-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

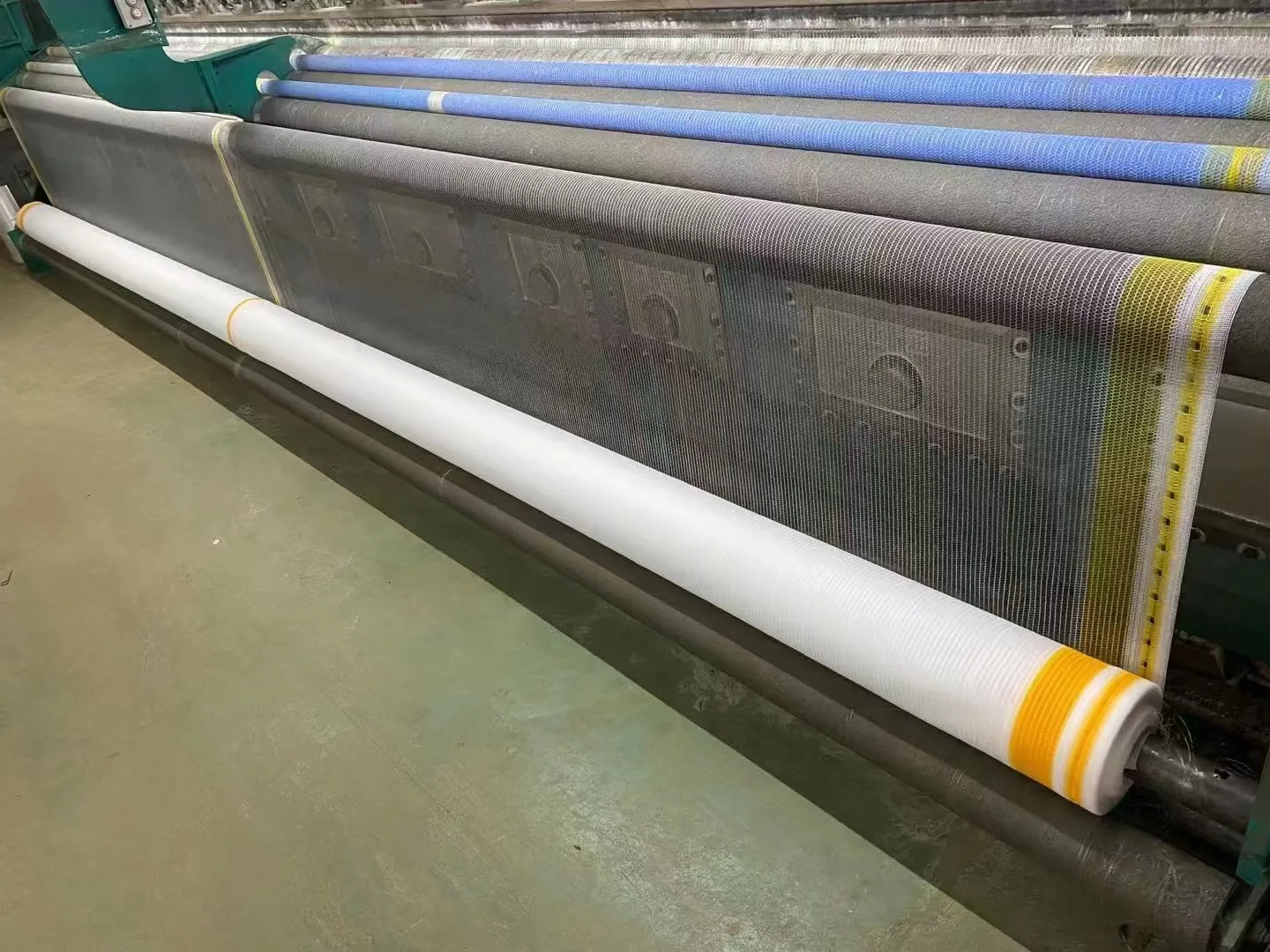

50 percent nylon mesh for filtration and various industrial applications

Exploring the Benefits of 50% 20 Micron Nylon Mesh

In the world of filtration and separation technologies, the choice of materials plays a crucial role in determining the efficiency and effectiveness of the process. Among various options, 20 micron nylon mesh has emerged as a popular choice, particularly when utilized at a 50% density. This article explores the benefits and applications of 50% 20 micron nylon mesh, offering insights into its functionality and advantages across various industries.

Exploring the Benefits of 50% 20 Micron Nylon Mesh

One of the most significant benefits of 50% 20 micron nylon mesh is its ability to balance filtration efficiency with fluid flow. In applications where the removal of particulates is essential—such as in water treatment, pharmaceuticals, or food processing—the mesh provides an effective barrier to contaminants while preventing excessive pressure buildup. This balance ensures that systems operate smoothly, minimizing the risk of clogs or backpressure that can harm equipment or disrupt processes.

50 micron nylon mesh

Moreover, nylon is resistant to many chemicals, making it suitable for use in diverse environments. The 50% 20 micron nylon mesh demonstrates resilience to various solvents and acids, ensuring longevity and reliability even in challenging conditions. This durability reduces the frequency and cost of replacements, making it an economical choice for businesses and industries that rely on consistent performance.

In addition to its physical properties, the nylon mesh is lightweight and easy to handle, which simplifies installation and maintenance. Whether it is used in mechanical filtration setups, sieves, or industrial separation systems, operators find that its adaptability allows for seamless integration into existing processes. Its lightweight nature also means that transporting and installing the mesh is less labor-intensive than heavier alternatives.

Applications of 50% 20 micron nylon mesh are extensive and varied. In the food and beverage industry, it is commonly used for brewing processes, where distinguishing between solid and liquid components is vital. Similarly, in pharmaceuticals, it aids in filtering active ingredients from solvents, ensuring product purity. Additionally, the automotive and aerospace sectors utilize nylon mesh for air and liquid filtration systems, where precision is paramount.

In conclusion, 50% 20 micron nylon mesh is a versatile and effective material that plays a crucial role in various industrial applications. Its ability to combine robust filtration efficiency with reliable flow rates, chemical resistance, and ease of use makes it an excellent choice for businesses seeking to enhance their operational capabilities. As industries continue to prioritize efficiency and cost-effectiveness, the demand for materials like 50% 20 micron nylon mesh is likely to grow, further solidifying its position as a key player in filtration technology.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025