-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

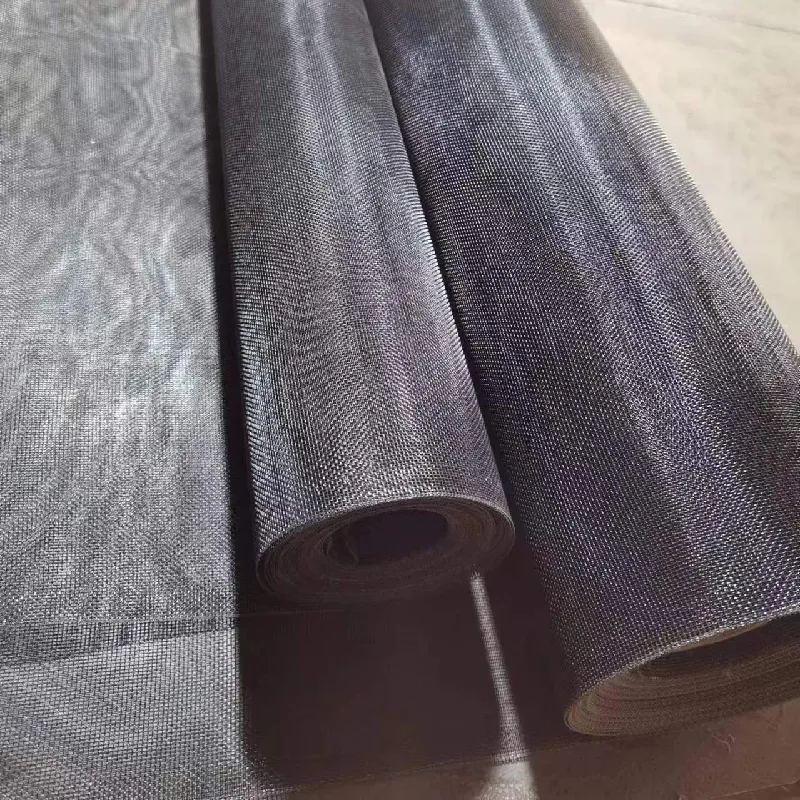

welded wire mesh

Understanding Welded Wire Mesh Applications, Benefits, and Features

Welded wire mesh is a versatile and widely used material in various industries, known for its excellent structural integrity and durability. Comprising a series of wire strands that are welded at each intersection, welded wire mesh is available in different dimensions and configurations, making it suitable for a multitude of applications, from construction to agriculture.

Composition and Manufacturing Process

Welded wire mesh is typically made from high carbon steel or galvanized steel, ensuring it can withstand various environmental conditions. The manufacturing process involves laying down horizontal and vertical wires in a grid pattern and welding them at each intersection using electric resistance welding. This method not only strengthens the mesh but also ensures uniform spacing, enhancing its structural reliability.

Applications of Welded Wire Mesh

1. Construction One of the primary uses of welded wire mesh is in construction. It serves as reinforcement in concrete, helping to distribute loads more evenly and reducing the risk of cracking. Concrete slabs, pavements, and walls often incorporate welded wire mesh for added strength and stability.

2. Fencing Welded wire mesh is commonly used for fencing purposes. Its robust construction provides security for residential, agricultural, and commercial properties. The mesh can be customized to different heights and thicknesses, making it easier to deter unwanted access while allowing visibility.

welded wire mesh

3. Agriculture In agricultural settings, welded wire mesh is utilized for creating protective enclosures for livestock and crops. It is an effective tool for keeping animals safe while also preventing pests from damaging plants. Additionally, it functions well in the construction of trellises and plant supports.

4. Industrial Uses In industrial settings, welded wire mesh is employed in the fabrication of partitioning systems, shelves, and safety barriers. Its durability makes it ideal for environments subject to heavy use and potential wear and tear.

Benefits of Welded Wire Mesh

The advantages of welded wire mesh are numerous. Its inherent strength and rigidity provide excellent load-bearing capacity, making it an efficient choice for various applications. Additionally, the welded construction minimizes the risk of unraveling or disbanding, unlike traditional wire fencing. The uniformity in wire spacing also allows for effective load distribution, enhancing safety and performance.

Furthermore, welded wire mesh is cost-effective and environmentally friendly. The manufacturing process generates minimal waste, and the materials used are often recyclable. Its long lifespan reduces the need for frequent replacements, making it a sustainable choice in both construction and farming.

Conclusion

In summary, welded wire mesh is an essential material that plays a significant role in multiple industries. Its robust nature, versatility, and economical benefits make it an attractive option for construction, fencing, agriculture, and industrial applications. Understanding its features and applications can greatly aid in making informed decisions when considering materials for projects or improvements in safety and infrastructure. Whether employed in large-scale construction projects or small agricultural settings, welded wire mesh proves to be a reliable and effective solution.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025