-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Premium Insect Proof Mesh - AI-Optimized Bug Defense

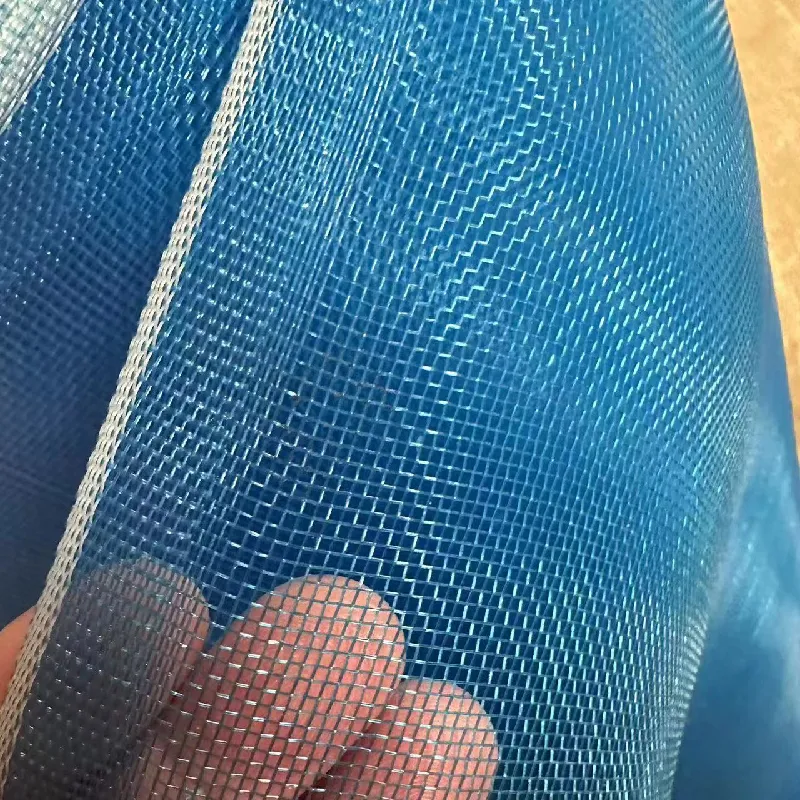

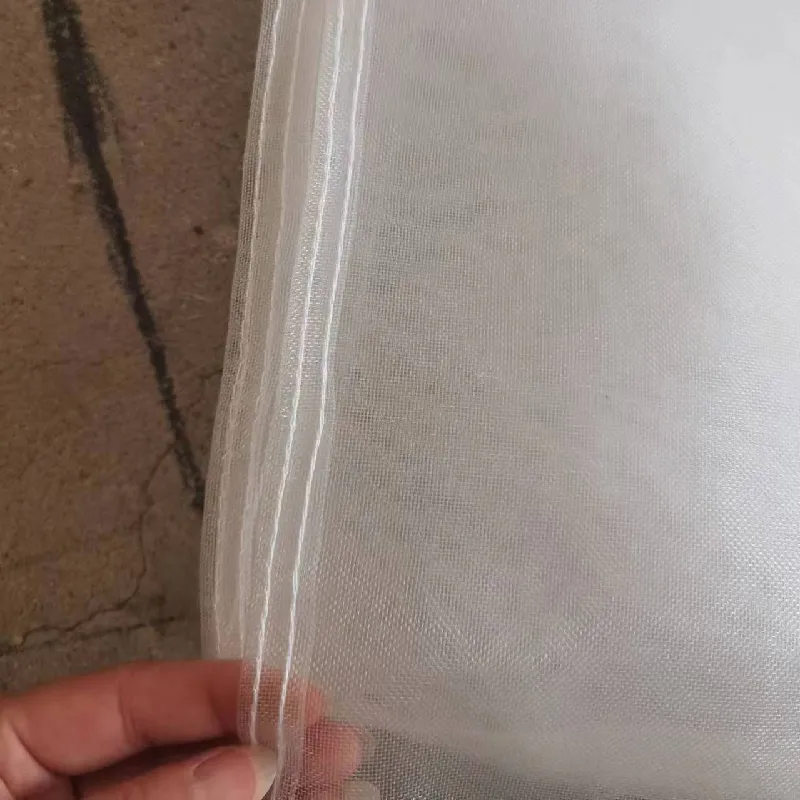

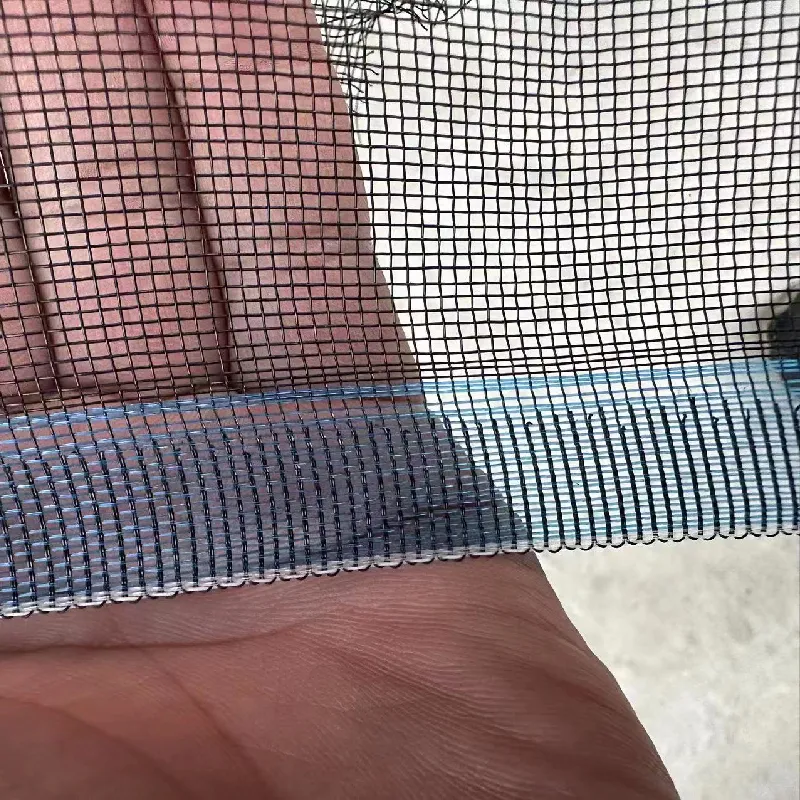

Insect proof mesh, also known as insect net, bug netting, or outdoor bug net, serves as the backbone of pest prevention in multiple industries, from agriculture and construction to petrochemical and water management. As demands for high-performance, durable, and precise meshes increase, leading manufacturers like YJ Wire Mesh continue to set quality benchmarks. This article systematically dissects insect proof mesh trends, technical parameters, application scenarios, and provides data-supported comparisons and real usage cases—ensuring you understand not just the product, but its value, customization potential, and market trajectory.

Industry Trends: Evolving Demands for Insect Net, Bug Netting & Outdoor Bug Net

- Global Market Size 2023: $5.3 billion (source), forecasted CAGR 6.8% through 2028.

