-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

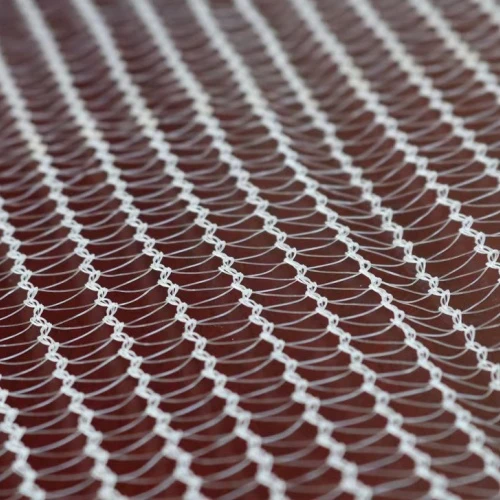

Innovative Solutions for Mesh Manufacturing Equipment and Techniques in Modern Production

The Evolution of Mesh Manufacturing Machines Revolutionizing Industries

In recent years, the landscape of manufacturing has undergone profound changes, driven by technological advancements and an ever-increasing demand for efficiency and precision. Among the innovations that stand out is the development of mesh manufacturing machines. These machines have revolutionized the way various materials, including metals, plastics, and textiles, are processed and transformed into meshes, serving a plethora of applications across multiple industries.

Understanding Mesh Manufacturing

Mesh manufacturing machines are specialized equipment designed to produce mesh products with specific material characteristics and structural integrity. These machines utilize various processes such as weaving, knitting, welding, and laser cutting to create meshes that feature precise hole patterns, thicknesses, and material types. The versatility of these machines allows for the production of both simple and complex mesh designs, accommodating diverse requirements ranging from industrial filtration and construction to automotive and aerospace applications.

Technological Advancements

The continuous evolution of technology has significantly impacted the design and functionality of mesh manufacturing machines. Innovations such as Computer Numerical Control (CNC) technology and automation have drastically increased precision in the manufacturing process. CNC machines provide the capability to produce intricate mesh designs with minimal human intervention, thus enhancing productivity while reducing the margin for error. Moreover, the integration of Industry 4.0 principles, such as IoT connectivity and data analytics, has enabled real-time monitoring and optimization of manufacturing processes, ensuring consistency and quality in the final products.

Additionally, advancements in materials science have led to the development of new types of mesh materials that offer superior characteristics, such as enhanced strength, corrosion resistance, and lightweight properties. This has expanded the application scope of mesh products, making them suitable for more demanding environments and uses.

Environmental Considerations

mesh manufacturing machine

As industries become increasingly aware of their environmental impact, the role of mesh manufacturing machines in sustainable manufacturing practices cannot be overlooked. Many modern machines are designed with energy efficiency in mind, using less power while maintaining high production rates. Furthermore, the ability to recycle materials into new mesh products reduces waste and supports a circular economy. By prioritizing sustainability in their operations, manufacturers can meet the growing consumer demand for eco-friendly products and practices.

Application Across Industries

The versatility of mesh manufacturing machines has led to their widespread use across various sectors. In the construction industry, mesh materials are utilized for reinforcing concrete, providing structural integrity while minimizing weight. In the automotive sector, mesh products are used for filtration systems and components that require lightweight yet durable materials. The aerospace industry, known for its stringent safety and performance standards, also benefits from high-strength mesh materials that contribute to overall vehicle efficiency.

Additionally, the medical field has seen the introduction of specialized mesh products used in surgical applications, such as hernia repairs and tissue scaffolding. These products must meet strict regulatory guidelines, further emphasizing the importance of precise and reliable manufacturing processes.

Future Prospects

Looking ahead, the future of mesh manufacturing machines is ripe with possibilities. As advancements in automation and artificial intelligence continue to unfold, the potential for greater efficiency and customization will likely drive further adoption of these machines across industries. Moreover, the increasing emphasis on sustainability will demand continuous innovation in both machine design and the materials used, guiding the direction in which the mesh manufacturing sector evolves.

In conclusion, mesh manufacturing machines represent a crucial element in the modern manufacturing landscape. Their evolution has not only enhanced production capabilities but has also contributed to the development of innovative materials and sustainable practices across industries. As technology continues to advance, the future holds promise for even more sophisticated mesh manufacturing solutions, positioning them at the forefront of industrial innovation.

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025