-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

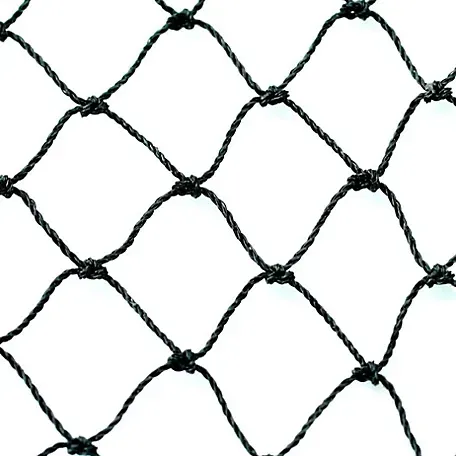

Durable Bird Netting for Gardens, Farms & Property Protection

The Strategic Imperative of Advanced Bird Net Solutions in Modern Agriculture and Beyond

In contemporary agriculture, aquaculture, and various industrial sectors, the protection of crops, fisheries, and infrastructure from avian interference is paramount for ensuring productivity and economic viability. The global market for bird control solutions, particularly those involving physical barriers, has witnessed significant growth, driven by escalating demand for sustainable and non-lethal methods. Industry trends indicate a pronounced shift towards highly durable, UV-stabilized materials like High-Density Polyethylene (HDPE) due to their extended lifespan and superior resistance to environmental degradation. As agricultural practices become more intensified and specialized, the precision and reliability of protective measures become critical. The implementation of robust bird net solutions not only mitigates direct damage but also contributes to biosecurity and the overall ecological balance by deterring pests without harming them. Furthermore, the integration of advanced netting technology reduces reliance on chemical deterrents, aligning with growing consumer preferences for organically grown produce and environmentally conscious cultivation methods. This comprehensive approach safeguards investments and yields, establishing these netting solutions as an indispensable component of modern, efficient, and sustainable operational frameworks across diverse industries requiring avian exclusion.

Detailed Technical Specifications: HDPE Anti-Bird Net

The design and material composition of a high-performance bird net are critical factors determining its efficacy, longevity, and overall return on investment. Our Hot Sale Factory directly 100% HDPE Anti-Bird Net for Garden/Agriculture exemplifies advanced engineering in protective netting. Crafted from virgin High-Density Polyethylene (HDPE), known for its exceptional strength-to-density ratio, chemical resistance, and inertness, this material ensures a robust barrier. The inclusion of UV stabilizers during the manufacturing process is a key technical advantage, significantly extending the net's operational lifespan by preventing degradation from prolonged sun exposure, which is a common failure point for lesser quality materials. Mesh sizes are meticulously engineered to effectively exclude specific bird species while allowing for optimal airflow and light penetration, crucial for crop growth. Filament thickness and tensile strength are calibrated to withstand environmental stresses, including wind, rain, and hail, without tearing or deforming. These precise technical parameters ensure the net provides reliable, long-term protection, safeguarding agricultural yields and critical infrastructure from avian incursions, thereby preserving economic value and ensuring operational continuity.

| Parameter | Specification / Value | Technical Significance |

|---|---|---|

| Material Composition | 100% Virgin HDPE (High-Density Polyethylene) | Ensures high tensile strength, chemical inertness, and resistance to environmental degradation. Superior to recycled materials for longevity. |

| UV Stabilization | Yes, > 3% UV Additives | Crucial for preventing photo-oxidation and material breakdown due to prolonged solar exposure, extending service life significantly. |

| Mesh Size | Typically 15mm x 15mm to 30mm x 30mm (customizable) | Optimized to effectively exclude targeted bird species while allowing essential light, air, and insect passage (for pollination). |

| Density | 0.95 - 0.97 g/cm³ | Indicates material purity and structural integrity, contributing to strength and durability. |

| Tensile Strength (Warp/Weft) | > 300 N / 5cm (typical, varies by denier) | Measures resistance to breaking under tension, critical for enduring wind loads, bird impacts, and installation stresses. |

| Service Life (Expected) | 5-10+ years (dependent on UV exposure and installation) | High longevity reduces replacement frequency and overall cost of ownership, providing a long-term protective solution. |

| Weight (GSM - Grams per Square Meter) | 10-40 GSM (variable based on denier and weave) | Influences ease of handling, installation, and wind resistance. Lower GSM for lighter applications, higher for more robust needs. |

| Color Options | Black, Green, White (customizable) | Allows for aesthetic integration or specific light transmission properties, e.g., black for maximum UV absorption, white for maximum reflection. |