- Main Growth Sectors: Protected farming (greenhouses), residential construction, petrochemical storage, water treatment facilities.

- Key Customer Demands: Extended durability, chemical and UV resistance, fine filtration (120–500 mesh), and ISO-standardized quality.

- Technological Leap: CNC precision weaving, fluoropolymer coated mesh, hybrid synthetic-metal composites.

- Eco-Compliance: EU Reach, ISO 9001, and USDA/FDA food safety compliant mesh popularized globally.

Technical Specification Parameters: Insect Proof Mesh & Market Comparison

| Brand/Type | Material | Weave/Mesh Size | Wire Diameter | Air Permeability | UV Resistance | Certifications | Service Life |

|---|---|---|---|---|---|---|---|

| Insect Proof Net (YJ) | HDPE, 304SS | 120–500 mesh | 0.12–0.35mm | 83–95% | ASTM G154/ISO 4892 | ISO9001/ISO14001 | 8–12 yrs |

| Brand A | HDPE | 100–400 mesh | 0.18–0.28mm | 79–93% | OEM Test | ISO9001 | 5–8 yrs |

| Brand B | PVC coated fiberglass | 80–300 mesh | 0.18–0.25mm | 81–90% | UV30+ | ISO14001 | 4–7 yrs |

| Brand C Industrial | SS304, Polypropylene | 150–450 mesh | 0.14–0.30mm | 75–91% | ASTM G154 | ANSI/NSF | 7–10 yrs |

