-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

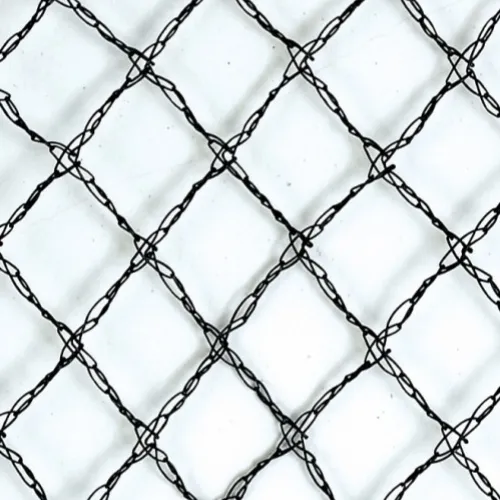

High-Quality Wire Mesh Steel Matting for Concrete Asia Wire Steel Mesh Manufacturers Sdn Bhd

- Introduction: Exploring the World of Wire Mesh Steel Matting

- Technical Specifications and Superior Advantages

- Comprehensive Manufacturer Comparison

- Tailored Solutions and Customization Options

- Application Case Studies Across Diverse Industries

- Economic and Sustainability Impact

- Conclusion: Advancing Infrastructure with Wire Mesh Steel Matting

(wire mesh steel matting)

Introduction to Wire Mesh Steel Matting and Its Increasing Demand

The construction and infrastructure landscape is evolving rapidly, driven largely by the integration of advanced reinforcement materials such as wire mesh steel matting

. This essential product has become a cornerstone for building robust, resilient, and cost-efficient structures. Wire mesh steel matting, crafted by systematic weaving or welding of steel wires, is designed for ultimate durability, easy installation, and precision in construction projects. Recent reports indicate that the global demand for wire mesh steel matting is surging, with the Asia Pacific region commanding nearly 47% market share in 2023, fueled by accelerated urbanization and government initiatives. Prominent providers, including Asia Wire Steel Mesh Manufacturers Sdn Bhd, contribute to setting international benchmarks. The adaptability of wire mesh steel matting is helping engineers achieve new milestones in safety, efficiency, and performance, revolutionizing how we approach concrete reinforcement in buildings, bridges, and industrial complexes.

Technical Specifications and Superior Advantages

Wire mesh steel matting stands out through a combination of robust tensile strength and flexible configuration. Manufactured most commonly in grades such as ASTM A1064/A1064M and BS 4483, these mesh panels are produced using either black or galvanized steel wire, offering both corrosion resistance and longevity. Mesh matting is available with varying wire diameters—typically ranging from 4mm to 12mm—and grid sizes from 50x50mm to 200x200mm to suit specific load-bearing needs.

One compelling technical advantage is its ability to evenly distribute applied loads, thereby minimizing crack widths in concrete by up to 40% compared to traditional rebar reinforcement. Installation time is significantly reduced: a team using welded steel mesh matting can complete slab reinforcement 25-30% faster than teams hand-tying bars. The pre-manufactured grids assure precision in placement, resulting in reduced material waste—studies estimate less than 2% wastage for large-scale projects, underscoring its economic value. Additionally, galvanized coatings protect against aggressive environmental conditions, extending the service life of critical infrastructure.

Comprehensive Manufacturer Comparison

The marketplace features a broad array of wire mesh steel matting producers. To provide a transparent view, here is a comparison of key specifications and differentiators among leading manufacturers, including Asia Wire Steel Mesh Manufacturers Sdn Bhd.

| Manufacturer | Location | Standards Met | Max Mesh Size (mm) | Wire Diameter Range (mm) | Surface Finish | Production Capacity (tons/year) | Lead Time (days) |

|---|---|---|---|---|---|---|---|

| Asia Wire Steel Mesh Manufacturers Sdn Bhd | Malaysia | BS 4483, ASTM A1064 | 6000x2400 | 4 - 12 | Galvanized, Black | 55,000 | 7-10 |

| CRH Reinforcement Europe | Germany | EN 10080, BS 4449 | 4000x2000 | 5 - 12 | Galvanized | 30,000 | 10-14 |

| Jiangsu Xingyin Steel Mesh Co., Ltd. | China | GB/T 700, ASTM A1064 | 6000x2200 | 4 - 10 | Black | 75,000 | 10-15 |

| Liberty Steel Mesh | Australia | AS/NZS 4671 | 6000x2400 | 4 - 14 | Galvanized, Black | 40,000 | 8-12 |

As shown, Asia Wire Steel Mesh Manufacturers Sdn Bhd distinguishes itself with rapid delivery, compliance with demanding international standards, and versatility in both wire gauge and mesh sizing. Customers from infrastructure, commercial, and water resource sectors value the consistency and superior yield that top manufacturers deliver.

Tailored Solutions and Customization Options

Construction innovation is driven by adaptability, and modern suppliers of concrete steel wire mesh are meeting complex demands with a range of customizable options. Customization can involve precise adjustment of weld patterns, mesh aperture, thickness, panel size, and steel grade to fit project-specific structural requirements. It is possible to order mesh rolls for rapid roadwork installation, or bespoke sheets pre-shaped and cut for unique architectural forms.

