-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Welded Steel Wire Fabric Applications and Benefits in Construction Industry

The Significance of Welded Steel Wire Fabric in Modern Construction

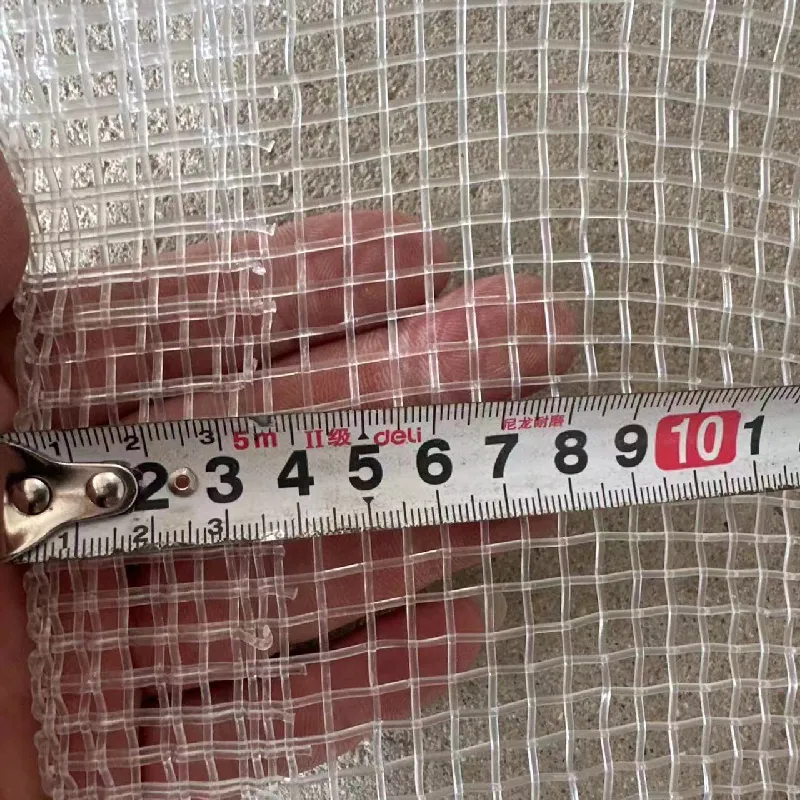

Welded steel wire fabric (WSWF) is an essential component in the contemporary construction industry, playing a pivotal role in reinforced concrete applications. Comprising a series of longitudinal and transverse steel wires that are welded together at their intersections, this innovative material enhances the structural integrity of various constructions, from residential buildings to large-scale infrastructure projects.

One of the primary advantages of welded steel wire fabric is its ability to provide uniform strength across various surfaces. Unlike traditional rebar, which can be cumbersome to install and requires significant labor, WSWF offers a grid of steel that can be easily laid out and incorporated into concrete pour applications. This uniform distribution of steel contributes to improved load-bearing capacity and reduces the risk of cracking and deformation in the concrete. The welded intersections ensure that the wires maintain their positions during the pouring process, further enhancing the effectiveness of the reinforcement.

Moreover, WSWF is highly versatile and can be manufactured to suit a wide variety of construction needs. Available in different sizes, shapes, and grades, welded wire fabric can be easily customized to meet specific design requirements. This adaptability makes it ideal for use in diverse applications, including slabs on grade, precast concrete elements, sidewalks, and retaining walls. Additionally, it can be used in both residential and commercial projects, demonstrating its widespread acceptance in the industry.

welded steel wire fabric

The installation of welded steel wire fabric is not only efficient but also cost-effective

. By simplifying the reinforcement process, it significantly reduces labor costs and construction time. Projects can benefit from accelerated timelines, allowing for quicker occupancy and reduced overhead costs for contractors. Furthermore, the material’s durability and resistance to corrosion make it a long-lasting choice, ultimately leading to lower maintenance expenses over the lifespan of the structures.In addition to its practical advantages, the use of welded steel wire fabric aligns with sustainable construction practices. By maximizing the strength and efficiency of materials, WSWF contributes to more resource-effective designs. Reduced material wastage and lower impacts on the environment are additional benefits linked to the use of this modern reinforcement solution.

Despite its numerous advantages, it is crucial to ensure that WSWF is correctly designed and installed. Engineers must consider factors such as load requirements, environmental conditions, and the specific characteristics of the concrete used. Proper spacing and positioning of the welded wire fabric within the concrete matrix are also essential to ensure optimal performance.

In conclusion, welded steel wire fabric serves as a vital element in modern construction, offering myriad benefits that enhance the efficiency, strength, and sustainability of structures. Its versatility, ease of installation, and cost-effectiveness make it a go-to choice for builders across various sectors. As the construction industry continues to evolve, the integration of advanced materials like WSWF will play a key role in achieving more resilient and sustainable built environments. With ongoing innovations and improvements, the future of welded steel wire fabric looks promising, positioning it firmly within the forefront of construction technology.

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025