-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

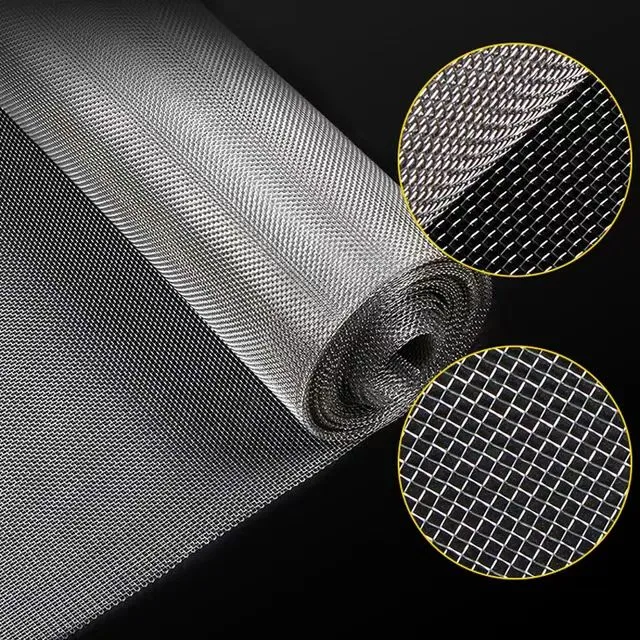

Durable Fabric Made from Woven Steel Mesh for Industrial Applications

The Versatility of Woven Steel Mesh in Modern Applications

Woven steel mesh is an innovative material that has garnered a considerable amount of attention across various industries. Characterized by its intricate interlacing of wires, this mesh offers a unique combination of strength, durability, and versatility that traditional materials often lack. As technological advancements push the boundaries of engineering and design, woven steel mesh has become an essential component in a multitude of applications, ranging from construction to the automotive and aerospace industries.

One of the primary advantages of woven steel mesh is its exceptional strength-to-weight ratio. The process of weaving the steel wires creates a network that distributes loads evenly, making it significantly stronger than comparable non-woven materials. This property is especially crucial in construction, where the integrity of structures relies on the materials used. Woven steel mesh is frequently employed in concrete reinforcement, providing added support to slabs, walls, and other structural elements. Its ability to enhance the tensile strength of concrete has made it a preferred choice among engineers looking to improve the durability and longevity of their projects.

In the automotive sector, woven steel mesh has found its niche as a protective and functional element in various components

. For instance, it is commonly used in heat shields, filters, and sound dampening systems. The mesh's high heat resistance and structural integrity allow it to withstand the harsh conditions of a vehicle's engine compartment while serving as an effective barrier against heat and noise. Additionally, its adaptability means that it can be tailored to meet specific requirements, such as varying mesh sizes and coatings, thereby enhancing its performance in different applications.woven steel mesh

The aerospace industry has also embraced woven steel mesh, particularly for components that require high strength-to-weight ratios. Aircraft design prioritizes lightweight materials to improve fuel efficiency, and woven steel mesh fits the bill perfectly. It is often incorporated into various structures, including fuselage frames and cargo floors, where its strength ensures safety without adding unnecessary weight. Moreover, woven steel mesh presents an aesthetically pleasing option for interior designs, allowing for creative applications that enhance both functionality and visual appeal.

Beyond these industries, woven steel mesh is used in the agricultural sector as fencing and protective barriers. Its durability and resistance to environmental factors make it an ideal choice for safeguarding crops from pests and animals. In addition, woven steel mesh is employed in filtration systems to separate solids from liquids, playing a crucial role in water treatment processes and industrial applications. The versatility of this material is unmatched, as it can be adapted to serve multiple purposes across various fields.

In conclusion, woven steel mesh stands out as a remarkable material that has transformed numerous industries through its strength, versatility, and durability. As engineers and designers continue to explore new applications and innovations involving this mesh, its significance in modern manufacturing and construction will only increase. The future looks bright for woven steel mesh, paving the way for advancements that prioritize performance and sustainability. Whether in the construction industry, automotive design, or aerospace engineering, woven steel mesh is undoubtedly a cornerstone of modern material science, illustrating the endless possibilities inherent in this remarkable creation.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025