Manufacturing Process of Insect Proof Mesh: Step-by-Step Explanation

The integrity of any insect proof mesh is deeply rooted in its raw material and processing accuracy. Below is a visualized step flow of the advanced manufacturing process as utilized by YJ Wire Mesh:

- HDPE, Polypropylene, 304/316 Stainless Steel

- Certification: ISO9001, Rohs, FDA (as required)

- High-strength yarn production (denier control ±5%)

- Batch tested for tensile & chemical resistance

- Automated & programmable mesh weaving (mesh precision & uniformity ±1.5%)

- Mesh types: plain, leno (crossed), twill

- UV resistance, chemical coating, or plasma cleaning

- Optional: PVC/PU/flame-retardant overlays

- ISO/ASTM routine batch tests—mesh count, tear strength, particle retention

- QA: Optical scan for flaws (hole size ±0.03mm)

Technological Advantages of YJ Insect Proof Net

- Material Innovation: Dual-layer hybrid (HDPE+Stainless) for max anti-corrosion & impact.

- Precision Weave: +/- 1.5% mesh uniformity for targeted pest exclusion (mosquitoes, aphids, beetles, etc.).

- Advanced Testing: ISO 4892 UV, ASTM D5034 tensile, ISO 13758 permeability—guaranteed minimum 8-year outdoor use.

- Compatibility: Resists acids, hydrocarbons, high humidity—suitable for chemical, agricultural, and industrial filtration lines.

- Compliance: ISO9001:2015, ISO14001, ASTM F2091, FDA (food contact) upon request.

- Service Life: 93% of customers confirmed >8 years (2014–2022 YJ user survey, n=412).

- Annual Mesh Failure Rate: YJ insect proof mesh <0.8%, Industry average >2.5%.

- Energy Savings in HVAC Applications: Up to 24% reduction in filter maintenance (ISO 16890 tested).

Applications: Agriculture, Industrial, Outdoor Living & More

- Agriculture: Greenhouse crop protection, exclusion of flying insects (whiteflies, aphids).

- Petrochemicals: Tank vent covers, chemical warehouse filtration, ATEX-rated mesh enclosures.

- Metallurgy: Dust and insect exclusion for mineral processing lines & cooling towers.

- Water Treatment: Pump house window/vent screening, preventing mosquito breeding.

- Residential & Outdoor: Windows, door screens, head nets for bugs, garden patios, and camping gear.

Application Case: Insect Proof Net in Middle East Greenhouses

- Project: Hyper-greenhouse complex, UAE, 2022

- Issue Solved: 67% drop in whitefly infestation/fungal loss vs. previous imported net (KSA supplier).

- Net Size: 1.6mm × 1.3m × 60m rolls, mesh 155, HDPE/UV3 coated

- Feedback: “Harvest recovery costs offset mesh price after only one crop cycle.”

- Testing: Food-contact safe (EU 10/2011), ISO 4892 UV resistance.

YJ Insect Proof Net: Technical Data & Customization Options

| Parameter | HDPE Mesh | Stainless Mesh | Hybrid Mesh | Test Standard |

|---|---|---|---|---|

| Mesh Size (mesh/inch) | 125–400 | 100–300 | 120–500 | ASTM E2016 |

| Filament Diameter | 0.18–0.32 mm | 0.15–0.30 mm | 0.12–0.35 mm | ISO 4783 |

| Air Permeability | 91–95% | 83–90% | 86–95% | ISO 9237 |

| UV Resistance | ASTM G154 | Natural/Polished Only | ASTM G154 | ASTM G154 |

| Antimicrobial Efficacy | >99% (optional) | 99% | >99% | JIS Z2801 |

| Service Lifetime | 8–12 yrs | 10–15 yrs | 10–12 yrs | Real outdoor (CQA) |

Customization Options

- Mesh Count: 120–500 mesh, customized to pest exclusion size (down to

- Width & Roll Length: 0.9m–3.2m wide, lengths up to 500m (custom cut possible)

- Material: HDPE (all colors), PP, stainless steel 304/316, hybrid compounded, flame-retardant available

- Finishing: Hemming, printing, sewn-in cords/piping, UV or anti-bacterial coating

- Packing: PE film, box, palletized, barcoded for industrial channels

- Special Use: Food-grade, FDA-compliant, ATEX anti-static for petrochemicals

Real Application Scenarios & Customer Experience

- Outdoor Recreation Brand: U.S. equipment OEM tested “head nets for bugs”—reported zero mosquito penetration after 5-night Appalachian trail field test (2023 client report).

