-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

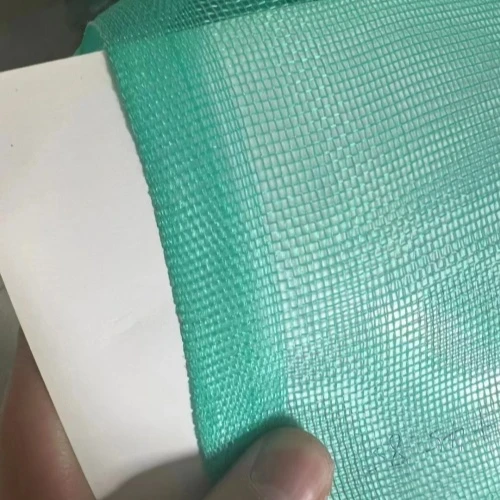

Exploring the Benefits and Applications of Welded Wire Screens in Modern Industries

The Benefits and Applications of Welded Screens

Welded screens have become increasingly popular in various industries due to their strength, durability, and versatility. Composed of wire mesh that is mechanically welded at the intersection points, these screens offer a robust solution for many applications, ranging from construction to agriculture.

One of the key advantages of welded screens is their structural integrity. The welding process creates a uniform and consistent mesh pattern, which enhances the overall strength of the screen. Unlike traditional woven wire screens, which may be prone to loosening or fraying over time, welded screens maintain their form and functionality, making them ideal for high-stress environments. They are commonly used in fencing, creating secure enclosures for livestock, and safeguarding construction sites.

In the construction industry, welded screens are often utilized in concrete reinforcement. When embedded within concrete structures, these screens provide additional support and prevent cracking and shifting. This is particularly beneficial in large-scale projects such as bridges, highways, and buildings, where stability is paramount. The use of welded screens helps to extend the lifespan of concrete structures and reduce maintenance costs over time.

welded screen

Agricultural applications also benefit greatly from welded screens

. Farmers use them for various purposes, including the creation of pest control barriers and protective enclosures for crops. The fine mesh allows air and light to permeate while keeping unwanted animals and insects at bay. This enhances crop yield and quality, making welded screens an invaluable investment for modern agriculture.In addition to construction and agriculture, welded screens are widely used in industrial settings. They are employed in machinery guardrails, security screens, and filtration systems. Their ability to withstand harsh environments and heavy usage makes them suitable for factories, warehouses, and distribution centers. Moreover, their open design facilitates visibility and airflow, which is crucial in many industrial applications.

Furthermore, welded screens are customizable. Available in various materials, such as stainless steel, galvanized steel, and vinyl-coated options, they can be tailored to meet specific requirements. This versatility allows businesses to find the perfect fit for their needs, ensuring optimal performance in all applications.

In conclusion, welded screens offer a myriad of benefits across different industries. Their strength, durability, and adaptability make them an excellent choice for construction, agriculture, and industrial use. As industries continue to evolve, the demand for such reliable solutions will only grow, positioning welded screens as a cornerstone in modern construction and manufacturing practices.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025