-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

welded wire fabric

Understanding Welded Wire Fabric Applications, Benefits, and Considerations

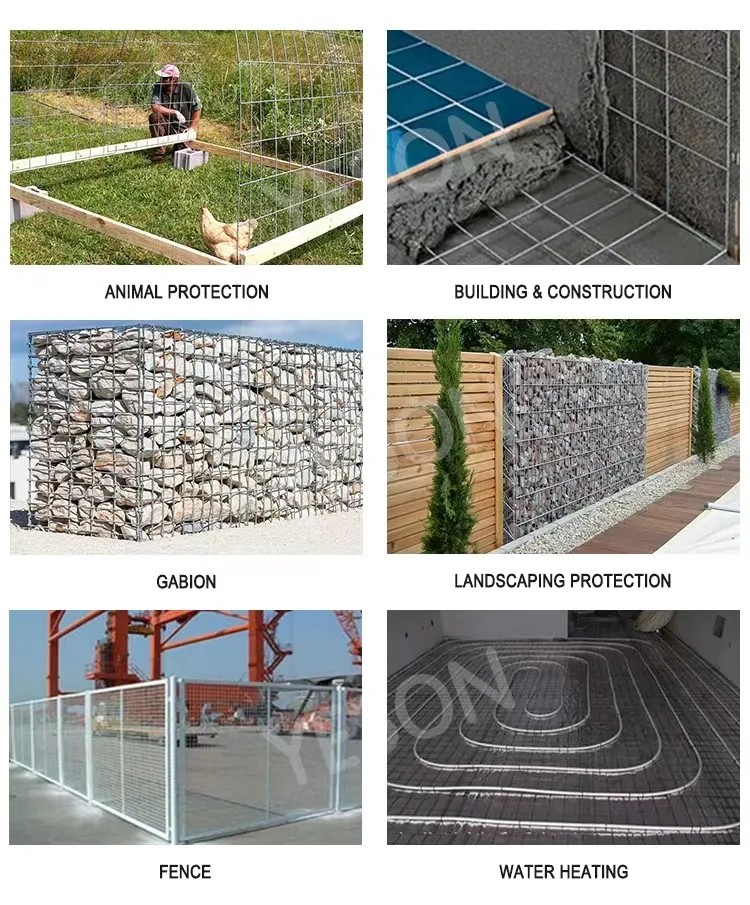

Welded wire fabric (WWF), often referred to as welded wire mesh, is a widely utilized construction material known for its strength, durability, and versatility. Comprised of a grid of wires that are welded together at intersections, this fabric is typically made from steel and applies to various construction and industrial uses. In this article, we will explore the applications, benefits, and important considerations when working with welded wire fabric.

Applications of Welded Wire Fabric

Welded wire fabric is used in numerous applications across different industries. One of the most common uses is in concrete reinforcement. WWF is embedded within concrete to enhance its tensile strength, allowing for the construction of structures such as slabs, driveways, and pavements. By providing uniform support to the concrete, the welded wire fabric minimizes cracking and improves the overall durability of the structure.

In the construction industry, welded wire mesh is also popular for forming walls and fences. Its sturdy construction makes it ideal for security fencing around properties, construction sites, and agricultural areas. The welded design prevents the wires from unravelling, ensuring that the fence remains intact and provides the necessary security.

Additionally, WWF finds applications in the forming of reinforcement cages for columns and beams, providing additional support where it is needed most. It is also used in the production of precast concrete products, enabling manufacturers to create items like retaining walls and stairs with enhanced strength and reliability.

Benefits of Using Welded Wire Fabric

One of the primary benefits of welded wire fabric is its ease of installation. Unlike traditional rebar, which requires specific tying and placement, WWF can be laid out and positioned much more quickly, saving on labor costs and construction time. Furthermore, its uniform grid pattern allows for consistent spacing, which simplifies the placement process.

Another significant advantage is its strength. The welding process creates a strong bond at each intersection, which provides improved load distribution across the fabric. This characteristic is crucial in applications where the structure must withstand heavy loads and stresses.

welded wire fabric

Welded wire fabric is also resistant to corrosion, particularly when galvanized or coated, extending its life in harsh environments. This enhancement minimizes maintenance needs and can lower long-term costs for projects such as highway installations and industrial setups where exposure to moisture and chemicals are a concern.

Moreover, the versatility of welded wire fabric means it can be customized to meet specific project requirements. Variations in wire diameter, spacing, and coating options can be tailored to suit different applications, offering engineers and builders flexibility in design.

Considerations When Using Welded Wire Fabric

While welded wire fabric offers many benefits, there are some considerations to keep in mind. First, it is important to ensure that the correct specifications are chosen for a particular application. Factors such as load requirements, environmental conditions, and exposure to chemicals must be taken into account to select the appropriate type of WWF.

Proper handling and installation are also essential to avoid damaging the fabric. Although welded wire mesh is robust, mishandling during transport or placement can lead to distortions that may compromise its effectiveness as a reinforcement material.

Additionally, there can be limitations on the spacing and size of welded wire fabric, especially in situations where high tensile strength is required. In these cases, it may be necessary to combine WWF with other reinforcement methods, such as rebar, to achieve the desired structural integrity.

Conclusion

Welded wire fabric represents a fundamental component in modern construction, providing reliability, efficiency, and versatility. Its applications span a wide range of projects, from residential and commercial construction to industrial environments. With its many benefits, including enhanced strength, ease of installation, and customization options, welded wire mesh continues to be a preferred choice for builders and engineers alike. However, proper planning and consideration are necessary to ensure that it is used effectively, tailored to the specific needs of each project. As construction technologies advance, the role of welded wire fabric is likely to evolve, further shaping the landscape of the industry.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025