-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

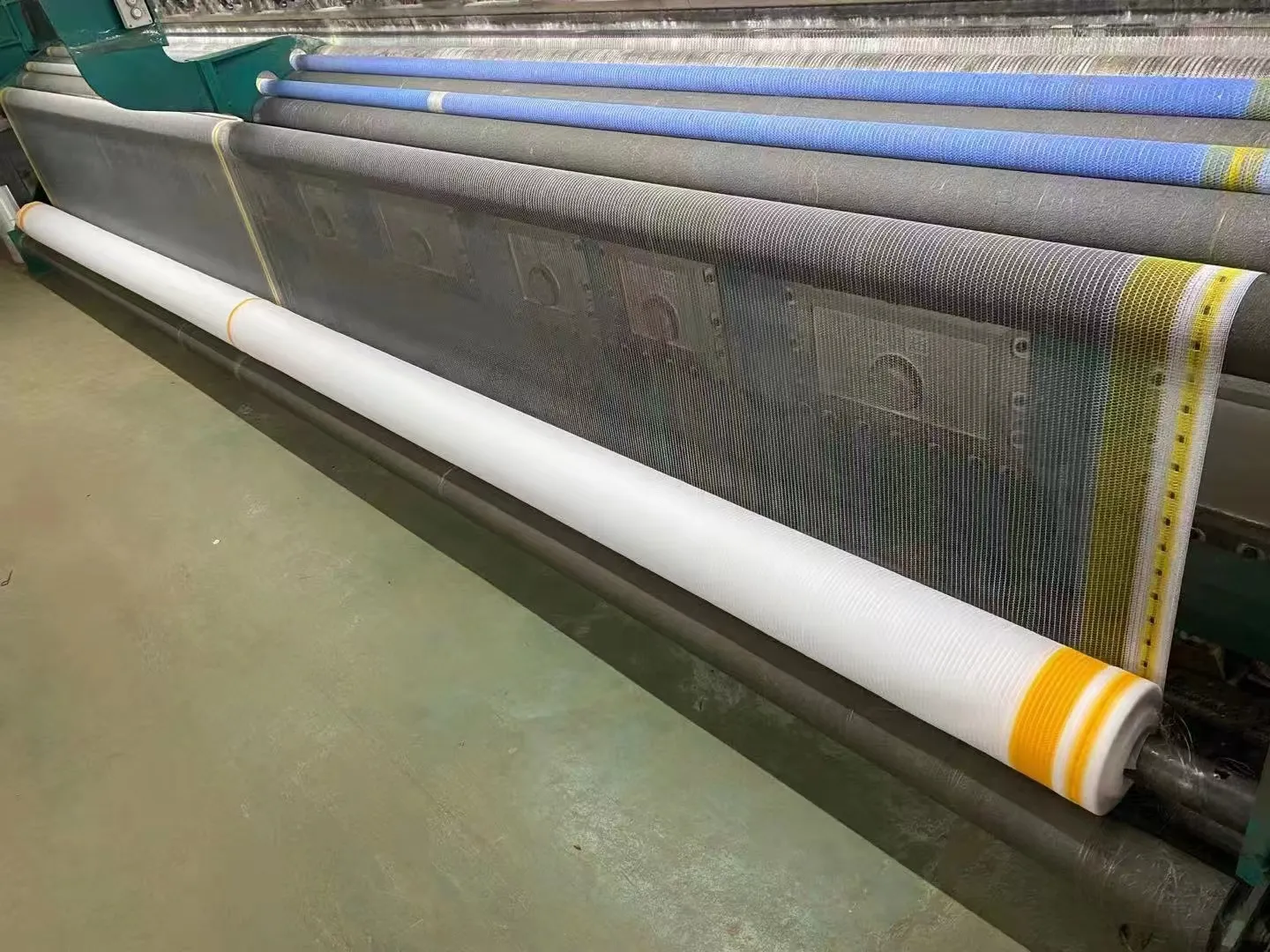

High-Speed Wire Mesh Manufacturing Machines Automated & Durable

- Industry Overview & Demand Drivers

- Technological Breakthroughs in Production Systems

- Performance Comparison: Leading Manufacturers (2023 Data)

- Custom Engineering for Specialized Applications

- Success Stories Across Industries

- Sustainability & Operational Efficiency

- Future of Wire Mesh Manufacturing Technology

(wire mesh manufacturing machine)

Wire Mesh Manufacturing Machines: Powering Industrial Fabrication

The global wire mesh production equipment market reached $2.8B in 2023, driven by 7.2% annual growth in construction and infrastructure projects. Modern weld mesh manufacturing machines now achieve production speeds exceeding 120 meters/minute, a 40% efficiency gain since 2018.