Manufacturing Process: Ensuring Uncompromised Quality and Durability

The production of high-quality bird net solutions is a sophisticated process that leverages advanced polymer extrusion and knitting technologies to ensure uniform strength, consistent mesh size, and enduring performance. The journey begins with the selection of premium, 100% virgin HDPE granules, which are fed into industrial extruders. Within the extruder, the HDPE is melted under precise temperature controls and then forced through a die to form continuous filaments. Crucially, UV stabilizers, typically hindered amine light stabilizers (HALS), are homogeneously blended into the polymer melt at this stage, imparting long-term resistance to photodegradation. These filaments are then stretched, or drawn, in a multi-stage process to align the polymer chains, significantly enhancing the material's tensile strength and stiffness – a process akin to cold forging in metallurgy, but for polymers. Following extrusion and drawing, the filaments are spooled and transferred to advanced knitting machines. Here, various knitting patterns, such as Raschel or Leno weave, are employed to create the desired mesh configuration. The choice of weave impacts the net's tear resistance, flexibility, and overall stability. Rigorous quality control measures are integrated throughout this entire process, from raw material inspection to in-line monitoring of filament diameter and consistency.

Post-knitting, the netting undergoes a series of crucial finishing processes, including heat setting, which stabilizes the mesh structure and prevents shrinkage, ensuring dimensional stability over its service life. This step is vital for maintaining the specified mesh aperture under varying environmental conditions. Subsequently, each batch of netting is subjected to stringent testing protocols to certify compliance with international quality standards such as ISO 9001 for quality management systems and specific ASTM or EN standards for material properties like tensile strength, tear resistance, and UV stability. Testing often involves accelerated weathering chambers simulating years of outdoor exposure to validate the effectiveness of UV stabilization. For specialized applications, tests may also include fire retardancy or specific load-bearing capacities. The final product is then carefully inspected for any manufacturing defects before being cut to specification, rolled, and packaged for shipment. This meticulous multi-stage manufacturing and rigorous testing regimen guarantees that each bird net delivered is of the highest quality, offering reliable, long-term protection against avian pests while maximizing return on investment for end-users across diverse sectors like agriculture, aquaculture, industrial facilities, and municipal infrastructure.

Diverse Application Scenarios and Distinct Technical Advantages

The versatility of robust bird net solutions extends across a broad spectrum of industries, providing essential protection in environments where avian interference poses a significant threat to productivity, safety, or public health. In the agricultural sector, these nets are indispensable for safeguarding vineyards, orchards, berry farms, and vegetable plots from bird predation, which can result in substantial crop loss – often exceeding 20-30% in high-risk areas. For aquaculture, particularly in fish farms and shrimp ponds, netting prevents birds from preying on valuable stock, thereby mitigating economic losses and disease transmission pathways. Industrial and commercial facilities, including warehouses, airports, and solar farms, utilize bird netting to prevent nesting and roosting, which can cause structural damage, create health hazards from droppings, or interfere with operational machinery and sensitive equipment. Moreover, municipal infrastructure like bridges, historical buildings, and public parks deploy netting for aesthetic preservation and to reduce maintenance costs associated with bird waste. The primary technical advantage lies in the net's ability to provide a durable, non-lethal physical barrier. Unlike acoustic deterrents or chemical repellents, which birds can habituate to or are environmentally undesirable, a physical net offers consistent, passive, and environmentally friendly protection, ensuring long-term efficacy without harming wildlife.

Beyond its primary function as a physical barrier, the advanced material science behind modern bird net systems offers several crucial technical advantages that translate directly into operational benefits. The use of high-grade HDPE, infused with specialized UV stabilizers, ensures an exceptional lifespan, typically ranging from 5 to over 10 years, significantly reducing the frequency and cost of replacement compared to conventional materials. This durability also translates into high resistance against adverse weather conditions, including strong winds, heavy rainfall, and hail, maintaining structural integrity and protective capability even under extreme environmental stressors. Furthermore, the light weight of HDPE netting simplifies installation and removal processes, reducing labor costs and potential structural load on supporting frameworks. The precise mesh geometry, designed for optimal airflow and light transmission, ensures that protected crops receive adequate sunlight and ventilation, fostering healthy growth while deterring birds. This technical harmony between protection and environmental compatibility makes advanced bird netting a superior choice over traditional or less sustainable methods, offering a cost-effective, long-term solution that contributes to both ecological responsibility and economic prosperity in various critical applications where avian pest control is a necessity.

