-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

bolting cloth for screen printing

Understanding Bolting Cloth for Screen Printing

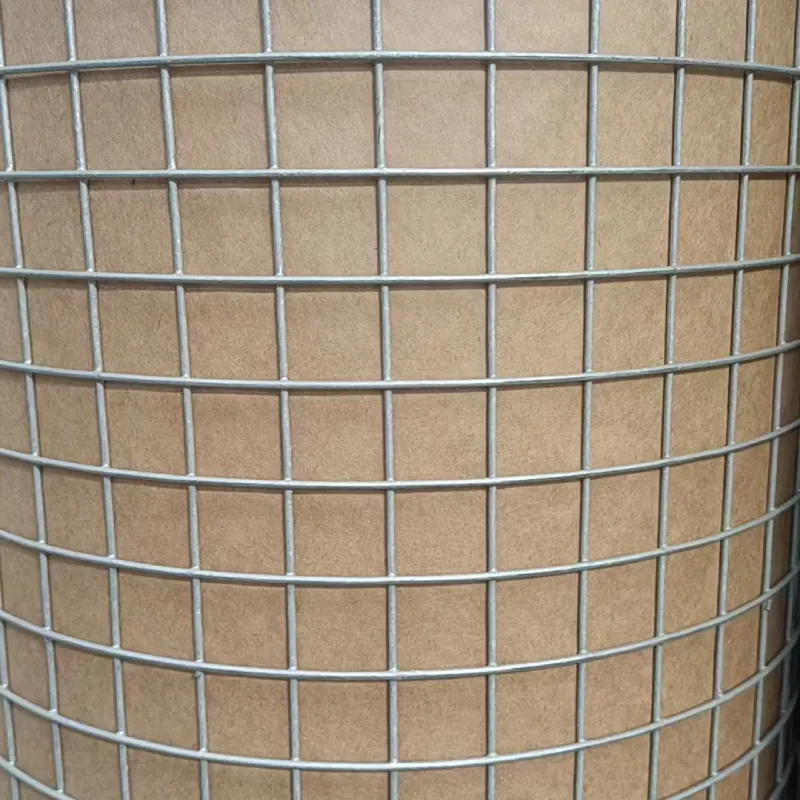

Bolting cloth, often referred to as screen mesh or simply mesh, is an essential component in the screen printing process. This specialized fabric plays a crucial role in determining the quality and precision of the printed images, making an understanding of its characteristics vital for anyone in the printing industry.

Understanding Bolting Cloth for Screen Printing

One of the key parameters in bolting cloth is mesh count, which refers to the number of threads per inch in both the horizontal and vertical directions. A higher mesh count results in a finer mesh that is capable of printing intricate designs. Conversely, a lower mesh count allows for thicker inks to pass through, making it suitable for bold and heavy designs. The mesh count selection is pivotal, as it directly affects the amount of ink that can be transferred during the printing process, ultimately influencing the opacity and detail of the final print.

bolting cloth for screen printing

In addition to mesh count, thread diameter also plays a significant role in the choice of bolting cloth. Thicker threads provide more durability but can hinder the ability to reproduce fine details, whereas thinner threads can deliver more intricate outputs but may wear out quicker. Finding the right balance based on the specific requirements of the job is crucial; for instance, artwork that demands high precision would benefit from a higher mesh count and thinner threads.

Another factor to consider is the weave type of the mesh. The two most common weaves are plain and twill. Plain weave is straightforward and provides uniform tension, while twill weave offers more flexibility and strength, making it suitable for a wider range of applications. The choice between these weaves influences the way ink is deposited on the substrate and can affect the overall quality of the final print.

The preparation of bolting cloth is equally important, as it often requires tensioning and coating with an emulsion to create the stencil for the design. Proper tensioning of the mesh ensures consistent ink transfer and helps maintain the integrity of the design. Additionally, the emulsion must be compatible with the ink being used, as different inks have varying chemical compositions.

In conclusion, bolting cloth is a fundamental element in screen printing that significantly impacts the quality of the printed product. Its characteristics such as mesh count, thread diameter, weave type, and preparation steps all play integral roles in achieving desirable results. Understanding these facets enables printers to make informed decisions that elevate their craftsmanship, resulting in prints that are not only visually stunning but also durable. Whether you are a novice or a seasoned professional in the world of screen printing, appreciating the nuances of bolting cloth will ultimately enhance your printing experience.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025