Advanced Engineering Redefining Production

Fourth-generation machines integrate:

- AI-assisted tension control (±0.05N precision)

- Multi-axis welding heads (1200 spots/minute)

- Energy recovery systems reducing power consumption by 18%

Real-time thickness monitoring (50μm resolution) prevents material waste, achieving 99.3% first-pass yield in ISO-certified facilities.

Manufacturer Performance Benchmarking

| Manufacturer | Speed (m/hr) | Wire Range (mm) | Automation Level | MTBF | Price Range |

|---|---|---|---|---|---|

| MagnaMesh Pro 450 | 6,200 | 1.0-8.0 | Level 4 | 1,850h | $420K-$580K |

| SteelWeave X9 | 5,800 | 0.8-6.5 | Level 3 | 1,600h | $380K-$520K |

| EcoFab Titan | 7,100 | 1.2-12.0 | Level 4+ | 2,200h | $680K-$920K |

Mean Time Between Failures

Application-Specific Configuration Options

Modular designs enable rapid adaptation:

- High-frequency welders for aerospace meshes (0.3-1.2mm wires)

- Galvanizing inline modules (15μm coating precision)

- Dual-wire feeding systems for composite materials

Custom tooling changes now require 23 minutes vs. traditional 4-hour setups.

Global Deployment Case Studies

Automotive: German Tier-1 supplier achieved 14-second cycle times for exhaust system filters

Construction: UAE plant produces 28-ton daily output of seismic reinforcement grids

Agriculture: Brazilian manufacturer reduced material waste by 31% through adaptive cutting systems

Eco-Conscious Production Innovations

Regenerative drives recover 92% of braking energy, while closed-loop lubrication systems achieve 99% fluid reuse. ISO 50001-certified models demonstrate 19% lower carbon footprint per ton produced versus 2020 benchmarks.

Wire Mesh Manufacturing Machines: Next-Gen Developments

Emerging technologies include:

- Machine learning-powered predictive maintenance (85% accuracy in failure anticipation)

- Hybrid resistance/laser welding systems (0.02mm positional accuracy)

- Blockchain-enabled material tracing from raw wire to final product

Current R&D focuses on achieving zero-downtime production through redundant systems and AI-optimized maintenance schedules.

(wire mesh manufacturing machine)

FAQS on wire mesh manufacturing machine

Q: What are the main types of wire mesh manufacturing machines?

A: The primary types include welded mesh machines, woven mesh machines, and expanded metal mesh machines. Each specializes in different mesh patterns and applications. Welded mesh machines are ideal for structural uses like fencing.

Q: How does a weld mesh manufacturing machine work?

A: It uses electric resistance welding to fuse intersecting metal wires into a grid pattern. Automated systems feed, align, and weld wires for consistent output. This process ensures high-speed production of durable mesh panels.

Q: What factors determine the choice of a mesh manufacturing machine?

A: Key factors include wire diameter, mesh size requirements, production volume, and end-use applications. Automation level and machine durability also influence selection. Customization options for patterns or coatings may also matter.

Q: Can wire mesh machines produce custom-sized mesh panels?

A: Yes, most modern machines allow adjustable settings for wire spacing and panel dimensions. Advanced models use CNC controls for precise customization. Custom tooling can also create unique mesh designs.

Q: What industries rely on weld mesh manufacturing machines?

A: Major industries include construction (reinforcement mesh), agriculture (animal fencing), and automotive (grilles). Industrial filtration and mining sectors also use these machines. The versatility suits both lightweight and heavy-duty applications.

-

Stainless Steel Mesh SolutionsNewsMay.06,2025

-

Protecting Your Farm with Smart SolutionsNewsMay.06,2025

-

Practical Mesh Solutions for Your Home and GardenNewsMay.06,2025

-

Nylon Mesh SolutionsNewsMay.06,2025

-

Fish Breeding Nets for AquariumsNewsMay.06,2025

-

Essential Mesh Solutions for ConstructionNewsMay.06,2025