-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Guidelines for Selecting and Utilizing Gabion Wire Material Specifications in Construction Projects

Gabion Wire Specification An Overview

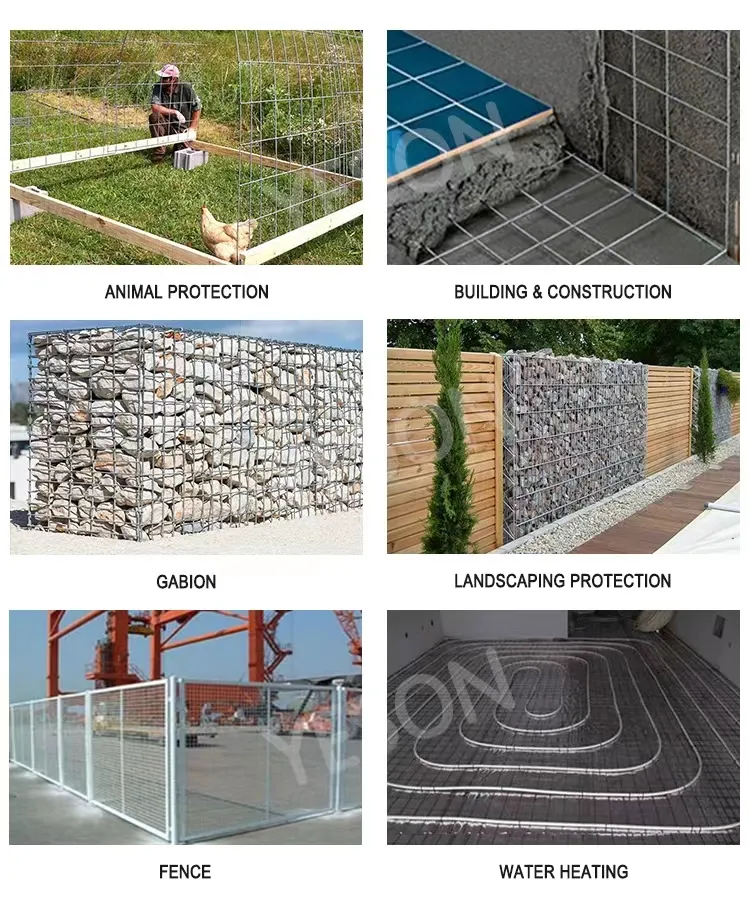

Gabions, often referred to as wire mesh containers filled with rock, soil, or other materials, have become increasingly popular in various applications, including erosion control, landscaping, and civil engineering. A critical aspect of gabion construction is the specification of the wire used to create these structural containers. This article will explore the key components of gabion wire specifications, ensuring the durability and effectiveness of gabion systems.

Material Composition

The most commonly used material for gabion wire is galvanized steel due to its excellent anti-corrosive properties. The galvanization process involves coating the steel wire with a layer of zinc, which protects it from rust and degradation when exposed to moisture and environmental elements. In regions with extreme weather conditions, or where the soil is highly acidic, wire with additional coatings, such as PVC (polyvinyl chloride), is also utilized to enhance the lifespan of the gabion structure.

Wire Diameter

The diameter of the wire is a crucial factor that influences the strength and stability of the gabion units. Typical wire diameters range from 2.0 mm to 4.0 mm, with thicker wires offering greater strength and durability. However, the choice of wire diameter should also consider the intended use of the gabion. For structures subjected to significant loads or severe environmental conditions, opting for a thicker wire may be prudent.

Tensile Strength

Tensile strength measures the maximum amount of tensile (pulling) stress a material can withstand before failure. Gabion wire should have a tensile strength of at least 450 MPa. The choice of wire with adequate tensile strength is vital, especially for applications like retaining walls or along riverbanks where resistance to shear forces is essential.

gabion wire specification

Welded vs

. Woven Wire MeshGabion structures can be constructed using either welded or woven wire mesh. Welded wire mesh is made by electrically welding intersecting wires, creating a rigid framework. This type offers enhanced strength and less deformation, making it suitable for permanent structures. Conversely, woven wire mesh, which consists of interlaced wires, provides flexibility and is often favored for temporary or flexible applications. The choice between the two types depends on the specific requirements of the engineering project.

Corrosion Resistance

As mentioned earlier, corrosion resistance is paramount in gabion wire specifications. Besides galvanization, the wire should undergo tests to evaluate its resistance to corrosion over time. The zinc coating weight is typically specified in grams per square meter (g/m²), with higher values indicating better corrosion resistance. A minimum of 275 g/m² is often recommended for effective long-term performance in harsh environments.

Compliance Standards

When selecting gabion wire, it is essential to ensure compliance with relevant standards and certifications. Organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide guidelines on wire specifications for gabion applications. Adhering to these standards guarantees that the wire used is reliable, tested, and suitable for its intended use.

Conclusion

In summary, the specification of gabion wire is a critical factor determining the success and longevity of gabion structures. By considering aspects such as material composition, wire diameter, tensile strength, type of mesh, and corrosion resistance, engineers and designers can select the most appropriate wire for their specific applications. A thorough understanding of gabion wire specifications not only enhances the structural integrity of the installations but also ensures that they perform effectively under various environmental conditions. Proper selection and adherence to standards can lead to sustainable and resilient solutions in landscaping and civil engineering projects.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025