-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Welding Mesh Pricing and Market Trends for 2023

The Price Dynamics of Welding Mesh A Comprehensive Overview

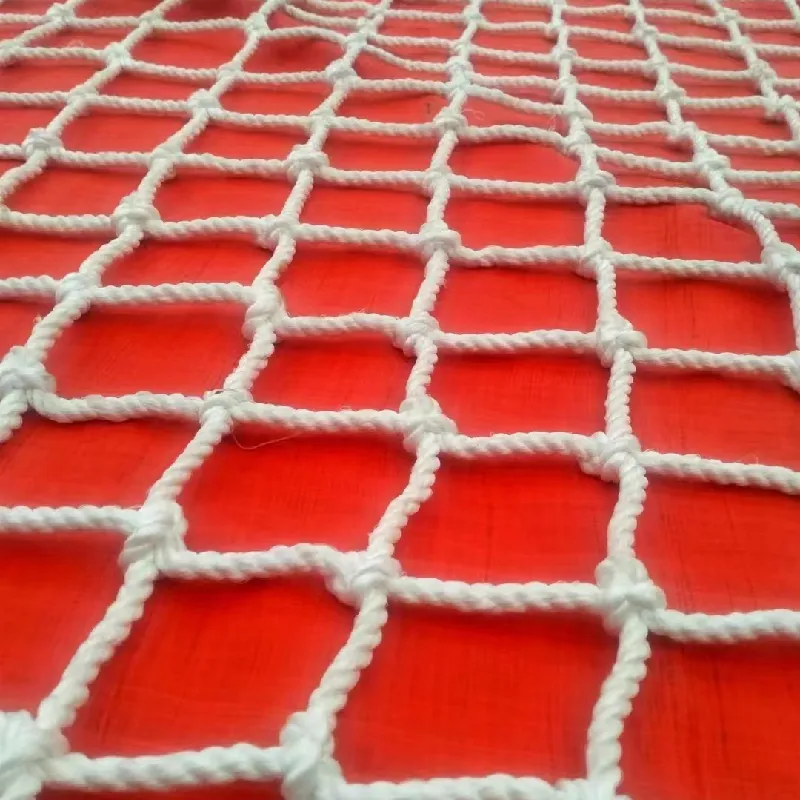

Welding mesh, also known as welded wire mesh or welded wire fabric, is an essential material used in various construction and manufacturing applications. Its versatility and structural integrity make it a popular choice for reinforcing concrete, creating enclosures, and crafting various products. Understanding the pricing dynamics of welding mesh is crucial for builders, contractors, and DIY enthusiasts alike.

The price of welding mesh can fluctuate based on several factors. One primary influence is the type of material used in its fabrication, typically wire made from steel or stainless steel. Galvanized steel welding mesh tends to be the most common due to its balance of strength and corrosion resistance, while stainless steel options are preferred in environments where rust is a significant concern. The price for stainless steel mesh often surpasses that of its galvanized counterpart, reflecting its superior durability.

In addition to material choice, the dimensions and specifications of the welding mesh greatly affect pricing. The thickness of the wire, the grid pattern, and the overall size of the panels are critical factors. Typically, thicker and larger panels command higher prices due to the increased material costs and manufacturing complexity. Custom-sized or specially designed welding mesh, tailored for specific projects, can also add to the expense.

welding mesh price

Another crucial factor impacting welding mesh prices is market demand and supply conditions. Economic fluctuations, construction industry trends, and seasonal demands often create price volatility. For instance, during peak construction seasons, the demand for welding mesh may rise, leading to increased prices. Conversely, during economic downturns, prices may decrease as demand wanes.

International trade policies and tariffs can also influence welding mesh prices. Steel is a globally traded commodity, and changes in trade regulations or tariffs imposed on steel imports can result in significant price variations across different markets. For instance, countries that heavily rely on imported steel may experience higher prices if trade barriers are introduced.

Additionally, production costs, including labor, energy, and transportation expenses, contribute to the final pricing of welding mesh. Manufacturers may pass on these costs to consumers, particularly if they face increased overheads.

In summary, the price of welding mesh is influenced by multiple factors, including material type, product specifications, market demand, international trade policies, and production costs. For buyers, it is essential to monitor these factors and shop around for competitive prices. Purchasing in bulk or establishing long-term contracts with suppliers can also help mitigate costs. Ultimately, understanding the pricing dynamics allows construction professionals to make informed decisions, ensuring the sustainability and success of their projects.

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025