-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

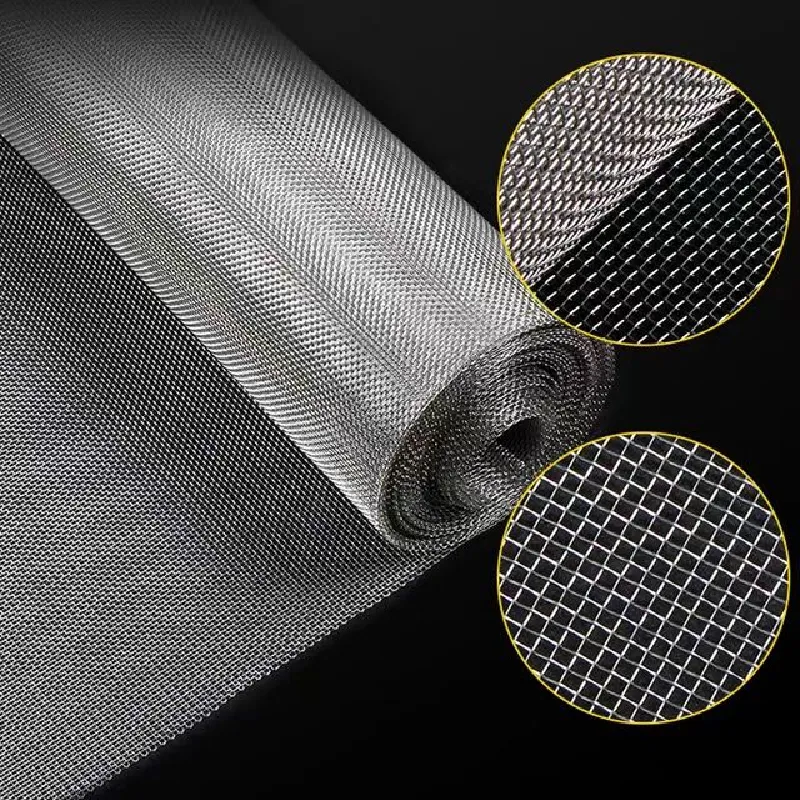

Durable Stainless Steel Woven Wire Mesh for Various Applications and Industries

Stainless Woven Wire Mesh An Indispensable Material in Modern Applications

In the realm of materials science and engineering, stainless woven wire mesh stands out as a highly versatile and valuable resource. Unlike standard wire, which is often limited in its applications, woven wire mesh can be tailored to meet a myriad of industrial needs. This article delves into the properties, manufacturing processes, and diverse applications of stainless woven wire mesh, highlighting its critical role in various sectors.

Properties of Stainless Woven Wire Mesh

Stainless woven wire mesh is made from stainless steel, an alloy that contains a minimum of 10.5% chromium, which grants it remarkable resistance to corrosion. This feature makes it especially suitable for environments where exposure to chemicals, moisture, and extreme temperatures is common. The durability and strength of stainless steel, combined with the unique weaving techniques employed in manufacturing, enable the mesh to withstand significant mechanical stresses. Furthermore, stainless woven wire mesh is available in various wire diameters and mesh sizes, allowing for customization based on specific filtration needs or structural requirements.

The openness of the mesh enables excellent airflow and light transmission while providing a barrier against larger particles, making it particularly useful in applications requiring filtration. Additionally, the aesthetic appeal of stainless steel gives this material a sleek, modern look, making it suitable for architectural applications as well.

Manufacturing Process

The manufacturing of stainless woven wire mesh involves several key stages. It starts with the selection of high-quality stainless steel wire, which is drawn to achieve the desired diameter. Once the wire is ready, it undergoes a weaving process. There are various weaving patterns, including plain weave, twill weave, and Dutch weave, each serving different functional purposes. For instance, plain weave is commonly used for filtration applications, while Dutch weave provides increased density, making it better suited for fine filtration.

Post-weaving, the mesh may undergo additional treatments, such as electropolishing or passivation, to enhance its corrosion resistance and improve overall aesthetic qualities. These processes remove impurities and result in a smooth, clean surface that not only looks good but also adds to the longevity of the product.

stainless woven wire mesh

Applications of Stainless Woven Wire Mesh

The applications of stainless woven wire mesh are extensive and varied, reflecting its versatility. In the food and beverage industry, it is used for filtration, sifting, and protection of equipment against contamination. Its corrosion resistance makes it ideal for processing and packaging applications where hygiene is paramount.

In the construction and architectural fields, stainless woven wire mesh serves as a decorative element in facades, railings, and screens. Designers appreciate the interplay of light and shadow created by the mesh, which can be employed both for functional and aesthetic purposes. Moreover, the strength of the material allows it to be used in structural applications, offering support while maintaining a transparent appearance.

Environmental engineering also relies on stainless woven wire mesh for various filtration systems, including water treatment and air filtration. The precise mesh openings help remove contaminants from liquids and gases, ensuring cleaner output for both industrial and residential needs.

Furthermore, the automotive and aerospace industries utilize stainless woven wire mesh for manufacturing components such as exhaust systems and heat shields. The ability of the mesh to withstand high temperatures and corrosive environments is essential for ensuring safety and performance in these highly regulated sectors.

Conclusion

In conclusion, stainless woven wire mesh is a crucial material that transcends mere functional use to become an integral part of countless applications across diverse industries. Its strength, durability, and aesthetic appeal make it an optimal choice for everything from industrial filtration to architectural design. As industries continue to innovate and advance, the demand for this versatile material is likely to grow, further solidifying its position as a cornerstone of modern engineering and design. Whether in a factory, a restaurant, or a contemporary building, stainless woven wire mesh illustrates how a simple material can play an essential role in our daily lives.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025