For large commercial developments and bespoke projects, manufacturers now offer digital pre-planning tools, including 3D mesh modeling and BIM integration. These resources enable precise cost projections and timeline optimization before fabrication. Clients benefit from tailored technical consultancy, ensuring the selected wire mesh steel matting harmonizes with site conditions and target load capacities. Further, additional coating selections—such as epoxy finishes—are available for highly corrosive environments like coastal or wastewater treatment projects.

The option for barcoding each mesh panel enhances traceability from plant to site, crucial for quality control and regulatory compliance. This level of product customization is essential for projects seeking LEED or BREEAM environmental certification, where waste minimization and material transparency are critical.

Application Case Studies Across Diverse Industries

The true measure of wire mesh steel matting’s impact is evident in landmark projects across various sectors. In bridge engineering, accelerated deck slab projects in Southeast Asia have utilized high-tensile mesh to cut construction periods by three weeks—enabling contractors to reopen key transportation links ahead of schedule.

Major commercial complexes, such as the 150,000-square-meter Suzhou International Expo Center, employed over 700,000 square meters of custom-shaped reinforcement mesh. This advanced reinforcement minimized slab cracking, resulting in less than 0.3% remedial work required post-cure. For high-rise towers, the use of lightweight mesh matting in multi-level parking zones has reduced dead loads by approximately 9%, improving design flexibility and overall seismic resistance.

In water management infrastructure, pre-coated mesh panels have been essential for lining large capacity containment tanks, dramatically increasing crack resistance and service durability under aggressive chemical exposure, as demonstrated by studies in Hong Kong's urban water treatment plants. Agricultural and mining industries also benefit: in soil stabilization and tunnel shaft linings, pre-formed mesh minimizes installation time and enhances long-term operational safety.

Economic and Sustainability Impact

The adoption of wire mesh steel matting is underpinned by quantifiable economic benefits. According to a 2023 industry analysis, substituting conventional rebar with pre-fabricated mesh can deliver overall project cost savings of 15-18% in labor and materials for multi-storey residential builds. Less waste, greater installation speed, and minimized rework collectively enhance profitability and project return on investment.

From a sustainability perspective, leading mesh products now leverage recycled steel content—some up to 85%—aligning with green building protocols globally. The reduction in truck deliveries and on-site cutting means that on average, CO2 emissions from steel reinforcement transport and handling are reduced by 26% for large civil infrastructure projects.

As urban developers and public sector clients increasingly prioritize sustainable procurement, transparent Environmental Product Declarations (EPDs) from suppliers drive broader adoption. Wire mesh steel matting’s closed manufacturing loop and reduced environmental footprint make it a compelling choice in contemporary construction.

Conclusion: Future-Proofing Construction with Wire Mesh Steel Matting

As infrastructure and building standards progress, the pivotal role of wire mesh steel matting becomes even more apparent. Its superior technical performance, verified through robust data across diverse climates and applications, empowers engineers and investors to deliver safer, longer-lasting, and more cost-efficient projects. With continued advancements from innovators like Asia Wire Steel Mesh Manufacturers Sdn Bhd, customization capabilities, and proof through real-world case studies, the future of concrete reinforcement is poised for sustained growth. Selecting the right concrete steel wire mesh solution enables every industry stakeholder to confidently embrace new challenges and opportunities in the global built environment.

(wire mesh steel matting)

FAQS on wire mesh steel matting

Q: What is wire mesh steel matting used for?

A: Wire mesh steel matting is commonly used to reinforce concrete in construction projects. It provides structural strength and prevents cracking in slabs and walls. Many builders choose it for durability and cost-effectiveness.Q: Who are prominent suppliers of wire mesh steel matting in Asia?

A: Asia Wire Steel Mesh Manufacturers Sdn Bhd is a recognized supplier in the region. They specialize in providing high-quality mesh solutions for various industries. Their products are widely used across construction projects in Asia.Q: How does concrete steel wire mesh improve building safety?

A: Concrete steel wire mesh helps distribute load and enhances the stability of concrete structures. It minimizes the risk of cracks and collapse due to heavy loads or environmental factors. This makes buildings safer and more durable.Q: Is wire mesh steel matting easy to install in construction projects?

A: Yes, wire mesh steel matting is designed for easy handling and installation. Its flexible structure allows for quick placement and reduces labor time. This efficiency is why it's preferred on many building sites.Q: What are the standard sizes of concrete steel wire mesh available?

A: Concrete steel wire mesh typically comes in standard sheets or rolls with varying mesh sizes. Manufacturers like Asia Wire Steel Mesh Manufacturers Sdn Bhd offer customization to fit project needs. Always consult the supplier for available options and technical specifications.-

Optimal Fish Rearing with Premium Breeding Net SolutionsNewsJul.18,2025

-

High-Strength Construction Wire Mesh for Structural Integrity and SafetyNewsJul.18,2025

-

Ensuring Protection and Efficiency in Construction and StorageNewsJul.18,2025

-

Enhancing Crop Protection with High-Quality Agriculture Shade NetsNewsJul.18,2025

-

Dunnage Bags and Shipping Plastic Bags for Secure TransportNewsJul.18,2025

-

Comprehensive Protection for Construction and InfrastructureNewsJul.18,2025