-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

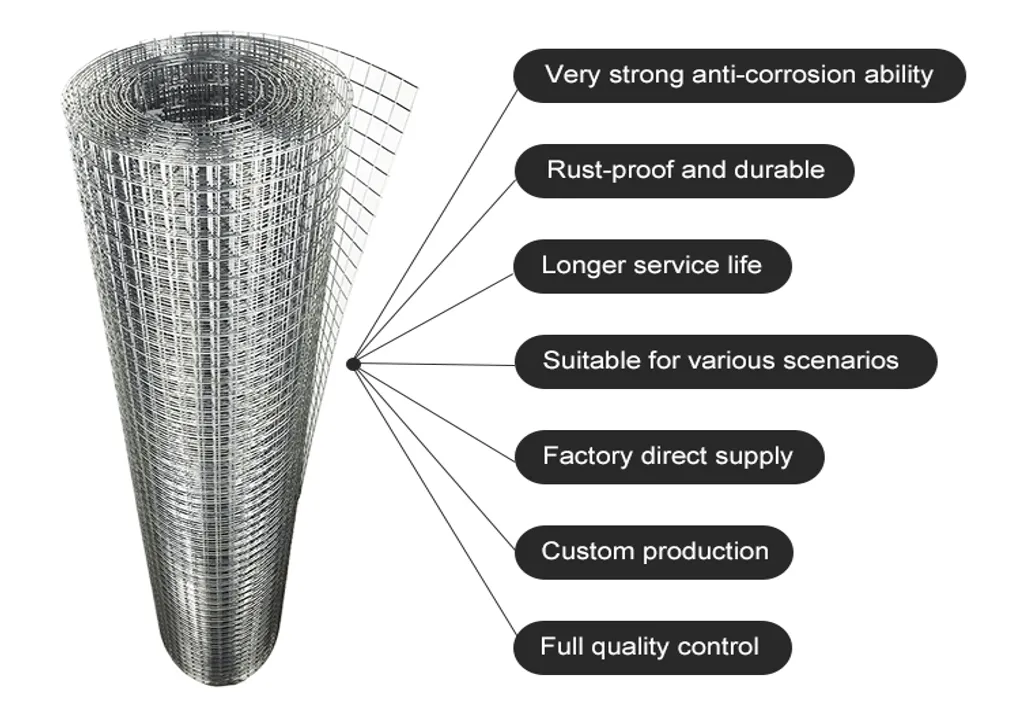

Galvanised Steel Mesh Durable & Corrosion-Resistant Wire Mesh

(steel galvanised mesh)

The Essential Guide to Steel Galvanised Mesh Solutions

Galvanised steel wire mesh represents a cornerstone in industrial and construction applications globally. This comprehensive overview examines critical aspects every professional should consider:

- Market impact and performance metrics

- Core technical advantages over alternatives

- Manufacturer capability analysis

- Custom fabrication parameters

- Specialist installation methodologies

- Documented application case studies

- Implementation best practices

Recent market analysis indicates a 7.8% annual growth in demand driven by infrastructure development, with the Asia-Pacific region accounting for 42% of global consumption according to the International Metalworking Federation.

Performance Advantages of Galvanised Coatings

Hot-dip galvanisation creates a metallurgical bond between zinc and steel that outperforms paint or epoxy coatings. Standard testing reveals:

- Corrosion resistance exceeding 35 years in atmospheric exposure

- Salt spray test results of 1,500+ hours before red rust formation

- Coating adhesion strength of 3,600 psi (ASTM D4541)

The zinc layer provides sacrificial protection where coatings become damaged. Independent tests confirm galvanised meshes withstand cyclic temperature variations from -40°C to 150°C without compromising structural integrity.

Manufacturer Capability Comparison

Leading suppliers differentiate through production technology and quality assurance:

| Manufacturer | Coating Thickness | Wire Gauge Range | ISO Certification | Lead Time |

|---|---|---|---|---|

| GlobalMesh Solutions | 70-85 microns | 10-22 AWG | 9001:2015 | 10-14 days |

| DuraFence International | 55-70 microns | 12-20 AWG | 14001:2015 | 21-28 days |

| ArmourTech Industries | 85-100 microns | 8-18 AWG | 9001/45001 | 7-10 days |

Third-party verification confirms top-tier manufacturers maintain consistent zinc application within ±5 microns across production batches.

