-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

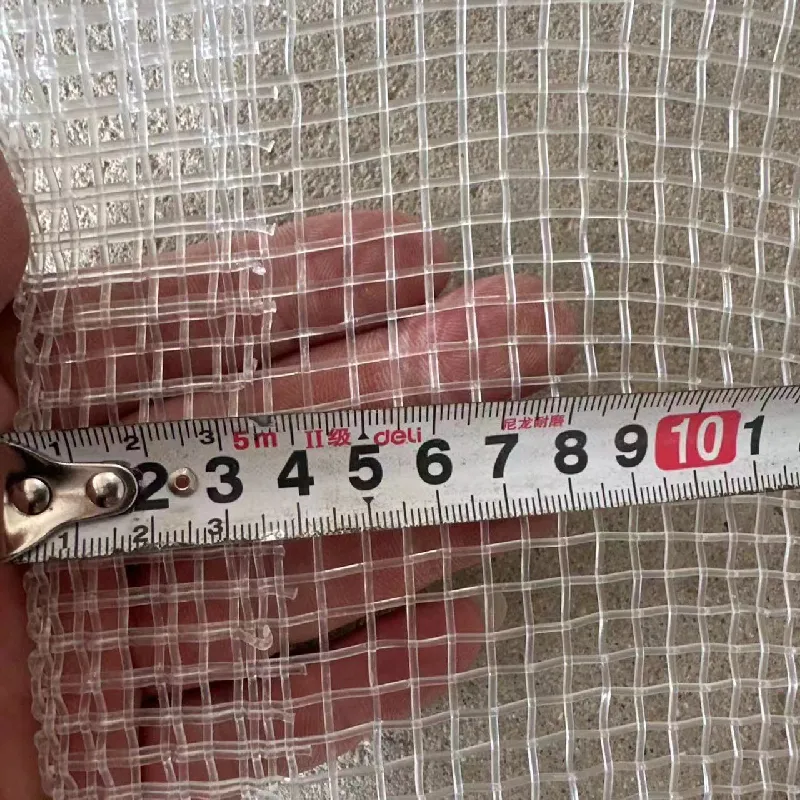

welding mesh price

Understanding Welding Mesh Prices Factors and Market Trends

Welding mesh, a versatile and durable product used in various applications such as construction, agriculture, and security, has seen a fluctuating market in recent years. Understanding the factors that influence welding mesh prices can help businesses and consumers make informed purchasing decisions.

1. Raw Material Costs

The primary component of welding mesh is steel, and its price is heavily influenced by the global steel market. Fluctuations in the price of raw materials, such as iron ore and coal, directly impact the cost of steel production. For instance, when there is an increase in demand for steel due to infrastructure projects or construction booms, steel prices tend to rise, subsequently affecting the cost of welding mesh. Conversely, a drop in steel prices often leads to lower welding mesh prices, making it more affordable for consumers.

2. Production Methods

The manufacturing process of welding mesh also plays a vital role in pricing. Different production methods, such as manual or automated welding, can influence labor costs and efficiency. Automated processes tend to reduce labor costs and increase production speed, allowing manufacturers to offer competitive prices. However, the initial investment in machinery can be high, which might be reflected in the pricing strategy. Manufacturers must balance efficiency with quality to maintain customer satisfaction without significantly raising prices.

3. Geographic Factors

welding mesh price

Location can significantly affect the price of welding mesh. Transportation costs are a crucial factor, as shipping large quantities of materials can be expensive. For example, welding mesh produced in regions with access to abundant raw materials may have lower prices due to reduced transportation costs. Conversely, importing welding mesh from distant manufacturers can increase overall costs, impacting the market price. Additionally, regional demand can vary; areas with high construction activity may see spikes in welding mesh prices due to increased local demand.

4. Market Demand

The overall market demand for welding mesh is influenced by various sectors, including construction, agriculture, and manufacturing. An increase in residential or commercial building projects often leads to a surge in demand for welding mesh, which can drive prices up. On the other hand, economic downturns or slowdowns in construction can lead to excess supply, causing prices to drop. Staying updated on market trends and forecasts can help consumers and businesses anticipate price changes.

5. Quality and Specifications

Finally, the quality and specifications of welding mesh also affect pricing. Higher-grade steel or specialty coatings that enhance durability and resistance to corrosion typically come at a premium price. Consumers must assess their specific needs and balance cost with quality to ensure they get the best value for their investment.

In conclusion, the price of welding mesh is influenced by a complex interplay of factors, including raw material costs, production methods, geographic considerations, market demand, and product specifications. By understanding these elements, buyers can make more informed decisions and potentially save money in the process. For those in the market for welding mesh, it is essential to stay informed about these dynamics to navigate the pricing landscape effectively.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025