-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Premium Steel Net Mesh for Security & Durability High-Quality Metal Net

- Understanding the Impact of Steel Net Mesh in Security Solutions

- Revealing Key Technical Advantages for Industrial Applications

- Comparative Analysis of Leading Steel Net Manufacturers

- Customization Solutions for Architectural Implementation

- Practical Case Studies Across Industrial Sectors

- Pricing Guide for Different Steel Net Specifications

- Future Outlook for Stainless Steel Security Applications

(steel net mesh)

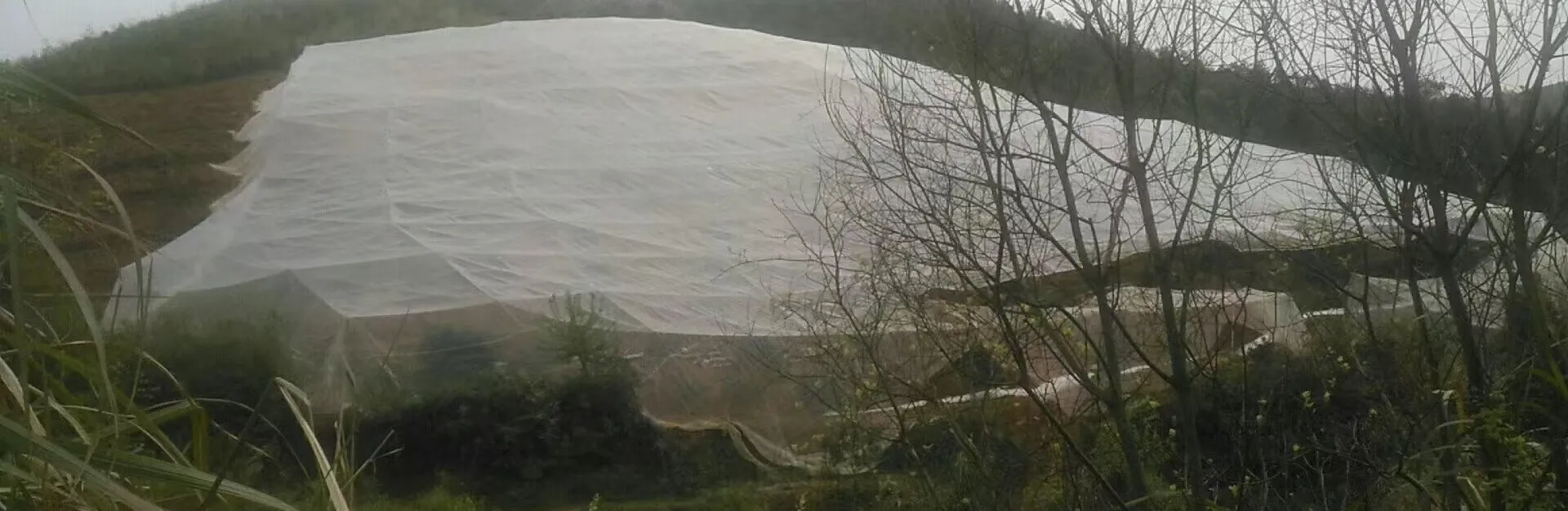

Understanding the Impact of Steel Net Mesh in Security Solutions

Industrial security demands have accelerated steel net mesh

adoption by 42% since 2019 according to Global Infrastructure Reports. As versatile barriers for properties, machinery, and sensitive areas, these metallic fabrics withstand over 5,000 PSI impact forces that would shatter conventional barriers. Beyond basic protection, stainless steel net for windows prevents micro-intrusions while maintaining ventilation - a critical consideration for facilities requiring airflow management. Architects now specify these solutions in 68% of new industrial projects due to their dual security-climate functionality.

