-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

wire mesh filter manufacturers

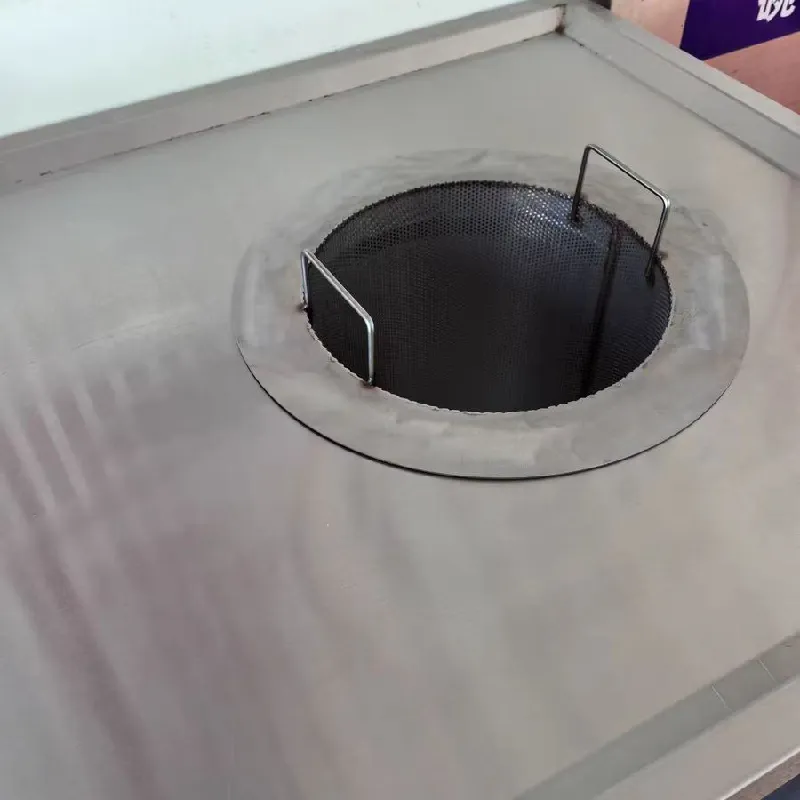

Exploring Wire Mesh Filter Manufacturers A Comprehensive Overview

In today's industrial landscape, the demand for efficient filtration systems has surged, leading to a significant rise in the number of wire mesh filter manufacturers

. These manufacturers play a crucial role in several industries, providing solutions that ensure the purity and quality of products while meeting regulatory requirements.Wire mesh filters are designed to remove particles from fluids or gases, making them essential in diverse applications ranging from water treatment to chemical processing and food production. The effectiveness of these filters largely depends on the material used, mesh size, and construction quality. As such, choosing a reliable manufacturer becomes paramount for businesses aiming to optimize their filtration processes.

When selecting a wire mesh filter manufacturer, it is essential to consider a few key factors

1. Quality of Materials The durability and performance of wire mesh filters hinge on the quality of materials utilized. Leading manufacturers often source stainless steel, brass, or nylon, each offering distinct advantages such as corrosion resistance and longevity. A reputable manufacturer will provide clear information regarding the materials used in their filters, ensuring they meet specific industry standards.

2. Customization Options Different industrial applications have unique filtration requirements. The best manufacturers offer customization options to meet varied specifications, such as size, shape, and mesh density. This flexibility ensures that clients receive filters tailored to their operational needs, ultimately enhancing efficiency.

wire mesh filter manufacturers

3. Certifications and Standards Wire mesh filters used in critical applications must comply with industry regulations. Reputable manufacturers often adhere to relevant certifications such as ISO 9001 or FDA approvals for food-grade applications. Ensuring that the manufacturer has these certifications can provide peace of mind regarding the product's safety and efficacy.

4. Experience and Reputation A manufacturer’s experience in the field can significantly impact product quality and service reliability. Established manufacturers with a solid track record are more likely to provide innovative solutions and reliable customer support. Researching customer reviews and case studies can offer insights into a manufacturer’s reputation.

5. Technical Support and Service After-sale support is vital for industries that rely heavily on filtration systems. A responsive customer service team and availability of technical support can help troubleshoot issues and ensure optimal filter performance over time. This ongoing relationship can greatly enhance operational efficiency and reduce downtime.

6. Cost-Effectiveness While price shouldn't be the sole determining factor, it is important to evaluate the cost-effectiveness of wire mesh filters. The initial investment should be weighed against the filter's lifespan, maintenance requirements, and overall performance. A balance between cost and quality will lead to the best return on investment.

In conclusion, as the industrial sector continues to evolve, the role of wire mesh filter manufacturers becomes increasingly significant. By focusing on quality, customization, compliance with standards, and exceptional support, businesses can find the right partners to enhance their filtration processes. In a world where efficiency and purity are paramount, investing in reliable wire mesh filters can lead to significant improvements in productivity and product quality. As manufacturers continue to innovate, the future of filtration looks promising, ensuring that industries can meet the rigorous demands of modern production challenges.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025