Optimizing Procurement: Manufacturer Comparison and Customization Solutions

When sourcing high-performance bird net solutions, B2B decision-makers must consider several critical factors beyond initial cost, including material quality, manufacturing precision, customization capabilities, and post-sales support, to ensure optimal value and long-term performance. While numerous manufacturers exist, a discernible difference often emerges in their commitment to virgin HDPE materials, the consistency of UV stabilization, and adherence to international manufacturing standards like ISO 9001. Manufacturers employing rigorous quality control at every stage, from raw material inspection to final product testing, typically offer superior product reliability and an extended service life. For instance, a factory directly manufacturing from 100% virgin HDPE, rather than recycled content, ensures higher tensile strength and predictable performance against environmental stressors. Evaluating a manufacturer’s experience, certified production processes, and proven track record with large-scale industrial or agricultural projects provides a reliable indicator of their capability to deliver consistent, high-quality netting solutions. This due diligence process is crucial for mitigating risks associated with premature material degradation, inconsistent mesh sizing, or insufficient UV resistance, all of which can lead to costly re-installations and significant operational disruptions.

Beyond standard product offerings, the ability to provide comprehensive customization solutions is a distinguishing characteristic of leading bird net manufacturers, enabling clients to address unique challenges with precision-engineered products. Customization extends to various parameters, including specific mesh sizes tailored to exclude particular bird species (e.g., smaller meshes for sparrows, larger for pigeons), precise netting dimensions to fit complex architectural structures or vast agricultural expanses without excessive seaming, and tailored filament deniers to achieve specific strength-to-weight ratios. Furthermore, specialized color options can be provided to either blend aesthetically with the environment or to optimize light reflection/absorption for crop-specific requirements. For large-scale projects, manufacturers often collaborate closely with clients to develop bespoke installation methodologies or provide pre-fabricated net sections for expedited deployment. This level of customized engineering ensures that the netting solution is not merely a product but an integral component of a strategic protection system, perfectly integrated into the existing operational environment, thereby maximizing effectiveness and minimizing waste while delivering a superior return on investment for complex and mission-critical applications where standard solutions are insufficient.

Real-World Application Case Studies and Company Authority

The tangible benefits and proven efficacy of advanced bird net solutions are best illustrated through successful application case studies, which demonstrate how precise engineering and material quality translate into significant operational improvements and economic savings for diverse clients. For instance, a prominent vineyard in Napa Valley, California, faced recurring crop losses exceeding 15% annually due to bird predation, particularly during the critical ripening stages of its high-value grape varietals. By implementing a custom-designed overhead netting system utilizing UV-stabilized HDPE netting with a 20mm x 20mm mesh, the vineyard reported a dramatic reduction in crop damage, with losses dropping to less than 1% over three consecutive harvest seasons. This direct intervention not only safeguarded revenue but also enhanced the consistent quality of their produce. Similarly, a large-scale commercial fish farm in Southeast Asia, battling substantial economic losses from avian predation on their juvenile fish stocks, installed robust perimeter and overhead netting. Within six months, the farm documented a 25% reduction in stock loss attributed to birds, leading to an impressive ROI within two years. These real-world examples underscore the direct financial and operational benefits derived from investing in high-quality, purpose-built bird netting systems that are engineered for specific challenges.

Our company’s authority in the field of protective netting is underscored by over two decades of specialized manufacturing experience, a robust portfolio of certifications, and a steadfast commitment to pioneering material science. We operate under stringent ISO 9001:2015 certified quality management systems, ensuring that every stage of our production, from raw material sourcing to final product inspection, adheres to the highest international benchmarks for consistency and performance. Our products, including the Hot Sale Factory directly 100% HDPE Anti-Bird Net, consistently pass rigorous internal and third-party testing for tensile strength (e.g., ASTM D638, ISO 527), UV stability (e.g., accelerated weathering tests per ASTM G154), and tear resistance, validating their durability and longevity. Furthermore, our long-standing collaborations with major agricultural cooperatives, leading aquaculture enterprises, and large-scale industrial developers globally, serve as a testament to the trust and reliability our clients place in our solutions. These partnerships, often spanning multiple years and projects, reflect our capability to deliver not just products, but comprehensive, custom-engineered protective systems that meet the most demanding specifications and provide unparalleled value, ensuring our position as a trusted and authoritative supplier in the global market for high-performance netting solutions.

Frequently Asked Questions (FAQ) About Bird Netting Solutions

Q1: What makes HDPE superior to other materials for bird net applications?

High-Density Polyethylene (HDPE) stands out due to its exceptional strength-to-weight ratio, remarkable resistance to chemicals, moisture, and rot, and its inherent durability. Unlike nylon or polypropylene, HDPE is more resistant to UV degradation when properly stabilized, ensuring a significantly longer service life in outdoor conditions without becoming brittle or losing tensile strength. Its non-absorbent nature also prevents fungal growth and maintains structural integrity in humid environments. The material’s robust nature ensures that it can withstand repeated impacts from birds, resist tearing from strong winds, and maintain its structural integrity over many years, offering a more reliable and cost-effective long-term solution for various protective applications. This robust composition makes HDPE the material of choice for demanding agricultural and industrial bird exclusion projects, providing a superior balance of performance, longevity, and environmental resistance compared to alternative polymers, leading to reduced maintenance and replacement costs over the operational life of the system.