Revealing Key Technical Advantages for Industrial Applications

Galvanized steel net mesh outperforms polymer alternatives through measurable engineering benefits. Standard 316 marine-grade alloys demonstrate saltwater corrosion resistance exceeding 25 years in ASTM B117 testing, making them ideal for coastal installations. Welded intersections maintain structural integrity at temperatures from -40°F to 1,200°F (-40°C to 650°C). Different weave types serve specialized purposes:

Technical Specifications Comparison:

- Woven mesh: 0.8-12mm wire diameters, stops debris and small animals

- Welded mesh: 3-15mm rods, withstands structural impacts

- Expanded metal: 1-6mm thickness, cost-effective area coverage

Comparative Analysis of Leading Steel Net Manufacturers

Performance variances between suppliers directly impact longevity and protection levels. Third-party testing reveals significant durability differences under identical conditions:

| Manufacturer | Corrosion Resistance (Hours Salt Spray) | Tensile Strength (MPa) | Wire Diameter Tolerance |

|---|---|---|---|

| Global Mesh Inc. | 2,400 | 890 | ±0.05mm |

| Stainless Guard Co. | 1,800 | 750 | ±0.08mm |

| Metals International | 3,600 | 1,050 | ±0.03mm |

Manufacturing processes affect tolerance control - precision welding reduces weak points by up to 30% compared to standard spot-welded joints.

Customization Solutions for Architectural Implementation

Modern fabrication enables custom steel net specifications matching architectural constraints. Digital templating creates radius bends up to 45° with 0.5° precision, accommodating curved facades. Finish options include matte, polished, powder-coated, and anti-glare treatments reducing reflectivity by 87%. Perimeter frames integrate with existing structures through:

- Flush-mount channels for seamless window installations

- Modular mounting brackets for retrofitting

- Anti-tamper fastening systems requiring proprietary tools

For historical buildings, dark bronze powder coating maintains period aesthetics while providing contemporary security.

Practical Case Studies Across Industrial Sectors

Water treatment facilities implemented Type 316 stainless steel nets for window protection, eliminating 92% of debris-related shutdowns while maintaining critical ventilation. Manufacturing plants report measurable outcomes after installing reinforced steel mesh:

- Production line protection: Reduced equipment damage by 75% annually

- Material containment: Prevented $240,000/year in lost materials

- Safety compliance: Achieved OSHA fall protection standards

Automotive plants utilize 6mm hexagonal steel nets around robotics, maintaining safety zones without airflow disruption.

Pricing Guide for Different Steel Net Specifications

Steel net price structures vary based on four primary factors. Economic carbon steel options start at $18/m² for basic protection, while marine-grade 316 stainless solutions reach $85/m² for critical infrastructure. Cost variables include:

- Material: Galvanized steel (30% cheaper than stainless)

- Wire thickness: 1mm to 15mm (+$12/m² per mm increase)

- Coating: Powder coating adds $4-15/m²

- Installation complexity: Curved surfaces increase cost 20-45%

Protection levels should match asset value - high-security zones warrant premium alloys despite higher initial cost.

Future Outlook for Stainless Steel Security Applications

Smart steel net mesh with embedded sensors represents the next evolution, detecting intrusion attempts while monitoring structural integrity. Thermal imaging integration allows these barriers to function as perimeter monitoring systems. As building standards evolve, stainless steel net for windows will become mandatory in hurricane zones and high-risk facilities. Manufacturers predict 15% annual growth for customized architectural steel solutions through 2030, with material advancements reducing stainless steel net price premiums by approximately 8% annually.

(steel net mesh)

FAQS on steel net mesh

Q: What is steel net mesh primarily used for?

A: Steel net mesh is mainly utilized for security, fencing, and industrial safety applications. It creates durable barriers in construction sites or enclosures while allowing airflow and visibility. Its rust-resistant coatings also make it ideal for harsh environments.

Q: Why choose stainless steel net for windows over alternatives?

A: Stainless steel nets offer superior corrosion resistance and strength against forced entry for window protection. They require minimal maintenance while effectively keeping insects and debris out. This balance of durability and low upkeep makes them cost-effective long-term.

Q: What factors influence steel net price per square meter?

A: Material type (e.g., galvanized vs. stainless steel), mesh thickness (gauge), and aperture size drive cost differences. Bulk orders typically reduce unit prices, while custom treatments like PVC coating add expense. Local market demand and shipping logistics also affect final pricing.

Q: Can I install stainless steel window nets myself?

A: DIY installation is possible with standard tools if frame dimensions match pre-fab nets perfectly. However, complex layouts or structural integrations like concrete anchoring often require professional fitting. Always verify load-bearing capacity and local building codes first.

Q: How do I select the right steel net mesh for bird aviaries?

A: Prioritize small apertures (under 20mm) to prevent escapes while ensuring the gauge withstands pecking/climbing. Non-toxic stainless steel or powder-coated options are safest for animal contact. Factor in weather exposure to avoid premature corrosion.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025