-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

فروری . 05, 2025 05:10

Back to list

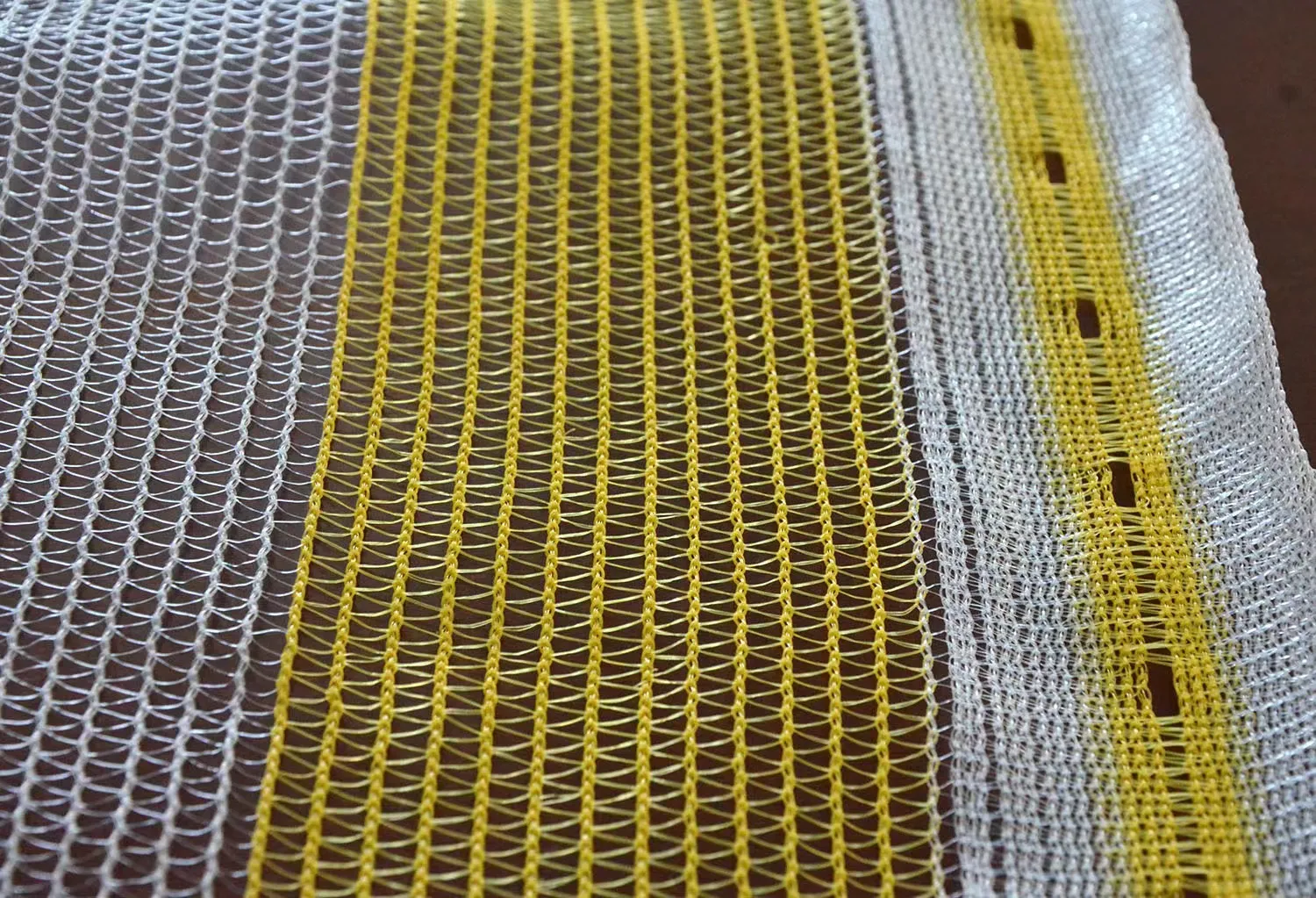

Welded Gabion Box 2x1x1 Hot Dipped Galvanized Welded Mesh Gabion

In the realm of construction and industrial projects, materials that combine efficiency with robustness are paramount. GI welded wire mesh, standing for Galvanized Iron welded wire mesh, is one such product that has steadily garnered the trust of industry experts. This article aims to explore the attributes, applications, and advantages of GI welded wire mesh, providing information that resonates with experience, expertise, authoritativeness, and trustworthiness—factors crucial for achieving a leading edge in SEO.

From an expertise perspective, manufacturing GI welded wire mesh requires a confluence of advanced technology and material science. The precision in welding and the quality of the galvanization process are pivotal in determining the final product's performance. Manufacturers who invest in state-of-the-art equipment and materials thereby enhance the mesh's reliability, providing a competitive advantage in the marketplace. Authoritativeness in the domain of GI welded wire mesh stems from long-standing field presence and a proven track record of performance in critical applications. Firms that produce these meshes often boast certifications from relevant authorities, ensuring compliance with international standards. As a consumer or project manager, selecting products from certified producers not only aligns with regulatory requirements but also guarantees specific performance metrics. For SEO-focused strategies, enhancing the trustworthiness of the content related to GI welded wire mesh means including testimonials from industry veterans, case studies of successful applications, and partnerships with credible organizations or institutions. Content should highlight real-world examples of how GI welded wire mesh has been pivotal in project success, emphasizing the tangible benefits experienced by end-users. In essence, GI welded wire mesh is more than just a construction material; it is a testament to engineering ingenuity. Its widespread adoption across industries is a testament to its intrinsic qualities and the trust it has built over years. Businesses seeking robust, reliable, and efficient solutions for their structural needs continue to turn to GI welded wire mesh, fostering a cycle of innovation and reliability. Thus, when considering GI welded wire mesh for your next project, remember that it's not just about selecting a material; it's about choosing a partner in construction longevity and success. Empowered with this knowledge, stakeholders can make informed decisions that not only meet but exceed expectations, standing the test of time in an ever-evolving industrial landscape.

From an expertise perspective, manufacturing GI welded wire mesh requires a confluence of advanced technology and material science. The precision in welding and the quality of the galvanization process are pivotal in determining the final product's performance. Manufacturers who invest in state-of-the-art equipment and materials thereby enhance the mesh's reliability, providing a competitive advantage in the marketplace. Authoritativeness in the domain of GI welded wire mesh stems from long-standing field presence and a proven track record of performance in critical applications. Firms that produce these meshes often boast certifications from relevant authorities, ensuring compliance with international standards. As a consumer or project manager, selecting products from certified producers not only aligns with regulatory requirements but also guarantees specific performance metrics. For SEO-focused strategies, enhancing the trustworthiness of the content related to GI welded wire mesh means including testimonials from industry veterans, case studies of successful applications, and partnerships with credible organizations or institutions. Content should highlight real-world examples of how GI welded wire mesh has been pivotal in project success, emphasizing the tangible benefits experienced by end-users. In essence, GI welded wire mesh is more than just a construction material; it is a testament to engineering ingenuity. Its widespread adoption across industries is a testament to its intrinsic qualities and the trust it has built over years. Businesses seeking robust, reliable, and efficient solutions for their structural needs continue to turn to GI welded wire mesh, fostering a cycle of innovation and reliability. Thus, when considering GI welded wire mesh for your next project, remember that it's not just about selecting a material; it's about choosing a partner in construction longevity and success. Empowered with this knowledge, stakeholders can make informed decisions that not only meet but exceed expectations, standing the test of time in an ever-evolving industrial landscape.

Latest news

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025