Customisation Specifications

Project-specific adaptations typically include:

- Aperture Dimensions: Tolerance control of ±0.15mm for precision applications

- Edge Configurations: Reinforced selvage edges or welded border wires

- Hybrid Systems: PVC-galvanised dual coatings for chemical environments

The Liverpool Docks project required a custom rhomboid pattern with 38mm major axis openings to accommodate tidal forces, reducing material stress by 22% compared to standard square mesh.

Specialist Installation Protocols

Correct implementation prevents premature failure:

- Thermal expansion gaps of 5mm per linear metre

- Stainless steel fasteners to prevent bimetallic corrosion

- Polymer buffer strips for concrete embedding

Compression tensioning systems maintain mesh stability under load, with hydraulic tensioners applying calibrated force of 18-22 kN during perimeter securing.

Documented Application Results

Notable implementations demonstrate performance:

- Brisbane Airport Perimeter: 25km barrier resisting 120km/h cyclonic winds

- Norwegian Aquaculture: Mesh enclosures lasting 15+ years in seawater

- Automotive Testing: Crash barriers absorbing 85kJ impact energy

Maintenance logs from the Thames Barrier installation show corrosion rates 40% lower than initial projections after 12 years of tidal exposure.

Optimising Steel Galvanised Mesh Selection

Professionals should prioritise specifications over price considerations:

- Demand mill test certificates validating coating thickness

- Specify continuous mesh runs exceeding production seams

- Request sample panels for third-party verification

Verified galv steel mesh typically provides a 12-18 year service advantage over non-galvanised alternatives when properly specified. This translates to lifecycle cost reductions of 30-45% across industrial applications.

(steel galvanised mesh)

FAQS on steel galvanised mesh

Q: What is galvanised steel mesh used for?

A: Galvanised steel mesh is commonly used for fencing, construction reinforcement, and agricultural applications. Its zinc coating provides corrosion resistance, making it ideal for outdoor or high-moisture environments. It’s also used in industrial filtration and safety barriers.

Q: How does galvanised steel wire mesh resist rust?

A: The galvanisation process involves coating steel wire with a protective zinc layer. This layer acts as a barrier against moisture and oxygen, preventing rust formation. Even if scratched, the zinc sacrificially corrodes first, extending the mesh’s lifespan.

Q: Can steel galvanised mesh withstand extreme weather conditions?

A: Yes, galvanised steel mesh is highly durable in harsh weather due to its rust-resistant zinc coating. It performs well in rain, snow, and high humidity. However, prolonged exposure to acidic or saline environments may require additional protective measures.

Q: What are the advantages of using galvanised steel mesh over PVC-coated mesh?

A: Galvanised steel mesh offers superior strength and longevity compared to PVC-coated alternatives. It doesn’t degrade under UV exposure and maintains structural integrity at higher temperatures. The zinc coating also requires less maintenance over time.

Q: How do I choose the right gauge for galvanised steel wire mesh?

A: Select the gauge based on your project’s load and durability requirements. Thicker gauges (lower numbers) suit heavy-duty applications like industrial fencing, while thinner gauges work for lightweight uses like garden mesh. Always consider environmental factors and tension needs.

-

Why Nylon Mesh Netting is Revolutionizing Industrial and Commercial ApplicationsNewsJun.13,2025

-

Reinventing Reliability with Construction Wire MeshNewsJun.13,2025

-

Protect Your Crops with High-Performance Agricultural Netting SolutionsNewsJun.13,2025

-

Premium Breeding Net Solutions for Modern AquariumsNewsJun.13,2025

-

Precision Filtration Solutions for Industrial and Commercial NeedsNewsJun.13,2025

-

Advanced Industrial Mesh Solutions for Every ApplicationNewsJun.13,2025