Anping County Yongji Metal Products Co., Ltd.

Industry leader in filtration technology since 1997 with ISO 9001 certified production systems. Specializing in high-performance filtration solutions across multiple industries. Contact our engineering team for technical consultation:

+86 18032839562

+86 15297601727

admin@yjwiremesh.com

Innovative Filtration Solutions

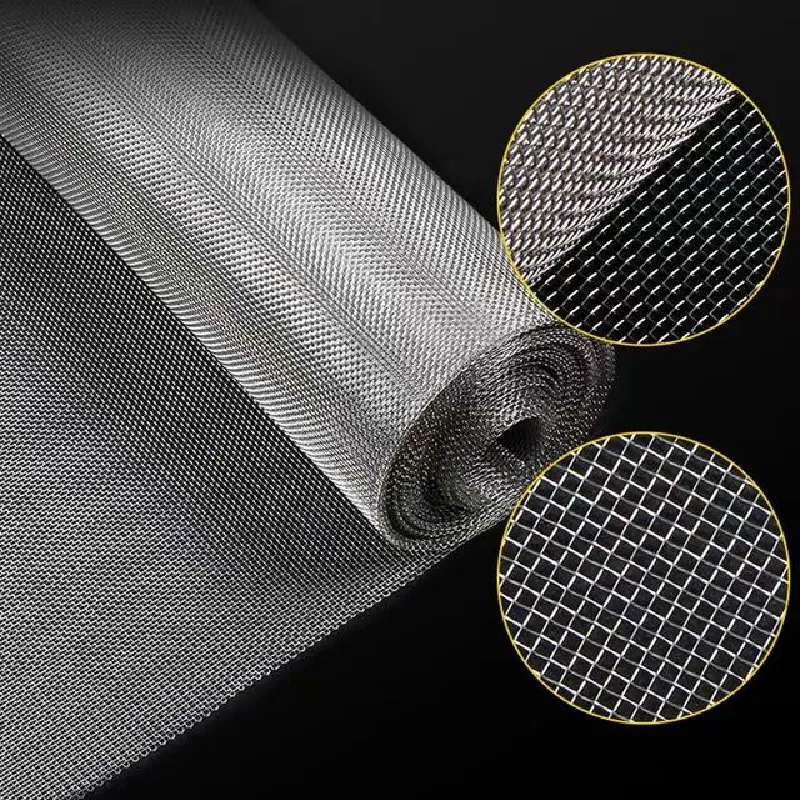

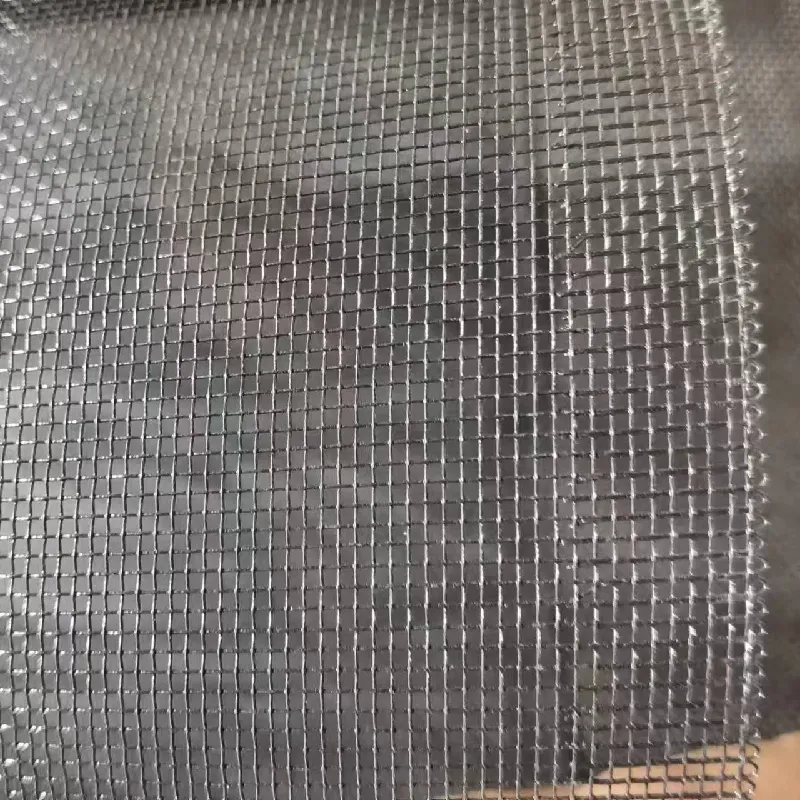

Process And Uses Of Stainless Steel Woven Mesh Widely used in various filter elements for: liquid, gas, and solid filtration, industrial and construction gravel screening, mechanical accessories safety protection, and other applications.

View Product DetailsTechnical Specifications

| Parameter | Range | Standard | Application |

|---|---|---|---|

| Material | SS304, SS316, SS316L | ASTM A480 | Chemical processing |

| Wire Diameter | 0.025mm - 5mm | ISO 4783 | Precision filtration |

| Mesh Count | 1 - 635 mesh/inch | ISO 9044 | Particle separation |

| Aperture Size | 0.02mm - 10mm | ASTM E11 | Sieve classification |

| Tensile Strength | 600-1200 MPa | ISO 6892 | Structural reinforcement |

| Temperature Resistance | -270°C to 760°C | ASTM A276 | High-temperature environments |

Material Performance Comparison

Stainless Steel Woven Mesh Applications

Industry Applications

From aerospace to food processing, Stainless Steel Woven Mesh solves complex filtration challenges:

Oil & Gas Processing

High-pressure filtration systems for refining operations with SS316 mesh solutions that withstand corrosive environments.

Pharmaceutical Manufacturing

GMP-compliant sterile filtration for critical processes requiring 5-micron precision separation.

Water Treatment Plants

Municipal water purification systems using multi-layer graded mesh designs for long-term durability.

Architectural Design

Decorative façades and safety barriers incorporating tensioned mesh panels with customized aesthetic patterns.

Technical FAQ

Industry References & Technical Citations

- International Wire Mesh Institute. (2023). Standards for Industrial Filtration Media. https://www.iwmi.org/filtration-standards

- Materials Performance Journal. (2022). Corrosion Resistance in Woven Metal Alloys. https://www.materialperformance.com/corrosion-research

- Filtration + Separation Technology. (2023). Advances in Aerospace Filtration. https://www.filtsep.com/aerospace-tech

- American Society of Mechanical Engineers. (2024). Structural Applications of Metal Mesh. https://www.asme.org/mesh-construction