-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

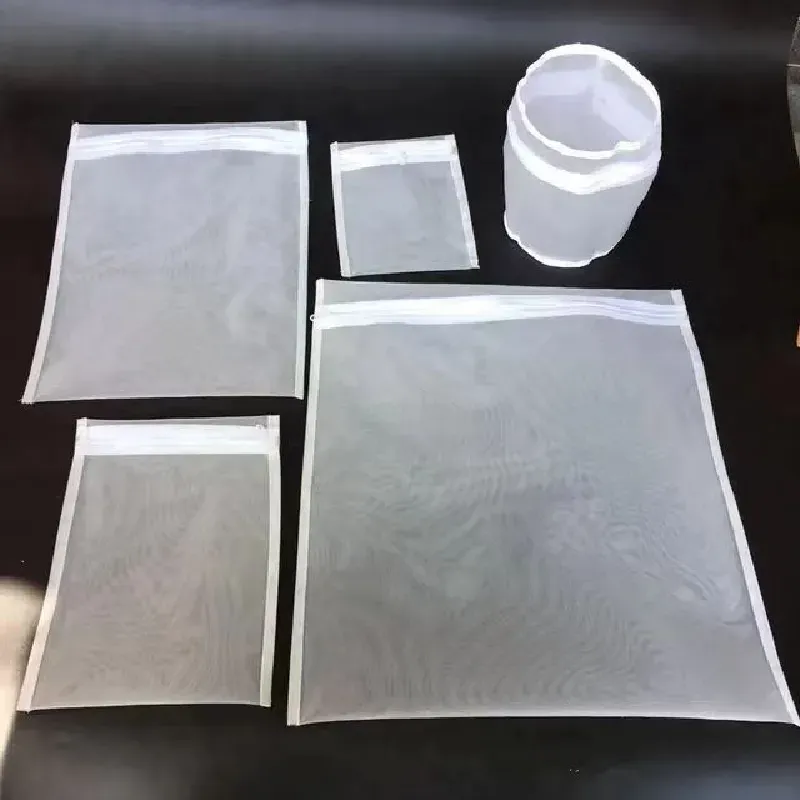

Application and Development of Nylon Screen in Fuel Processing and Treatment

Nylon screen has occupied an important position in the field of fuel processing because of its excellent physical properties and chemical stability. Whether in coal screening, bio-fuel separation or petroleum refining, nylon screen has shown high applicability and reliability.

Application of Nylon Screen in Fuel Industry

- Coal screening and preparation: In the process of coal processing, it is necessary to screen raw coal to remove sediment, stones and other impurities, and at the same time classify coal according to particle size to meet the needs of different combustion equipment. With its high strength and wear resistance, nylon screenhas been widely used in vibrating screen, roller screen and other equipment.

- Filtration and separation in petrochemical industry: In the process of petroleum refining and chemical industry, nylon meshcan be used to separate suspended solid particles in crude oil and ensure the purity of oil products in the process of refined oil filtration. Especially in some crude oil treatment with more sand, nylon screenshows excellent anti-blocking performance.

- Liquid-solid separation in biofuel production: In the production of biofuels (such as ethanol, biogas and biodiesel), it is often necessary to separate solid substances from fermentation broth or waste. Nylon screenis widely used in centrifuges, filters and other equipment for its fine mesh and chemical corrosion resistance, ensuring efficient and stable separation process.

- Liquefaction and purification of natural gas: In the process of natural gas liquefaction and transportation, nylon nettingis used to filter solid particles and impurities in the transportation pipeline, prevent pipeline blockage and equipment wear, and ensure the purity and transmission efficiency of natural gas.

- Filtration of fuel additives: During the production and use of fuel additives (such as detergents and antioxidants), it is necessary to filter the solution to remove insoluble particles or control the particle size of additives. The chemical stability and high precision of nylon screenensure the efficient operation of this link.

Use and Maintenance of Nylon Screen

In order to ensure the best performance of nylon screen in fuel processing, the following are some suggestions for use and maintenance:

-

Regular cleaning: particles and impurities in fuel processing are easy to block the screen, so it should be cleaned regularly to keep the mesh open and ensure the screening efficiency.

-

Control tension: nylon screenshould be properly tensioned during installation. Too loose will affect the screening effect, while too tight may lead to mesh deformation or screen damage.

-

Prevention of mechanical damage: During use, the screen should be prevented from being scratched by sharp objects, and the equipment should run smoothly to prevent the screen from being damaged due to strong impact.

-

Regular inspection and replacement: Although the nylon mesh nettinghas a long service life, it may still be aging in a long-term high-load environment, so it needs to be inspected regularly and replaced as appropriate.

-

Avoid exceeding the temperature tolerance range: Although nylon screenhas certain high temperature resistance, it may lead to material performance degradation in an environment above its tolerance range, which should be avoided as far as possible.

Future Development Trend of Nylon Screen

-

Modification of new materials: By modifying nylon filter mesh, such as adding nanoparticles or coating technology, its wear resistance, anti-blocking performance and high temperature resistance can be further improved.

-

Intelligent screen equipment: Combined with sensor technology, intelligent screen equipment that can monitor the mesh state, particle distribution and separation efficiency in real time is developed to improve the automation level of processing.

-

Optimization of environmental protection performance: develop more environmentally friendly nylon mesh materialsor biodegradable screens to further reduce the environmental impact of screen manufacturing and use.

-

High-precision microfiltration technology: meet the requirements of the fuel industry for the classification and separation of ultrafine particles, develop a nylon screenwith higher precision, and further improve the fuel quality.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025