-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

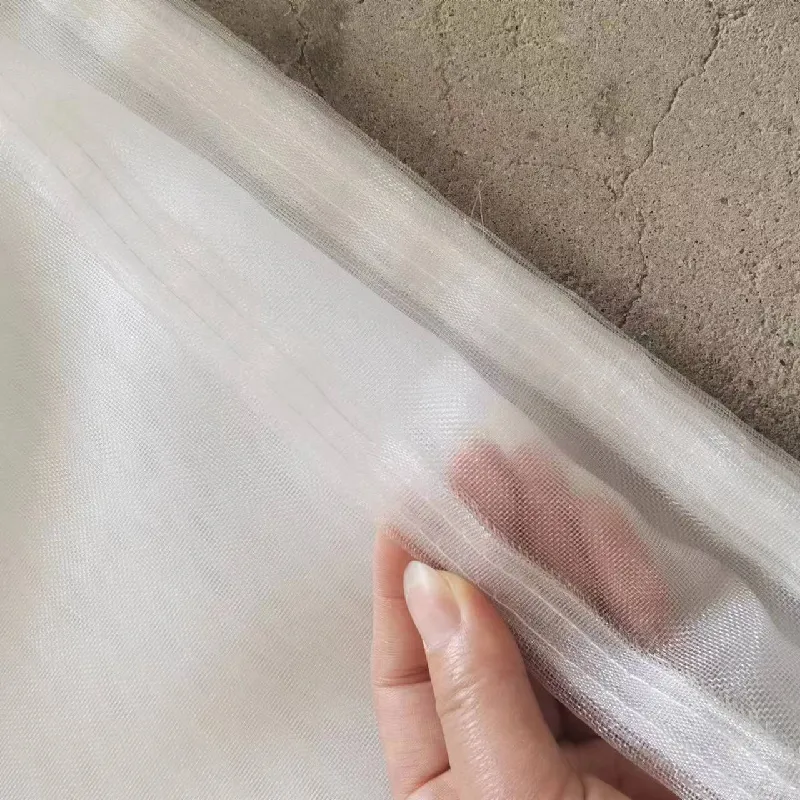

Durable Wire Mesh Steel Matting for Construction and Industrial Applications

Understanding Wire Mesh Steel Matting Applications and Benefits

Wire mesh steel matting has become an integral component across various industries due to its versatile applications and numerous benefits. This durable product, often constructed from high-quality steel, is designed to provide strength, support, and stability in a variety of settings. Understanding the characteristics, applications, and advantages of wire mesh steel matting can help industries make informed decisions for their specific needs.

What is Wire Mesh Steel Matting?

Wire mesh steel matting consists of a grid of interconnected wires that are welded together at specified intervals. This construction results in a strong and rigid mat that can be used for support, reinforcement, and safety purposes. The wire mesh is typically made from high-tensile steel that is resistant to rust and corrosion, making it suitable for both indoor and outdoor applications. Various gauges and mesh sizes are available to accommodate different load requirements and project specifications.

Applications of Wire Mesh Steel Matting

Wire mesh steel matting is utilized in numerous sectors, including

1. Construction In the construction industry, steel matting is primarily used for reinforcing concrete slabs and foundations. It enhances the structural integrity of buildings and bridges, preventing cracking and shifting over time.

2. Landscaping Homeowners and landscape architects often use wire mesh matting to create durable borders or retain soil. It provides stability for planting beds, retaining walls, and erosion control, helping to maintain the aesthetic integrity of outdoor spaces.

3. Agriculture In agricultural settings, wire mesh steel matting is used in fencing and as supports for crops. It helps in protecting livestock, maintaining crop layouts, and supporting climbing plants.

4. Industrial Applications Factories and warehouses utilize steel matting for flooring solutions, work surfaces, and safety barriers. The robust nature of the matting can withstand heavy machinery and foot traffic, reducing the risk of accidents.

wire mesh steel matting

5. Mining and Tunneling In mining operations, wire mesh matting is employed to support rock walls and prevent collapses in tunnels, ensuring worker safety and operational efficiency.

Advantages of Wire Mesh Steel Matting

The benefits of using wire mesh steel matting are substantial and can have a positive impact on both performance and cost-effectiveness

- Strength and Durability Made from high-tensile steel, wire mesh is incredibly strong and can bear heavy loads, making it an excellent choice for reinforcement applications.

- Cost-Effective Solution Due to its longevity and reduced maintenance needs, wire mesh steel matting can be a cost-effective option in the long run, minimizing replacement and repair costs.

- Flexibility Wire mesh matting can be customized in terms of size, thickness, and finish, allowing for tailored solutions that meet specific project requirements.

- Easy Installation The installation process of steel matting is relatively straightforward, leading to reduced labor costs and shorter project timelines.

- Environmental Resistance The rust and corrosion-resistant properties of steel ensure that the matting can withstand various environmental conditions, making it suitable for outdoor use.

Conclusion

Wire mesh steel matting is a reliable and versatile material that serves a multitude of purposes in modern industry. Its strength, durability, and flexibility make it an ideal choice for construction, agriculture, landscaping, and many other applications. Understanding its benefits can aid stakeholders in selecting the right materials for their projects, ultimately leading to safer, more efficient, and sustainable outcomes. Whether you're reinforcing a building, enhancing outdoor aesthetics, or ensuring safety in industrial settings, wire mesh steel matting stands out as a valuable resource.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025