-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

woven stainless steel mesh

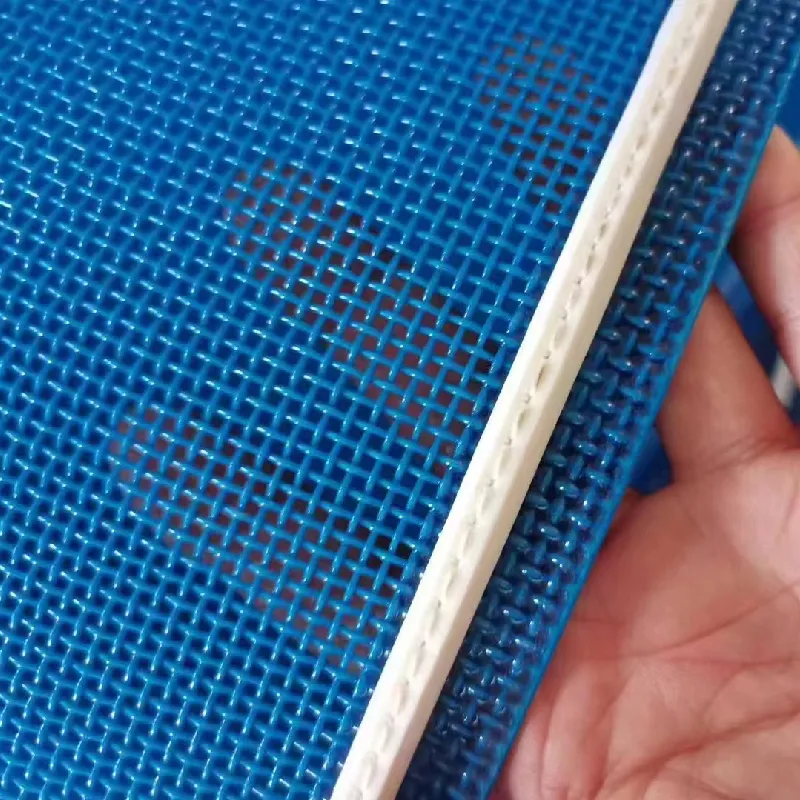

Exploring the Versatility of Woven Stainless Steel Mesh

Woven stainless steel mesh is a remarkable material that combines strength, durability, and versatility, making it the preferred choice for a myriad of applications across different industries. Its unique characteristics set it apart from other materials, providing solutions that are not only efficient but also sustainable.

At the core of woven stainless steel mesh is its construction. The weaving process involves interlacing stainless steel wires in a pattern that results in a robust yet flexible material. This method allows for varying levels of openness or porosity, which is crucial depending on the intended use, whether for filtration, reinforcement, or aesthetic purposes.

One of the most significant advantages of woven stainless steel mesh is its resistance to corrosion. Stainless steel, as an alloy, contains chromium, which forms a protective layer on the surface, preventing rust and degradation even in harsh environments. This property makes stainless steel mesh particularly suitable for outdoor applications, marine settings, or chemical industries where exposure to moisture and aggressive substances is commonplace.

In the industrial sector, woven stainless steel mesh is widely employed in filtration systems. Its ability to filter out particles while maintaining airflow or liquid flow is unparalleled. Industries such as food and beverage, pharmaceuticals, and water treatment rely heavily on this material for its effectiveness and safety. The mesh can be tailored to specific micron ratings, ensuring that the desired level of filtration is achieved while adhering to industry standards.

woven stainless steel mesh

Moreover, woven stainless steel mesh is often utilized in construction and architectural applications. Its strength provides structural support, while its aesthetic appeal can enhance designs. From decorative facades and railings to infill panels, woven mesh not only meets functional requirements but also contributes to the overall beauty of a structure. The versatility in design patterns and finishes allows architects and designers to push creative boundaries while ensuring safety and durability.

In the automotive and aerospace industries, woven stainless steel mesh plays a crucial role in component manufacturing and heat shielding. Its ability to withstand high temperatures and resist deformation under stress makes it an ideal choice for parts that demand reliability and performance. Additionally, its lightweight nature helps improve fuel efficiency in vehicles without compromising strength.

Another area where woven stainless steel mesh is gaining traction is in the realm of art and design. Artists and craftsmen are increasingly incorporating this material into their works due to its unique texture and formability. Whether it's for sculptures, installations, or functional art pieces, the mesh adds a contemporary touch while maintaining practicality.

Furthermore, the sustainability aspect of stainless steel cannot be overlooked. It is 100% recyclable, and its longevity means that products made from woven stainless steel mesh often have a long lifecycle, reducing waste.

In conclusion, woven stainless steel mesh exemplifies the fusion of functionality and aesthetics. Its diverse applications across various industries underscore its importance in modern manufacturing and design. With ongoing advancements in technology and materials science, the future of woven stainless steel mesh looks promising, paving the way for even more innovative uses that will continue to revolutionize the way we approach design and engineering challenges. Whether for industrial, architectural, or artistic purposes, woven stainless steel mesh stands as a testament to human ingenuity and adaptability.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025