-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

ian. . 20, 2025 01:17

Back to list

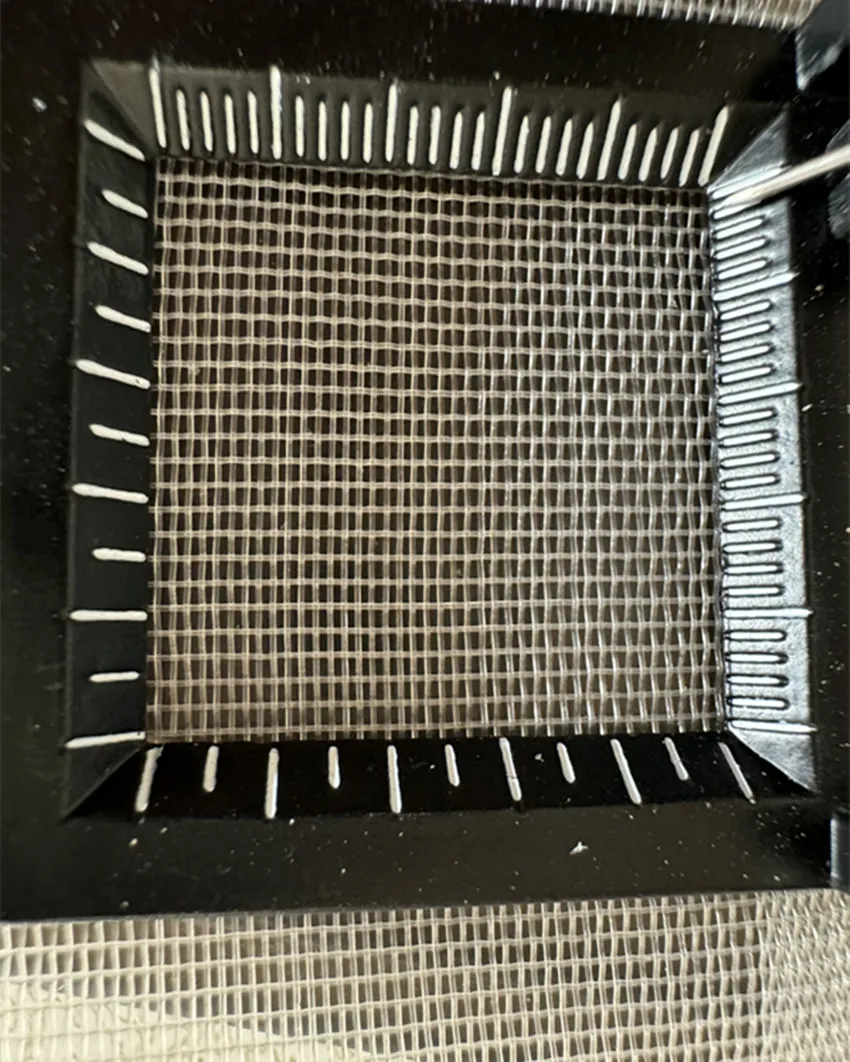

bird mesh

For those venturing into the realm of stainless steel materials, particularly the 304 stainless steel mesh, understanding its many applications and benefits is imperative for making informed purchasing decisions. The 304 stainless steel mesh has established itself as an indispensable component across various industries due to its remarkable properties and versatility. This article will delve into the practical experiences, the expertise behind its manufacture, its authoritative role in industries, and why it is a trustworthy choice for your needs.

The 304 stainless steel mesh also asserts authoritative credibility due to its compliance with international standards. Its adherence to ASTM and ISO certification criteria underlines its quality and reliability, paving the way for its widespread acceptance across global markets. In architectural applications, this mesh is often chosen to serve as an aesthetic element in building facades and interiors, owing to its ability to maintain structural integrity while allowing for an enhanced visual appeal. Architects and builders alike recognize its authority not only for its functionality but for the modern and sophisticated appearance it bestows upon structures. When it comes to trustworthiness, the 304 stainless steel mesh consistently surpasses expectations. Users frequently commend its performance, highlighting its unmatched ability to withstand mechanical stress without compromising on flexibility. Moreover, its sanitary properties make it a preferred choice in medical and laboratory environments, where sterility cannot be compromised. As professionals share their experiences, a common theme emerges investing in the 304 stainless steel mesh is synonymous with investing in reliability. Thus, the 304 stainless steel mesh emerges as a product underscored by experience-backed performance, expertise-driven manufacturing, authoritative industry acceptance, and an unwavering trustworthiness that makes it a cornerstone material across diverse applications. Whichever industry you belong to, integrating 304 stainless steel mesh into your processes assures not only enhanced efficiency and safety but also long-term satisfaction and return on investment. It remains unparalleled in delivering quality and versatility, thereby fortifying its position as the preferred choice of experts worldwide.

The 304 stainless steel mesh also asserts authoritative credibility due to its compliance with international standards. Its adherence to ASTM and ISO certification criteria underlines its quality and reliability, paving the way for its widespread acceptance across global markets. In architectural applications, this mesh is often chosen to serve as an aesthetic element in building facades and interiors, owing to its ability to maintain structural integrity while allowing for an enhanced visual appeal. Architects and builders alike recognize its authority not only for its functionality but for the modern and sophisticated appearance it bestows upon structures. When it comes to trustworthiness, the 304 stainless steel mesh consistently surpasses expectations. Users frequently commend its performance, highlighting its unmatched ability to withstand mechanical stress without compromising on flexibility. Moreover, its sanitary properties make it a preferred choice in medical and laboratory environments, where sterility cannot be compromised. As professionals share their experiences, a common theme emerges investing in the 304 stainless steel mesh is synonymous with investing in reliability. Thus, the 304 stainless steel mesh emerges as a product underscored by experience-backed performance, expertise-driven manufacturing, authoritative industry acceptance, and an unwavering trustworthiness that makes it a cornerstone material across diverse applications. Whichever industry you belong to, integrating 304 stainless steel mesh into your processes assures not only enhanced efficiency and safety but also long-term satisfaction and return on investment. It remains unparalleled in delivering quality and versatility, thereby fortifying its position as the preferred choice of experts worldwide.

Next:

Latest news

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025