The material has strong toughness, is strong and wear-resistant, can withstand the scratching of pets, and has a long service life.

Clear material, easy to clean:

Made of transparent raw materials, the product has a clear texture, and visible dirt, and is easier to rinse.

Recommended for raising chickens, ducks, and geese: 1.2cm 1.8cm (recommended for adults: 1.8cm 2.5cm)

Recommended balcony protection to prevent cats from jumping off the building: 0.8 cm 1.2 cm 1.8 cm 2.5 cm

Recommended pet foot pads: 0.6 0.8 1.2 cm

Beekeeping net aquaculture recommended: 0.3 cm 0.6 cm

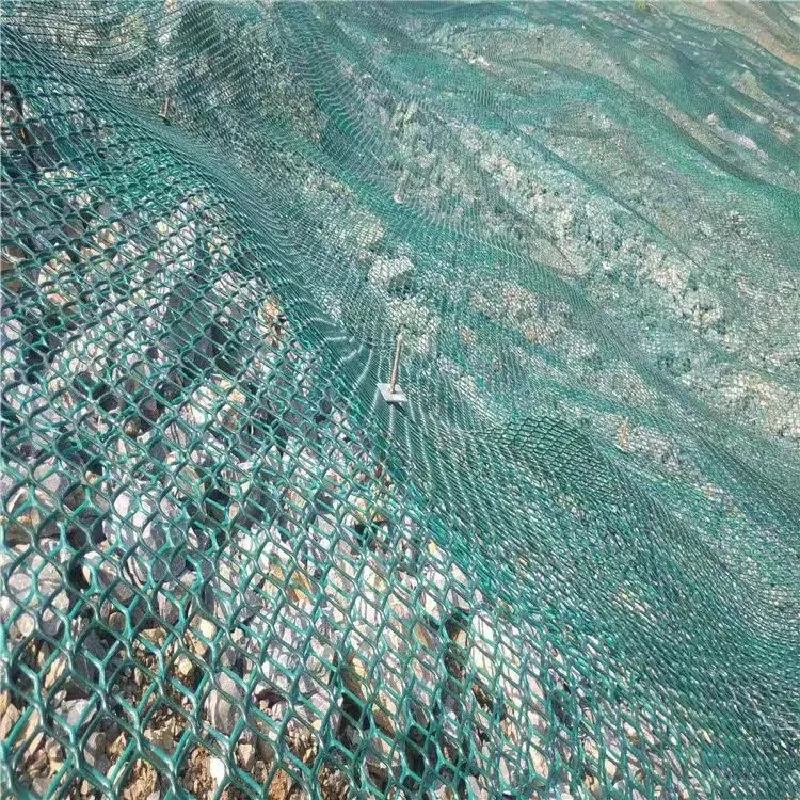

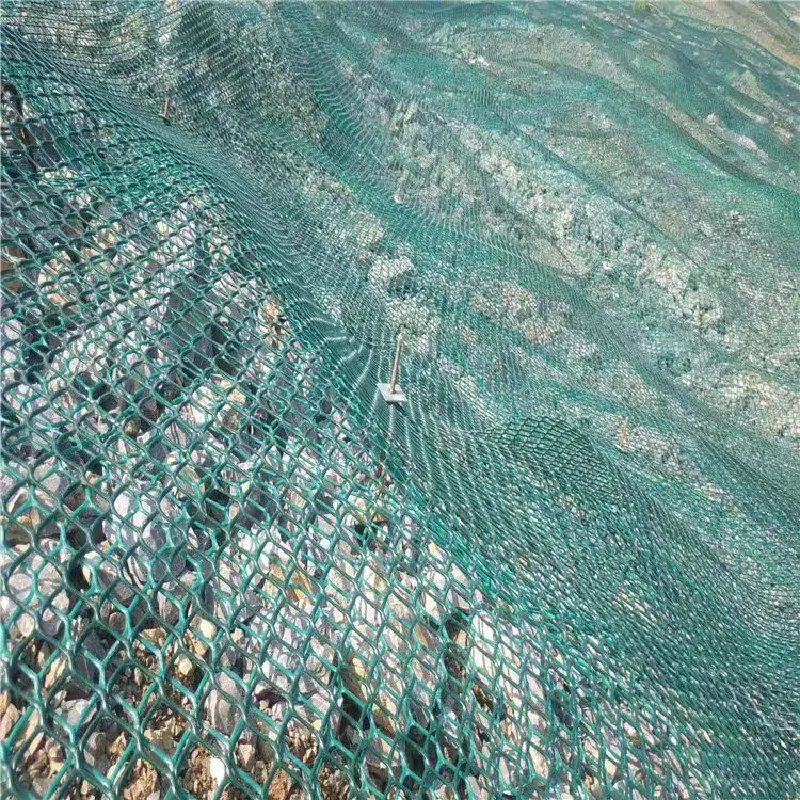

Pickled ore veneer recommendations: 1 cm 1.2 cm

Baked goods: 0.3 cm 0.6 cm 0.8 cm 1.2 cm

Mesh: 0.2 cm 0.3 cm 0.6 cm 0.8 cm 1.2 cm 1.8 cm 2.5 cm 3 cm 5 cm [Mesh size measurement ±2 mm error]

Width: 1 meter 1.2 meters 1.5 meters 2 meters 2.5 meters 3 meters [can be cut to any width within 3 meters]

Color: white green blue gray black red [customized colors supported]

Length: 50 meters per bundle [Length can be customized]

Can be cut into mesh according to your size

Versatile Plastic Flat Net for Manufacturing and Construction

Plastic flat net are highly versatile materials widely applied in manufacturing and construction industries. Their lightweight yet durable structure makes them ideal for applications where strength, flexibility, and corrosion resistance are critical. These nets provide cost-effective and efficient solutions for a range of industrial and structural purposes.

