-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

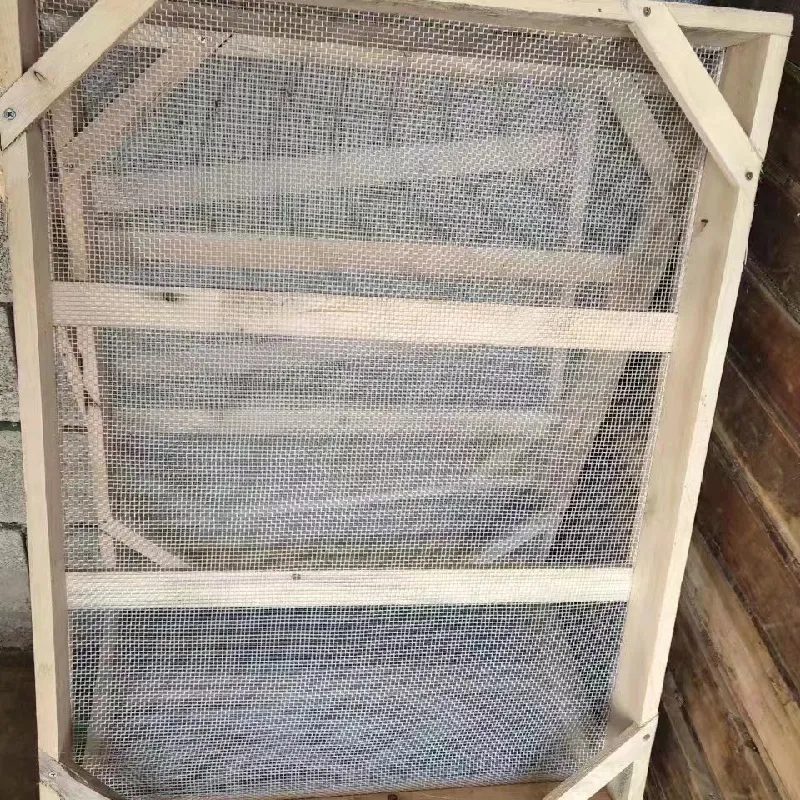

Corrosion-Resistant Steel Grids for Durable Construction Solutions

Understanding Galvanized Steel Grids Applications, Benefits, and Key Features

Galvanized steel grids have become an indispensable element in modern construction and various industrial applications. This article delves into what galvanized steel grids are, their numerous applications, the benefits they offer, and key features that make them a preferred choice among engineers and builders.

What is Galvanized Steel?

Before exploring the specifics of steel grids, it’s essential to understand what galvanized steel is. Galvanization is a process where steel is coated with a thin layer of zinc to protect it from corrosion and oxidation. This protective layer not only enhances the steel's durability but also extends its lifespan, making it suitable for use in harsh environmental conditions.

Structure of Galvanized Steel Grids

Galvanized steel grids are constructed using welded or riveted steel bars arranged in a crisscross pattern, creating a strong and stable support structure. The spacing between the bars can vary depending on the required load-bearing capabilities and specific application needs. Whether in fluid handling or load distribution, these grids are engineered to provide a robust solution that can handle a range of weights and pressures.

Applications of Galvanized Steel Grids

The versatility of galvanized steel grids allows for numerous applications across various industries

1. Construction In the construction sector, galvanized steel grids are often used for flooring, walkways, and stair treads. They provide safe, slip-resistant surfaces while allowing for drainage, which is crucial in wet conditions.

2. Industrial Flooring Many manufacturing and warehousing facilities utilize galvanized steel grids for walkways and industrial flooring due to their impressive load-bearing capabilities and resistance to heavy machinery traffic.

3. Oil and Gas In the oil and gas industry, these grids are often implemented in platforms, walkways, and scaffolding. Their corrosion resistance is particularly valued in this sector, where exposure to harsh chemicals and extreme weather is common.

4. Agriculture Agricultural applications also benefit from galvanized steel grids, which are used in buildings, animal enclosures, and equipment storage. Their durability helps to maintain a safe and functional environment for both livestock and crops.

5. Power Plants In power generation facilities, galvanized grids are employed for walkways, maintenance platforms, and safety barriers ensuring that personnel can access equipment without compromising safety.

galvanized steel grid

Benefits of Galvanized Steel Grids

The primary advantage of using galvanized steel grids lies in their corrosion resistance. The zinc coating acts as a barrier against moisture, oxygen, and other environmental factors that would typically lead to rust and deterioration of untreated steel. Additionally, galvanized steel grids offer

- High Strength-to-Weight Ratio They are robust yet lightweight, enabling easy installation and manipulation on-site. - Low Maintenance The longevity of galvanized steel reduces the need for frequent repairs or replacements, making it a cost-effective solution over time.

- Safety Features Many galvanized grid designs feature slip-resistant surfaces, making them ideal for areas where foot traffic is prevalent.

- Environmental Resistance Galvanized steel grids can withstand a range of industrial environments, including high temperatures, humidity, and exposure to chemicals.

Key Features to Consider

When selecting galvanized steel grids, several essential features should be considered

1. Load Capacity Understand the weight they will need to support and select grids that can adequately handle that load.

2. Surface Treatment Various surface finishes are available beyond standard galvanization, such as powder coating, which can provide additional aesthetic or protective benefits.

3. Customization Many manufacturers offer customization options tailored to specific project requirements, such as size, spacing, and design.

4. Standards Compliance Ensure that the galvanized steel grid meets relevant industry standards for safety and performance.

Conclusion

Galvanized steel grids are a quintessential element in various industries due to their exceptional durability, versatility, and cost-effectiveness. With applications ranging from construction to oil and gas, they provide reliable solutions to many engineering challenges. As infrastructure continues to grow and evolve, the role of galvanized steel grids will undoubtedly expand, making them an essential component for future developments.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025