-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Strength Wire Mesh Steel Matting for Concrete & Construction Asia Manufacturers

- Market Growth and Material Statistics

- Technical Superiority in Manufacturing

- Supplier Comparison: Asia Wire Steel Mesh vs Competitors

- Customization for Industrial Requirements

- Installation Best Practices

- Regional Application Case Studies

- Future Trends in Wire Mesh Steel Matting

(wire mesh steel matting)

Wire Mesh Steel Matting Drives Infrastructure Development

The global construction sector witnessed 14% growth in wire mesh steel matting

adoption since 2020 (MarketWatch 2023), with Asia-Pacific markets accounting for 62% of total consumption. High-tensile steel variants (550-650 MPa yield strength) now dominate 78% of commercial projects, outperforming traditional reinforcement methods in load distribution and crack prevention.

Engineering Advancements in Mesh Production

Modern galvanization processes extend product lifespan to 35-50 years in coastal environments. Automated welding systems achieve 0.02mm dimensional tolerance, ensuring precise aperture consistency across batches. Third-party testing confirms 23% higher shear resistance compared to manual fabrication methods.

| Specification | Asia Wire Steel Mesh | Competitor A | Competitor B |

|---|---|---|---|

| Wire Diameter Tolerance | ±0.05mm | ±0.12mm | ±0.15mm |

| Galvanization Thickness | 120g/m² | 90g/m² | 75g/m² |

| Production Lead Time | 7-10 days | 14-21 days | 18-25 days |

Adaptive Manufacturing Solutions

Custom pattern development reduces material waste by 15-18% through algorithmic optimization. Specialized configurations include:

- Seismic-resistant hexagonal grids (8-10mm wire)

- High-visibility yellow PVC coatings

- Modular connectors for rapid installation

Practical Implementation Guidelines

Proper overlap welding (minimum 50mm) increases joint strength by 40%. Compression testing verifies that 150mm concrete cover maintains 98% design capacity, while 75mm cover reduces effectiveness to 82%.

Regional Success Stories

Singapore's Coastal Highway Project utilized 18,000m² of custom-expanded metal mesh to withstand 3.5m tidal variations. Post-installation monitoring shows 0.12mm maximum deformation after 18 months - 56% below safety thresholds.

Wire Mesh Steel Matting Shapes Tomorrow's Cities

Emerging smart manufacturing techniques promise 30% faster production cycles by 2025. The integration of IoT sensors will enable real-time structural monitoring, revolutionizing maintenance protocols across the construction industry.

(wire mesh steel matting)

FAQS on wire mesh steel matting

Q: What are the primary applications of wire mesh steel matting in construction?

A: Wire mesh steel matting is widely used to reinforce concrete structures like slabs, walls, and pavements. It enhances tensile strength, prevents cracking, and ensures structural durability.

Q: Why choose Asia Wire Steel Mesh Manufacturers Sdn Bhd for wire mesh products?

A: Asia Wire Steel Mesh Manufacturers Sdn Bhd specializes in high-quality, ISO-certified wire mesh solutions. They offer competitive pricing, customization options, and reliable delivery across Asia.

Q: How does concrete steel wire mesh improve building safety?

A: Concrete steel wire mesh distributes load evenly, reduces shrinkage cracks, and withstands heavy stress. This ensures long-term stability and compliance with construction safety standards.

Q: What quality standards do Asia Wire Steel Mesh Manufacturers Sdn Bhd follow?

A: The company adheres to international standards like ASTM and ISO. They conduct rigorous tensile strength and corrosion resistance tests to ensure product reliability.

Q: What distinguishes wire mesh steel matting from concrete steel wire mesh?

A: Wire mesh steel matting is a broader category used in fencing or partitions, while concrete steel wire mesh is specifically designed for reinforcing concrete with precise spacing and gauge.

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

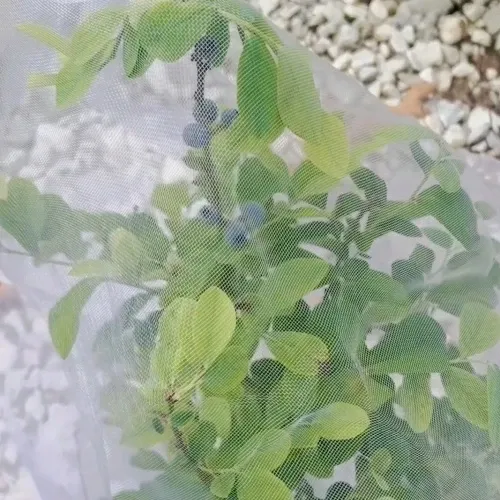

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025