-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

spring steel wire mesh

Understanding Spring Steel Wire Mesh

Spring steel wire mesh is an essential material widely used in various industrial applications due to its remarkable properties, which include high tensile strength, excellent elasticity, and outstanding wear resistance. This specialized type of mesh is made from steel alloys that are specifically formulated to provide superior performance under stress and deformation, making it ideal for situations where durability and flexibility are crucial.

One of the defining characteristics of spring steel is its ability to return to its original shape after being subjected to significant loads. This quality is attributed to the specific composition of the steel, which often includes carbon and other alloying elements that enhance its mechanical properties. By treating the wire mesh through specific heat processes such as hardening and tempering, manufacturers can optimize its strength and elasticity, resulting in a product that can withstand repeated bending and dynamic loading.

Spring steel wire mesh finds applications across various industries. In the automotive sector, it is commonly used for manufacturing suspension components, such as coil springs and shock absorbers, where resilience is paramount. The mesh design allows for effective fluid flow, which is essential for heat dissipation and the efficient operation of automotive systems. Furthermore, its use in machinery, such as conveyor belts and screens, enhances functionality by providing strong yet flexible support structures.

spring steel wire mesh

Construction also benefits from spring steel wire mesh, where it is used in reinforced concrete applications

. The mesh provides additional tensile strength to the concrete, significantly enhancing its load-bearing capabilities. By integrating spring steel wire mesh into construction materials, builders can ensure greater longevity and structural integrity, thereby meeting the demands of modern infrastructure projects.Moreover, in the agricultural sector, this type of mesh serves vital roles in fencing and livestock enclosures, ensuring safety and security. Its resistance to corrosion also makes it suitable for outdoor applications, where exposure to various environmental conditions can lead to rust and degradation in standard materials.

The manufacturing process of spring steel wire mesh involves precise machinery and quality control measures to ensure consistency and reliability in the final product. As industries continue to evolve, the demand for high-performance materials like spring steel wire mesh is expected to increase. This growth will be driven by ongoing advancements in technology and engineering, focused on enhancing efficiency and sustainability in industrial applications.

In conclusion, spring steel wire mesh is a versatile and indispensable material that demonstrates the perfect balance between strength and flexibility. Its unique properties enable it to perform effectively in demanding environments across various sectors, from automotive and construction to agriculture. As industries strive for innovation and better performance, the relevance of spring steel wire mesh will undoubtedly continue to grow, catering to the ever-changing needs of modern applications.

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

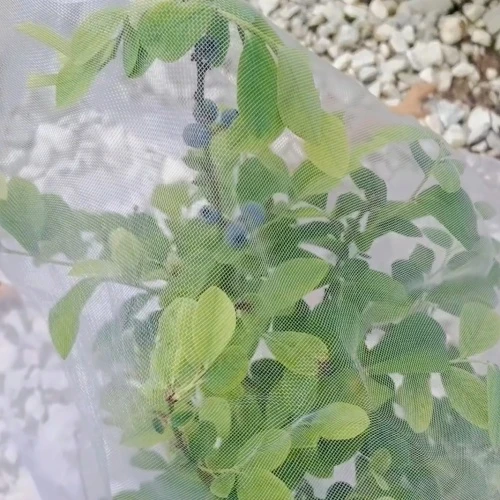

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025