-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Top Woven Wire Screen Manufacturers for Quality and Durability in Various Industries

Woven Wire Screen Manufacturers An Overview

Woven wire screens are essential components in various industries, serving a multitude of purposes ranging from filtration to material separation. The effectiveness and durability of these screens largely depend on the quality of materials used and the manufacturing processes employed. This article delves into the world of woven wire screen manufacturers, their roles, and the benefits they provide across different sectors.

What Are Woven Wire Screens?

Woven wire screens are made from metal wires woven together to create a mesh. The specifications of these screens can vary greatly depending on the intended application. They are widely used in industries such as mining, agriculture, food processing, and construction. Common applications include vibrating screens in the mining industry, sieves in food processing, and filters in water treatment facilities.

The Manufacturing Process

The manufacturing of woven wire screens involves several key steps, beginning with the selection of raw materials. Manufacturers typically utilize high-quality steel, aluminum, or other metals to ensure durability and resistance to wear. The wires are drawn to the desired gauge, after which the weaving process begins. Different weaving techniques, such as plain weave, twill weave, and dutch weave, can be employed, each offering unique characteristics suited to specific applications.

After weaving, screens undergo additional processes such as cutting, finishing, and surface treatments. Finishing can include galvanizing or coating, which enhances corrosion resistance and extends the lifespan of the product. Manufacturers must also perform quality checks to ensure that the screens meet industry standards and customer specifications. This multifaceted approach to manufacturing allows woven wire screen manufacturers to provide a product that is both effective and reliable.

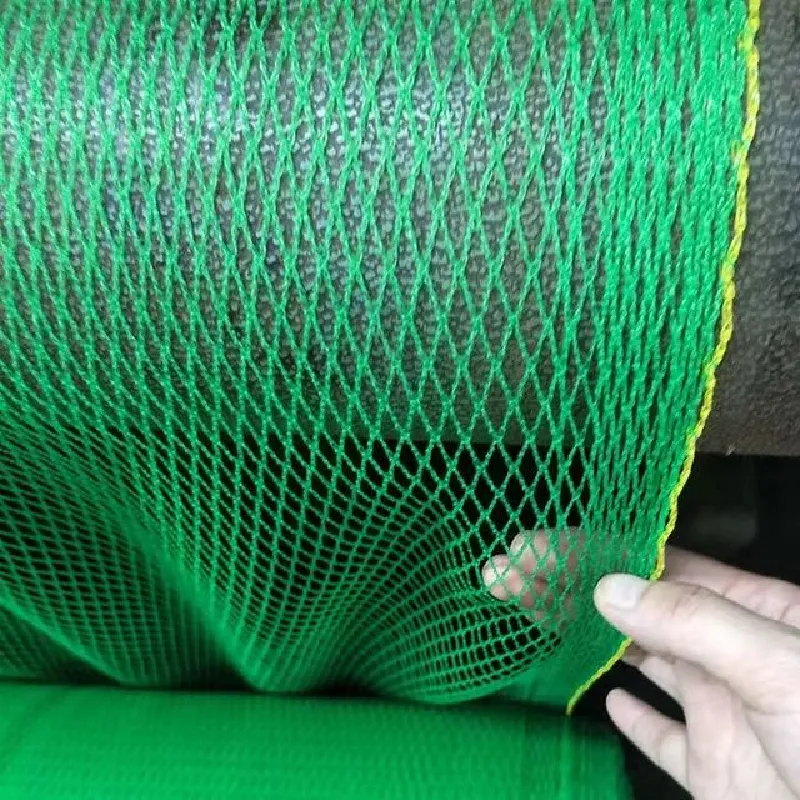

woven wire screen manufacturers

Qualities of a Good Manufacturer

When selecting a woven wire screen manufacturer, several attributes should be considered. Firstly, experience plays a crucial role; manufacturers with a long history in the market are likely to have refined their processes and developed specialized knowledge. Secondly, the range of products offered is important. A reputable manufacturer should provide a variety of materials, mesh sizes, and customization options to meet diverse customer needs.

Quality control is another essential aspect. Effective manufacturers implement stringent testing and quality assurance processes to ensure their screens perform under extreme conditions. Additionally, strong customer service and support are vital, as they help clients select the right products and provide after-sales assistance.

Sustainability Practices

In recent years, the focus on sustainability has intensified across industries. Woven wire screen manufacturers are increasingly adopting eco-friendly practices. This includes sourcing materials responsibly, utilizing energy-efficient manufacturing techniques, and recycling waste generated during production. Sustainable practices not only appeal to environmentally-conscious consumers but also contribute to the long-term viability of the manufacturing process.

Conclusion

Woven wire screens are integral to numerous industries, with their efficiency largely hinging on the expertise of manufacturers. From the selection of raw materials to the weaving process and quality assurance, every aspect of production plays a crucial role in the final product. When choosing a manufacturer, organizations should prioritize quality, experience, and sustainability practices. As industries evolve, so too will the demands for advanced woven wire screens, and manufacturers will need to adapt accordingly to meet these challenges. Overall, the significance of woven wire screen manufacturers cannot be overstated; they are vital partners in ensuring operational efficiency and success in various industrial applications.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025