-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 23, 2025 05:10

Back to list

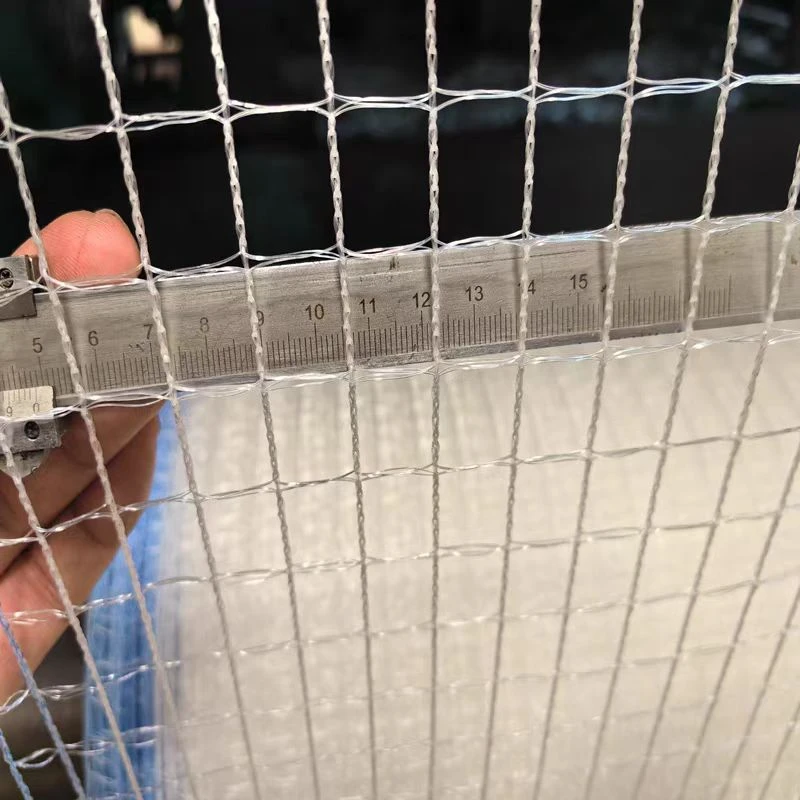

Nylon Filter Mesh

Bolting cloth is an essential component in the world of screen printing, often underestimated yet pivotal in achieving high-quality prints. This material, characterized by its precise mesh construction, forms the backbone of the screen printing process. It is instrumental not just in supporting the emulsion but also in aiding the transfer of inks with remarkable precision.

Moreover, the versatility of bolting cloth extends beyond traditional printing. It finds applications in industries like electronics, ceramics, and medical devices, where precision screen printing is vital. For instance, creating circuit boards demands a high degree of accuracy, which bolting cloth, with its finely woven fibers, can provide. This versatility reinforces the cloth's authority in varied industrial applications. In terms of maintenance, trustworthiness is emphasized through proper care and handling of bolting cloth, prolonging its life and ensuring consistent performance. Cleaning with gentle solutions and storing it in controlled environments prevents damage and contamination. Professionals recommend routine inspections for wear and tear, ensuring that any compromised cloth is replaced promptly to avoid disruptions in quality. Experts in the field often share insights and updates on advancements in bolting cloth technology, such as developments in fabric treatments enhancing durability or new mesh weaves improving detail reproduction. These innovations contribute to the evolving expertise surrounding screen printing, as practitioners gain from a wealth of knowledge shared through industry publications, workshops, and trade shows. Ultimately, bolting cloth is not merely a tool but an integral component of the screen printing process, embodying the precision, durability, and versatility required for diverse print jobs. Its successful utilization demands a combination of deep product knowledge, practical experience, and meticulous attention to maintenance, ensuring that each print not only meets but exceeds the expected standards of quality.

Moreover, the versatility of bolting cloth extends beyond traditional printing. It finds applications in industries like electronics, ceramics, and medical devices, where precision screen printing is vital. For instance, creating circuit boards demands a high degree of accuracy, which bolting cloth, with its finely woven fibers, can provide. This versatility reinforces the cloth's authority in varied industrial applications. In terms of maintenance, trustworthiness is emphasized through proper care and handling of bolting cloth, prolonging its life and ensuring consistent performance. Cleaning with gentle solutions and storing it in controlled environments prevents damage and contamination. Professionals recommend routine inspections for wear and tear, ensuring that any compromised cloth is replaced promptly to avoid disruptions in quality. Experts in the field often share insights and updates on advancements in bolting cloth technology, such as developments in fabric treatments enhancing durability or new mesh weaves improving detail reproduction. These innovations contribute to the evolving expertise surrounding screen printing, as practitioners gain from a wealth of knowledge shared through industry publications, workshops, and trade shows. Ultimately, bolting cloth is not merely a tool but an integral component of the screen printing process, embodying the precision, durability, and versatility required for diverse print jobs. Its successful utilization demands a combination of deep product knowledge, practical experience, and meticulous attention to maintenance, ensuring that each print not only meets but exceeds the expected standards of quality.

Latest news

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025