-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 29, 2025 02:55

Back to list

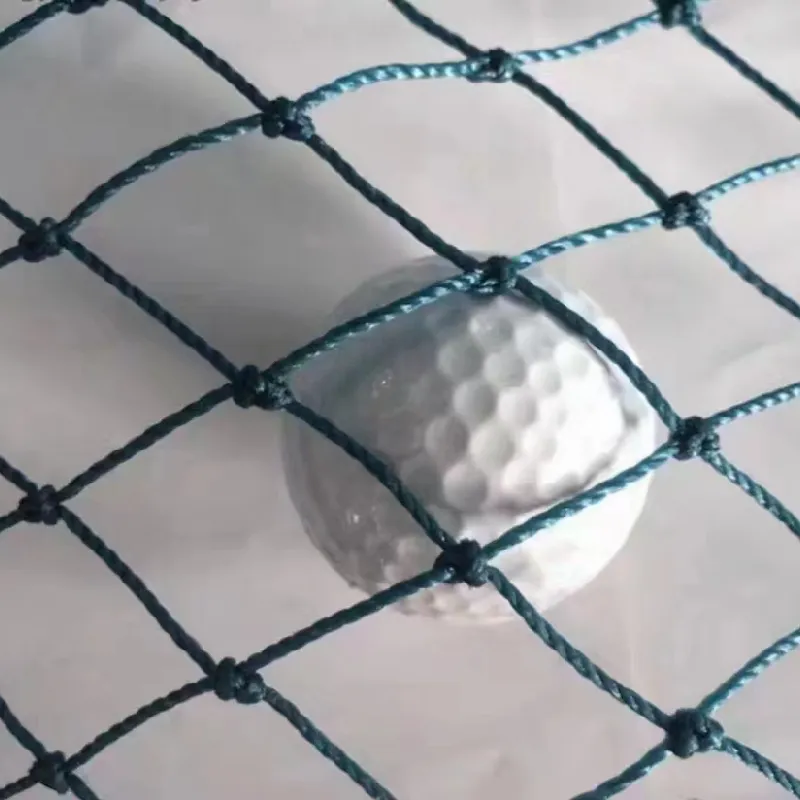

welded wire mesh

Wire mesh steel matting is a versatile and essential component used in multiple industries from construction to agriculture. Its unique blend of strength, flexibility, and durability has made it a favored choice among professionals looking to forgo traditional materials in demanding environments.

Mechanics and engineers often turn to wire mesh for industrial applications where filtration and separation are necessary. For instance, it can function in machinery as a filter to separate particles or contaminants from liquids. This attribute is crucial in maintaining the efficiency and longevity of equipment, preventing breakdowns that could lead to costly downtime. In these settings, wire mesh’s resistance to extreme temperatures and pressures further enhances its appeal. Expertise in selecting the right wire mesh steel matting can significantly influence the outcome of a project. Understanding the varying mesh sizes, wire thicknesses, and patterns available allows professionals to tailor materials specifically suited to their needs without compromising on quality or safety. This knowledge stems from an authority in the field of construction materials, where making informed decisions can lead to enhanced performance outcomes. Few materials can rival the reputation of wire mesh steel matting established over several decades. Its trustworthiness is derived from consistent performance and a track record for excellence across multiple domains. Industries have standardized against it because it offers a predictable and calculable outcome, reducing the variable factors that often accompany the use of lesser-known materials. In summary, wire mesh steel matting combines experience-tested reliability with the expertise-informed choice, making it a cornerstone material across diverse industries. Its authoritativeness is reflected in its widespread adoption and proven results in structural integrity, safety, and efficiency. When considering material options that guarantee long-lasting performance and versatility, wire mesh steel matting stands out as a key component that professionals trust.

Mechanics and engineers often turn to wire mesh for industrial applications where filtration and separation are necessary. For instance, it can function in machinery as a filter to separate particles or contaminants from liquids. This attribute is crucial in maintaining the efficiency and longevity of equipment, preventing breakdowns that could lead to costly downtime. In these settings, wire mesh’s resistance to extreme temperatures and pressures further enhances its appeal. Expertise in selecting the right wire mesh steel matting can significantly influence the outcome of a project. Understanding the varying mesh sizes, wire thicknesses, and patterns available allows professionals to tailor materials specifically suited to their needs without compromising on quality or safety. This knowledge stems from an authority in the field of construction materials, where making informed decisions can lead to enhanced performance outcomes. Few materials can rival the reputation of wire mesh steel matting established over several decades. Its trustworthiness is derived from consistent performance and a track record for excellence across multiple domains. Industries have standardized against it because it offers a predictable and calculable outcome, reducing the variable factors that often accompany the use of lesser-known materials. In summary, wire mesh steel matting combines experience-tested reliability with the expertise-informed choice, making it a cornerstone material across diverse industries. Its authoritativeness is reflected in its widespread adoption and proven results in structural integrity, safety, and efficiency. When considering material options that guarantee long-lasting performance and versatility, wire mesh steel matting stands out as a key component that professionals trust.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025