-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

wire mesh welding machine

The Importance of Wire Mesh Welding Machines in Modern Manufacturing

In the realm of modern manufacturing, efficiency, precision, and innovation are key factors that dictate the success of any production process. One of the unsung heroes in this industrial environment is the wire mesh welding machine. This sophisticated piece of equipment plays a crucial role in the construction and manufacturing industries, where the demand for durable and reliable wire mesh products is rising steadily.

Understanding Wire Mesh Welding Machines

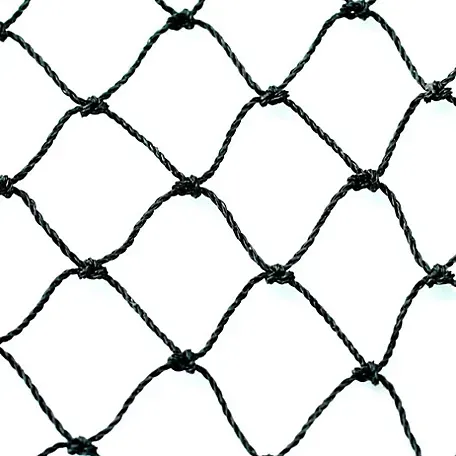

Wire mesh welding machines are specialized devices designed to create welded wire mesh panels. These panels are comprised of intersecting and welded wires, creating a lattice-like structure that is not only strong but also versatile. The welding machine utilizes advanced technology to automate the welding process, ensuring consistency in quality and precision in design.

These machines come in various configurations, including computerized systems that allow for programmable settings. This flexibility enables manufacturers to meet specific client requirements, from customized sizes to varying wire diameters and spacing. Moreover, modern machines are designed with user-friendly interfaces, making it easier for operators to control the process.

Applications of Wire Mesh in Various Industries

Wire mesh products have vast applications across multiple industries. In construction, they are used for reinforcing concrete, creating walls, and providing support for heavy structures. The automotive industry utilizes welded wire mesh in safety features, such as barriers and cages, ensuring the protection of both vehicles and passengers.

In agriculture, wire mesh fencing helps protect crops and livestock from predators. Additionally, in the environmental sector, wire mesh is used in filters and screens, proving its versatility across functions. These diverse applications highlight the necessity for high-quality wire mesh, produced efficiently through advanced welding technology.

The Advantages of Using Wire Mesh Welding Machines

wire mesh welding machine

The adoption of wire mesh welding machines brings numerous advantages to manufacturers. Firstly, these machines significantly improve productivity by reducing labor costs and speeding up the production process. Automated welding techniques minimize manual intervention, allowing for quicker turnaround times on large orders.

Secondly, the precision offered by modern welding machines ensures that every weld is uniform and reliable. This consistency not only enhances the strength of the final product but also minimizes the risk of defects, which can be costly and time-consuming to rectify.

Moreover, many machines are designed with energy efficiency in mind. This reduces the overall energy consumption during operation, leading to lower production costs and a smaller environmental footprint—important considerations in today’s eco-conscious market.

Innovations in Wire Mesh Welding Technology

The industry is continually evolving, with innovations leading to more sophisticated machines and processes. Recent developments include the integration of smart technology, allowing for real-time monitoring and adjustments during production. This means that manufacturers can identify and address issues quickly, ensuring that quality standards are met consistently.

Additionally, advancements in material science have introduced stronger and lighter wires, which can further enhance the qualities of the end products. As the demand for sustainable practices grows, some manufacturers are exploring the use of recycled materials in wire mesh production, promoting a circular economy.

Conclusion

Wire mesh welding machines are essential in the production of high-quality welded wire mesh products that serve various industries. Their role in enhancing productivity, ensuring quality, and promoting innovative practices cannot be overstated. As technology continues to evolve, these machines will undoubtedly become even more integral to the manufacturing process, providing solutions that meet the challenges of contemporary industrial demands.

In a world where quality and efficiency are paramount, investing in advanced wire mesh welding technology is not just a strategic move—it is a necessity for manufacturers aiming to thrive in a competitive landscape. Through the automation and precision offered by these machines, industries can maintain their edge and respond agilely to market needs, all while delivering exceptional products to consumers.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025