Q2: How do you determine the correct mesh size for specific bird species?

Determining the appropriate mesh size for a bird net is a critical engineering decision based primarily on the target bird species to be excluded and the specific application requirements. For smaller birds such as sparrows, starlings, or finches, a finer mesh of typically 15mm x 15mm or 19mm x 19mm is recommended to prevent their entry. For larger species like pigeons, gulls, or crows, a wider mesh of 28mm x 28mm or 50mm x 50mm may be sufficient, which also allows for better light and air penetration. Our technical team works closely with clients to identify the primary avian threats based on geographical location, specific crop types, or industrial environment to recommend the most effective mesh configuration. This consultative approach ensures that the netting system provides adequate protection without unnecessarily impeding light or air, optimizing both efficacy and environmental compatibility for the specific pest control challenge at hand. Precision in mesh sizing ensures maximum deterrent effect while minimizing any potential impact on the protected environment, such as reduced sunlight for crops or restricted air circulation in enclosed spaces.

Q3: What is the typical lifespan of your HDPE anti-bird net, and what factors affect it?

Our 100% virgin HDPE bird net, specifically engineered with advanced UV stabilization additives, is designed for an extended service life, typically ranging from 5 to 10+ years under normal outdoor conditions. Several critical factors influence its overall longevity. The primary factor is exposure to intense ultraviolet (UV) radiation from sunlight; our integrated UV stabilizers significantly mitigate this, but extreme, prolonged exposure in high-altitude or equatorial regions might slightly reduce the lifespan compared to temperate zones. Mechanical stress, such as strong winds, abrasive contact with sharp structures, or impacts from falling debris, can also affect durability; proper installation with tensioning systems and adequate support structures can minimize such stresses. Additionally, the presence of certain chemicals in agricultural sprays or industrial environments could potentially influence material integrity over very long periods, though HDPE generally exhibits excellent chemical resistance. Adherence to recommended installation guidelines and periodic maintenance checks are crucial for maximizing the net’s operational life and ensuring its continued protective efficacy against avian pests, thereby optimizing the return on investment for the end-user over many seasons or operational cycles.

Streamlined Delivery and Robust Warranty Commitment

Understanding the critical timelines inherent in B2B procurement, particularly for seasonal agricultural demands or urgent industrial protection needs, our logistics and delivery processes for bird net solutions are meticulously streamlined to ensure efficiency and reliability. Upon confirmation of an order, our production schedule is immediately optimized to prioritize manufacturing and quality assurance, leveraging advanced production capabilities to meet volume requirements without compromising quality. Typical lead times for standard products range from 7 to 15 business days, depending on order size and current factory load. For customized solutions or large-scale projects, a detailed production and delivery schedule is collaboratively developed with the client, often incorporating phased shipments to align with project installation timelines. We work with reputable global freight forwarders and logistics partners, offering various shipping options including sea freight (for cost-effectiveness on large orders), air freight (for expedited delivery), and land transport, tailored to the client's geographical location and urgency. All shipments are meticulously packaged to prevent damage during transit, ensuring the product arrives in pristine condition and ready for immediate deployment, thereby minimizing downtime and maximizing the client's operational continuity.

Our confidence in the superior quality and enduring performance of our Hot Sale Factory directly 100% HDPE Anti-Bird Net is reflected in our comprehensive warranty commitment and proactive customer support. We provide a standard multi-year warranty (typically 5-7 years, with specific terms outlined per product series), covering manufacturing defects and premature material degradation under normal usage conditions, excluding damage from improper installation or extreme unforeseen events. This warranty is a testament to our rigorous quality control processes, the use of virgin HDPE materials, and the efficacy of our UV stabilization technology, which collectively ensure the net's longevity and performance against environmental stressors. In the unlikely event of a quality issue, our dedicated customer support team is available to provide prompt technical assistance, troubleshooting, and resolution, ensuring minimal disruption to client operations. Our commitment extends beyond mere product delivery; we strive to establish long-term partnerships by offering continuous technical support, guidance on optimal installation practices, and expert advice on maximizing the lifespan and effectiveness of our bird net solutions, solidifying our position as a reliable and trusted supplier for critical protective applications.

References

- ISO 9001:2015 Quality management systems — Requirements. International Organization for Standardization.

- ASTM International. Standard Test Methods for Tensile Properties of Plastics (ASTM D638).

- ASTM International. Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials (ASTM G154).

- Polyethylene Handbook: Polymerization, Processing, Properties, and Applications.

- Bird Damage to Agriculture: Biological and Economic Considerations. Journal of Wildlife Management.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025