-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 29, 2025 05:43

Back to list

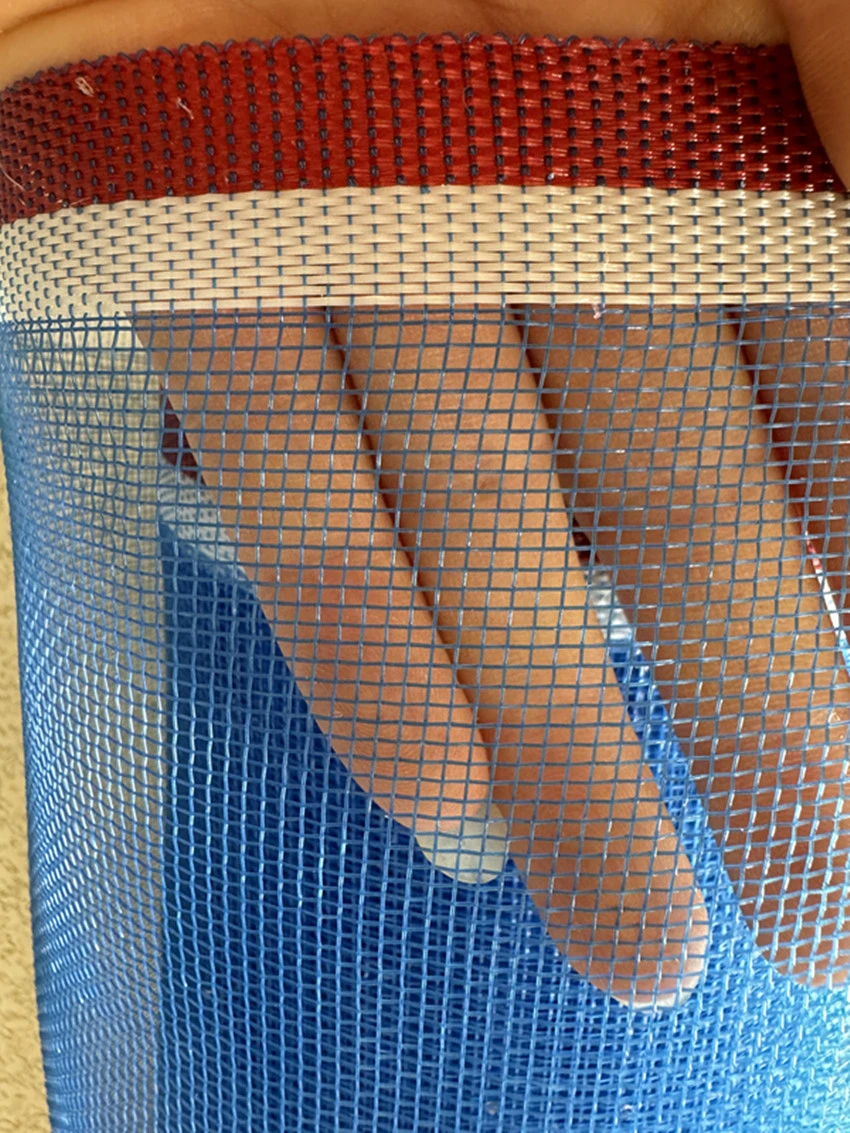

Welded Gabion Box 2x1x1 Hot Dipped Galvanized Welded Mesh Gabion

Wire mesh filters have long been an indispensable component in various industries due to their versatility and effectiveness. The unique characteristics of wire mesh filters make them increasingly popular across sectors such as manufacturing, automotive, food and beverage, pharmaceuticals, and more. When selecting a wire mesh filter, understanding the nuances of their design, material composition, and mesh size can significantly enhance operational efficiency and extend equipment longevity.

The authoritative use of wire mesh filters is evident in the automotive industry, where they are incorporated into oil, air, and fuel systems. These filters are essential in preventing engine damage by trapping contaminants and allowing for smoother, efficient operations. Ensuring the filter meets automotive industry standards is crucial, requiring adherence to specifications predetermined by automotive manufacturers. User experience with wire mesh filters can vary substantially based on the quality of the filter and the specific environment in which it operates. Durable wire mesh filters can result in reduced downtime and maintenance costs. Therefore, detailed guides and manuals provided by manufacturers significantly enhance user trust and ensure optimal maintenance and replacement cycles are followed. Trustworthiness in wire mesh filter choice also aligns with ethical sourcing and sustainable manufacturing processes. Manufacturers that invest in eco-friendly production and recycling practices not only bolster their reputation but also appeal to environmentally conscious consumers. Moreover, transparency in product testing and certifications adds another layer of reliability, spearheading lasting partnerships between suppliers and consumers. In conclusion, wire mesh filters are now more than ever a critical component across varied domains, owing to their adaptability and precision. Combining professional expertise with practical user insights secures an optimal filtering solution tailored to specific industrial needs. As industries continue to evolve, so too do the applications and innovations surrounding wire mesh filters. Understanding their composition, operational capacity, and industry requirements leads to improved efficiency and lower operational risks, establishing wire mesh filters as a backbone element in contemporary filtration systems.

The authoritative use of wire mesh filters is evident in the automotive industry, where they are incorporated into oil, air, and fuel systems. These filters are essential in preventing engine damage by trapping contaminants and allowing for smoother, efficient operations. Ensuring the filter meets automotive industry standards is crucial, requiring adherence to specifications predetermined by automotive manufacturers. User experience with wire mesh filters can vary substantially based on the quality of the filter and the specific environment in which it operates. Durable wire mesh filters can result in reduced downtime and maintenance costs. Therefore, detailed guides and manuals provided by manufacturers significantly enhance user trust and ensure optimal maintenance and replacement cycles are followed. Trustworthiness in wire mesh filter choice also aligns with ethical sourcing and sustainable manufacturing processes. Manufacturers that invest in eco-friendly production and recycling practices not only bolster their reputation but also appeal to environmentally conscious consumers. Moreover, transparency in product testing and certifications adds another layer of reliability, spearheading lasting partnerships between suppliers and consumers. In conclusion, wire mesh filters are now more than ever a critical component across varied domains, owing to their adaptability and precision. Combining professional expertise with practical user insights secures an optimal filtering solution tailored to specific industrial needs. As industries continue to evolve, so too do the applications and innovations surrounding wire mesh filters. Understanding their composition, operational capacity, and industry requirements leads to improved efficiency and lower operational risks, establishing wire mesh filters as a backbone element in contemporary filtration systems.

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025