In the automotive sector, plastic flat mesh is used in manufacturing car backrests, headrests, and other interior components. Its flexibility allows it to be molded into custom shapes while maintaining strength and durability. Similarly, in construction projects, plastic flat net is employed for road base networks, temporary scaffolding partitions, and ventilation systems. Its ability to withstand harsh environments ensures long-term performance without frequent replacement.

Plastic flat net is also widely used in HVAC systems, such as air-conditioning networks. The mesh structure facilitates proper airflow while acting as a protective barrier against debris. This feature is critical for maintaining the efficiency and longevity of heating, ventilation, and air-conditioning equipment. By using plastic flat mesh, installers can create lightweight, easy-to-maintain systems that comply with industry standards.

In addition, plastic flat mesh is utilized in manufacturing packaging solutions, assembly line dividers, and protective panels for machinery. Its durability allows it to absorb impact, reduce damage, and protect both equipment and personnel. The easy installation and flexibility of plastic flat net make it a practical choice for both temporary and permanent industrial solutions.

The advantages of plastic flat mesh extend beyond durability. It is corrosion-resistant, lightweight, and cost-effective, making it suitable for indoor and outdoor applications. Its adaptability allows engineers and manufacturers to implement innovative solutions that improve productivity, reduce labor costs, and enhance operational efficiency.

In conclusion, plastic flat net offer versatile applications across manufacturing and construction sectors. From automotive components and air-conditioning networks to road base reinforcement and assembly line protection, these nets combine strength, durability, and adaptability, making them an indispensable material for modern industrial projects.

Plastic Flat Mesh Solutions for Pickling, Baked Goods, and Food Processing

Plastic flat mesh are essential materials in the food processing industry, including pickling, baking, and other industrial applications. Their durability, hygienic properties, and resistance to chemicals make them ideal for use in environments that require strict food safety standards.

In pickling operations, plastic flat mesh is used to separate and support raw materials in tanks or trays. Its non-corrosive properties ensure it can withstand acidic solutions without degradation, maintaining product quality over time. Similarly, in baked goods production, plastic flat net is used as support layers, drying racks, and conveyor belts, allowing proper air circulation while preventing direct contact with potentially contaminating surfaces.

Plastic flat mesh also excels in food packaging and processing lines. It can be used for washing, draining, and transporting fruits, vegetables, and other food items. The lightweight and flexible nature of plastic flat net allows easy handling, cleaning, and repeated use, significantly reducing operational costs and labor.

Hygiene and safety are critical in food applications, and plastic flat mesh provides a smooth, non-porous surface that resists bacterial growth. Its corrosion resistance and chemical stability ensure that it can be used with various food additives, cleaning agents, and processing solutions without compromising safety. Additionally, the mesh design allows liquids to drain efficiently, reducing drying time and improving production efficiency.

Beyond pickling and baking, plastic flat mesh finds use in aquaculture food processing, industrial drying racks, and filtration systems in food plants. Its multi-functional applications highlight its versatility and reliability in demanding environments. By integrating plastic flat net into processing workflows, manufacturers can ensure consistent quality, optimize production, and maintain compliance with food safety regulations.

In conclusion, plastic flat net are indispensable tools for pickling, baked goods, and food processing industries. Their durability, chemical resistance, and hygienic design provide safe, efficient, and cost-effective solutions, improving workflow, product quality, and operational efficiency.

High-Quality Plastic Flat Net for Mattresses, Air-Conditioning Networks

Plastic flat mesh are versatile and durable materials widely used in home products and industrial applications. Their lightweight, corrosion-resistant, and flexible properties make them ideal for applications such as mattresses, air-conditioning networks, road base nets, and more.

In the bedding industry, plastic flat mesh is used to reinforce mattress cores, providing structural stability while allowing airflow for comfort and ventilation. Its durability ensures long-term support, while its lightweight design facilitates easier assembly and transport. Plastic flat net also serves as protective inserts in cushions and other furniture components, enhancing durability without adding excessive weight.

In HVAC systems, plastic flat mesh plays a critical role in air-conditioning networks. It acts as a filter, barrier, and protective layer, allowing air to circulate while preventing debris and dust from entering sensitive equipment. The chemical and UV resistance of plastic flat net ensures long-term performance, even in outdoor or high-humidity environments.

Plastic flat mesh is also widely used in road construction and industrial manufacturing. It functions as reinforcement in road base networks, scaffolding protection, and various assembly lines. Its lightweight, corrosion-resistant properties make it ideal for long-term outdoor and industrial applications. Engineers and manufacturers rely on plastic flat net to improve safety, structural integrity, and operational efficiency.

Additionally, plastic flat mesh is simple to install, easy to maintain, and highly adaptable to custom designs. It can be cut, shaped, or molded according to specific application requirements, making it an ideal material for both home and industrial projects. Its versatility allows designers and manufacturers to implement innovative solutions that improve product performance and reduce labor costs.

In conclusion, plastic flat mesh provide reliable, durable, and multi-functional solutions for mattresses, air-conditioning networks, road construction, and other industrial applications. Their corrosion resistance, flexibility, and lightweight nature make them an indispensable material for modern manufacturing, construction, and home product industries.