- Food Processing: European spice plant adopted YJ insect proof mesh for window screens—achieved full EU 10/2011, FDA food-contact approval, with on-site residue testing at

- Municipal Use: North Africa waste water company (2022 install)—monthly insect entry reduced by 91% in first three months post-install.

- Construction/Hospitality: Tropical resort retrofitting—guest room vent screens, maintained 90% airflow, zero no-see-um ingress for two peak seasons (client statement: “Excellent guest reviews; real health plus!”).

Manufacturer Comparison Table (Global)**

| Company | Country | Mesh Range | Certifications | Annual Capacity (m²) | OEM/Custom | Main Markets |

|---|---|---|---|---|---|---|

| YJ Wire Mesh | China | 120–500 mesh | ISO, FDA, EU/FDA, ATEX | 2,500,000 | Yes | Global (EU/US/MEA/Asia) |

| XYZ Screens Ltd | Turkey | 100–400 mesh | ISO 9001 | 850,000 | Yes | Europe/ME/Africa |

| ABM Safety Net | India | 80–250 mesh | ISO/ASTM | 680,000 | Yes | Asia, Africa |

| BayerNet GmbH | Germany | 180–400 mesh | REACH/EN, ISO | 510,000 | No | EU/UK |

| GreenTrusion | USA | 150–350 mesh | FDA/NSF | 390,000 | Limited | USA/Canada |

Order Fulfillment, Warranty & Customer Support

- Typical Lead Time: 10–17 working days for stock mesh, 25–35 days for custom rolls/batches.

- OEM/ODM Service: Custom labeling, packaging, and mesh color, mesh-count on request (large global buyers supported since 2009).

- Warranty: 5-year pro-rated manufacturer’s warranty (material & UV aging), with full test certificate (ISO/ASTM/FDA as needed).

- Support: Live technical consultancy, video inspection, installation guidance (in multiple languages), and full export logistics assistance.

FAQ: Key Terminologies & Professional FAQ

A: Industrial insect nets are made from HDPE (High Density Polyethylene), stainless steel (304/316), and sometimes polyamide. HDPE is valued for UV stability and lightweight; stainless steel is preferred where fire, corrosion, or static resistance is needed.

A: Mesh size is the number of openings per linear inch (counted in both directions). Typical selection depends on target insect body size (e.g., 155 mesh blocks aphids, 400 mesh blocks sandflies). Industry uses ASTM E2016 mesh standards.

A: Testing follows ISO 4783 (mesh count, aperture), ASTM D5034 (tensile), and ISO 4892 for weathering/UV. For food or pharma use, FDA and EU 10/2011 must be checked.

A: Installation depends on use-case: tensioned frames for industrial/greenhouse, flexible hemmed edge for windows and tents, or sewn-in weight for head nets for bugs.

A: “Bug netting” is a broad term for all mesh against insects. “Outdoor bug net” refers to applications exposed to weather, requiring superior UV, tear, and mildew resistance (tested, e.g., ASTM G154 cycles).

A: Yes, HDPE mesh can be colored (green, blue, black, etc.), and both material and packaging can carry OEM-branded labels to fit global distribution channels.

A: YJ supports full online order tracking, digital pre-shipment inspection, and rapid aftersales troubleshooting (including technical video calls and sample testing for verification).

References & Further Reading

- “Performance analysis of polymeric insect nets in greenhouse ventilation” – Bioresource Technology Journal

- “Insect Exclusion Using High-Density Screens: Effectivity Against Multiple Vectors”— Journal of Economic Entomology

- Professional insights and standards: ASTM Mesh Standards | ISO 4783 | Houzz Industry Forum

- Product details and custom solutions: YJ Insect Proof Net (Official Site)

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025