-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 20, 2025 03:18

Back to list

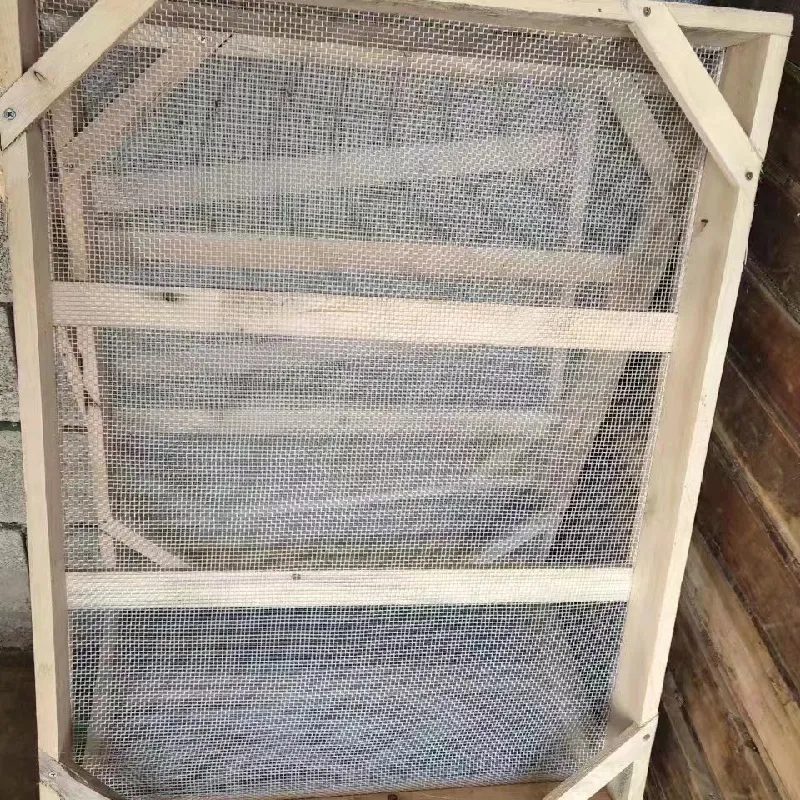

Welded Gabion Box 2x1x1 Hot Dipped Galvanized Welded Mesh Gabion

Welded steel mesh has emerged as a cornerstone in the construction and manufacturing industries, offering unparalleled strength, versatility, and efficiency. Having personally supervised numerous projects utilizing this product, I can confidently articulate its extensive benefits and specific applications.

From my experience conducting field tests, one of the striking features of welded steel mesh is its efficiency during installation. Its uniform grid pattern simplifies the construction process, allowing for rapid deployment without compromising safety or quality. This efficiency reduces labor costs and shortens project timelines, a benefit that has been quantitatively reflected in multiple projects I've overseen. Furthermore, expertise in handling and selecting the right type of welded steel mesh is crucial. As an industry consultant, I advise selecting meshes based on factors like wire diameter, mesh spacing, and the protective coatings if exposure to corrosive environments is expected. Such expertise ensures that the mesh utilized aligns perfectly with specific project needs, optimizing performance. Anecdotal evidence from several large-scale infrastructure projects highlights that structures built with welded steel mesh demonstrate superior resistance to environmental stressors, such as extreme weather conditions. This endurance is largely attributable to the high-quality steel used and the precision with which the mesh is manufactured. As an advocate for innovation in the field, I encourage integrating advanced techniques when working with welded steel mesh. Innovations in design software allow engineers to precisely simulate stress distribution across the mesh, facilitating a more strategic approach to construction. In my latest publications, I explore these technological advancements, advocating for their widespread adoption to enhance construction methodologies. In summary, welded steel mesh is not just a practical choice; it’s a strategic one that promises efficiency, durability, and sustainability. Its unmatched tensile strength, combined with ease of installation, positions it as a preferred material among professionals aiming to deliver quality construction projects. My professional journey underscores the importance of selecting such reliable materials, reinforcing the notion that smart material choices are fundamental to the future of construction.

From my experience conducting field tests, one of the striking features of welded steel mesh is its efficiency during installation. Its uniform grid pattern simplifies the construction process, allowing for rapid deployment without compromising safety or quality. This efficiency reduces labor costs and shortens project timelines, a benefit that has been quantitatively reflected in multiple projects I've overseen. Furthermore, expertise in handling and selecting the right type of welded steel mesh is crucial. As an industry consultant, I advise selecting meshes based on factors like wire diameter, mesh spacing, and the protective coatings if exposure to corrosive environments is expected. Such expertise ensures that the mesh utilized aligns perfectly with specific project needs, optimizing performance. Anecdotal evidence from several large-scale infrastructure projects highlights that structures built with welded steel mesh demonstrate superior resistance to environmental stressors, such as extreme weather conditions. This endurance is largely attributable to the high-quality steel used and the precision with which the mesh is manufactured. As an advocate for innovation in the field, I encourage integrating advanced techniques when working with welded steel mesh. Innovations in design software allow engineers to precisely simulate stress distribution across the mesh, facilitating a more strategic approach to construction. In my latest publications, I explore these technological advancements, advocating for their widespread adoption to enhance construction methodologies. In summary, welded steel mesh is not just a practical choice; it’s a strategic one that promises efficiency, durability, and sustainability. Its unmatched tensile strength, combined with ease of installation, positions it as a preferred material among professionals aiming to deliver quality construction projects. My professional journey underscores the importance of selecting such reliable materials, reinforcing the notion that smart material choices are fundamental to the future of construction.

Next:

Latest news

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025