-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Steel Mesh for Reinforcement in Construction Applications and Structural Strengthening Solutions

The Significance of Steel Fabric Reinforcement Mesh in Modern Construction

In the realm of construction, the integrity and strength of structures are paramount. One of the critical materials that contribute to this integrity is the steel fabric reinforcement mesh. This essential component plays a vital role in enhancing the structural performance of concrete elements, making it a staple in various construction projects.

Steel fabric reinforcement mesh, often referred to simply as reinforcement mesh or welded wire mesh, consists of a grid of steel wires that are welded together at intersections. This mesh is typically made from high-strength steel, which provides the necessary tensile strength and durability required for construction applications. The mesh is available in various sizes and configurations, catering to different structural requirements and standards.

The Role of Reinforcement Mesh

Concrete, while excellent in compression, is inherently weak in tension. This weakness can lead to cracks and failure under load if not properly reinforced. The introduction of steel fabric reinforcement mesh addresses this issue by providing additional tensile strength. When embedded within concrete, the mesh helps to distribute loads evenly, reducing the likelihood of structural failure.

One of the primary advantages of using steel fabric reinforcement mesh is its ability to enhance the ductility of concrete structures. Ductility is crucial because it allows structures to deform without collapsing, providing warning signs before failure occurs. With the incorporation of reinforcement mesh, buildings and infrastructures can better withstand dynamic loads, such as those from wind or earthquakes, ultimately leading to safer designs.

Applications in Construction

steel fabric reinforcement mesh

The versatility of steel fabric reinforcement mesh makes it suitable for a wide range of applications. It is commonly used in the construction of slabs, pavements, walls, and precast concrete elements. For instance, in urban areas where concrete slabs form the foundation of buildings, the use of reinforcement mesh ensures that these slabs can effectively handle the weight and stress imposed by the structure above.

Additionally, the mesh is employed in road and bridge construction, where it enhances the durability and lifespan of the concrete surfaces. The ability to withstand repeated loading and environmental impacts makes it an ideal choice for enhancing infrastructure resilience.

Environmental and Economic Benefits

Using steel fabric reinforcement mesh can also yield environmental and economic benefits. The mesh facilitates the reduction of material usage compared to traditional reinforcement methods, as it can provide similar, if not superior, structural performance with less material. This efficiency can lead to lower costs in both materials and labor, significantly benefiting project budgets.

Moreover, the durability of structures reinforced with mesh translates into longer lifespans and reduced maintenance costs over time. This longevity not only conserves resources but also minimizes the environmental footprint associated with frequent repairs or replacements.

Conclusion

Steel fabric reinforcement mesh is an indispensable component in modern construction that enhances the strength, durability, and safety of concrete structures. Its ability to provide tensile strength, improve ductility, and reduce material usage makes it a preferred choice for engineers and architects alike. As the construction industry continues to evolve, the reliance on such efficient and effective reinforcement techniques will undoubtedly grow, ensuring that our built environment is more resilient, sustainable, and capable of withstanding the tests of time. By understanding the vital role of steel fabric reinforcement mesh, stakeholders can make informed decisions that will lead to better construction practices and safer structures for future generations.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

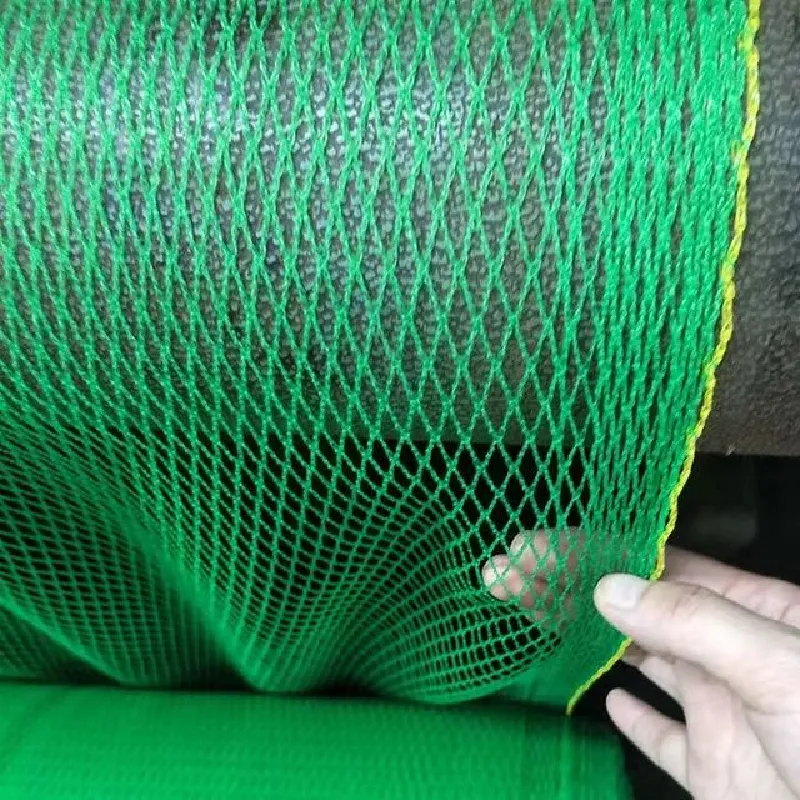

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025