight tolerances that support faster fit-up for frames, posts, and gabion assembly. The result is smoother project sequencing and more accurate bill-of-materials planning.

- Anping County Yongji Metal Products Co., Ltd. supports cost control with optimized packaging, reliable lead times, and options for custom specifications that reduce downstream processing, helping OEMs and contractors keep projects on schedule and within budget.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping procurement in metal mesh manufacturing. Steel’s recyclability and the long service life of hot-dip galvanized welded wire mesh help reduce material turnover and waste. Many buyers now prioritize durable, modular solutions that lower lifetime environmental impact by minimizing replacements and site interventions. Market trends also point to growth in prefabricated components, digital QC, and corrosion-resistant coatings that perform across diverse climates and infrastructures.

- Regulatory momentum toward resilient infrastructure and responsible sourcing encourages products that deliver both durability and circularity. Welded wire mesh aligns well by combining strength, recyclability, and design flexibility.

- Anping County Yongji Metal Products Co., Ltd. positions itself as a forward-thinking partner, offering coating and material options that support longevity and reduced maintenance, and adopting manufacturing practices that prioritize quality consistency and resource efficiency to meet evolving buyer expectations.

Conclusion on welded wire mesh from Anping County Yongji Metal Products Co., Ltd.

Welded wire mesh delivers the strength, precision, and longevity B2B decision makers expect in manufacturing, Fabricated metal products, and the broader Manufacturing of metal mesh and products. With proven capabilities in welded gabion boxes and industrial panels, Anping County Yongji Metal Products Co., Ltd. is a reliable partner for projects that demand durability, speed, and value. Contact us: email: admin@yjwiremesh.com — Visit our website: https://www.yjwiremesh.com

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025