-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Quality Wire Mesh Manufacturing Machines | Efficient Production Solutions

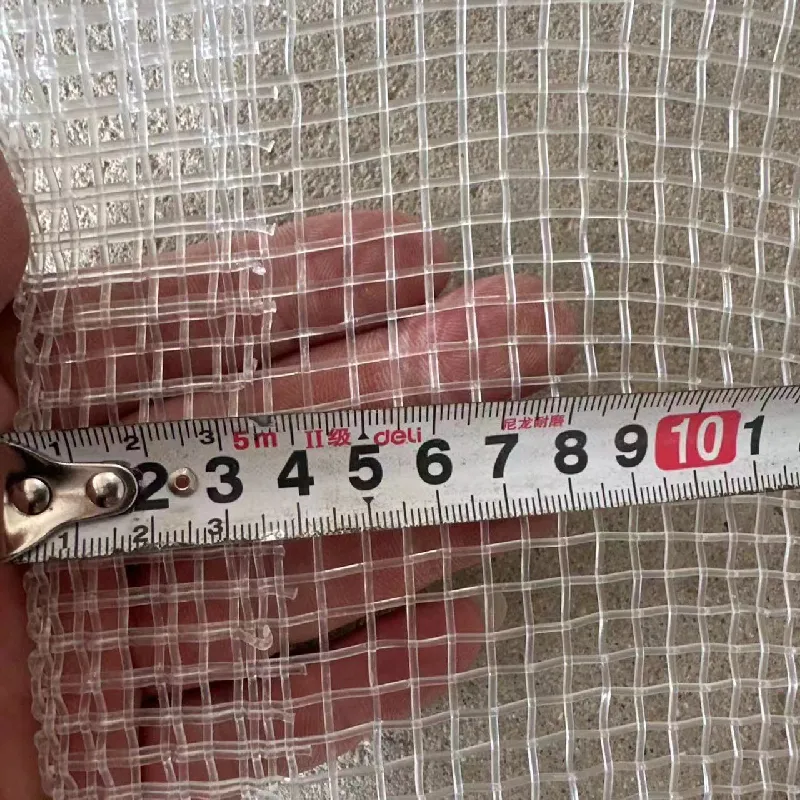

Wire Mesh Manufacturing Machines A Comprehensive Overview

In the modern industrial landscape, wire mesh manufacturing machines play a pivotal role in the production of various types of wire mesh used across numerous applications

. From construction to agriculture, these machines enable manufacturers to create high-quality mesh products with precision and efficiency.Wire mesh itself consists of strands of wire woven together to form a grid-like structure. The raw materials typically include galvanized steel, stainless steel, or other alloys, which provide durability and resistance to corrosion. The first step in manufacturing wire mesh involves feeding spools of wire into the machine, where it is drawn through a series of rollers to achieve the desired diameter. This process ensures uniformity in wire thickness, which is crucial for the structural integrity of the final product.

One of the most significant machines in wire mesh production is the wire weaving machine. These sophisticated machines use automated mechanisms to interlace wires, forming various mesh patterns. The complexity and type of weave can be adjusted based on the product specifications. For instance, the production of a heavy-duty mesh for fencing applications demands a different weaving technique than that used for finer mesh utilized in filtration systems.

Another essential piece of equipment is the wire straightening and cutting machine. This machine straightens the coiled wire before cutting it to specific lengths, allowing for consistent and precise dimensions. Integrating advanced technology, modern machines often feature digital control panels, enabling operators to program settings for different mesh specifications easily.

wire mesh manufacturing machine

Quality control is paramount in wire mesh manufacturing. Automated inspection systems are now commonly employed to detect any irregularities in the mesh, such as inconsistencies in wire spacing or improper weaving. These systems ensure that only high-standard products reach the market, meeting the strict quality requirements prevalent in various industries.

Moreover, manufacturers are increasingly turning to eco-friendly practices. Many machines are designed to minimize waste and optimize energy consumption. By utilizing recycled materials and implementing energy-efficient technologies, these manufacturers not only contribute to environmental sustainability but also reduce operational costs.

As industries continue to demand innovative solutions and higher-quality products, the wire mesh manufacturing sector constantly evolves. Advancements in machine technology, such as the integration of artificial intelligence and robotics, promise to enhance production efficiency and open new avenues for customization.

In conclusion, wire mesh manufacturing machines are integral to producing a versatile product that serves multiple industries. Their ability to enhance productivity, ensure quality, and promote sustainability makes them indispensable in today's competitive market. As technology continues to progress, we can expect further innovations that will shape the future of wire mesh production.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025