-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

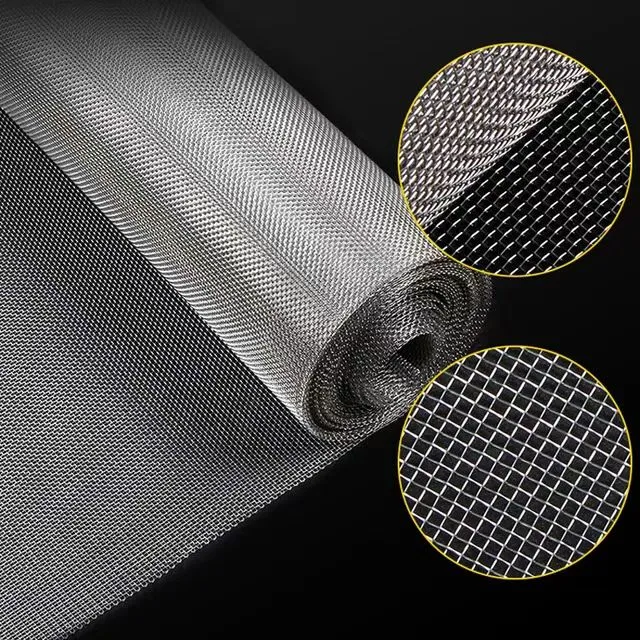

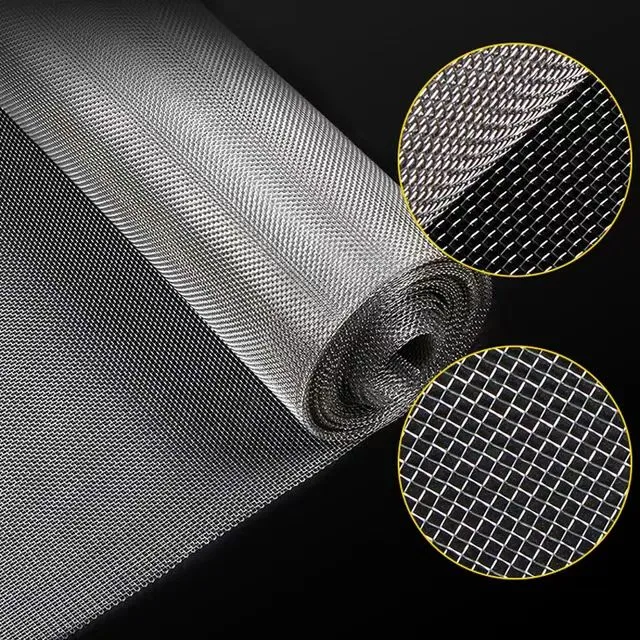

Enhancing Workplace Safety with Steel Mesh Screen

In industrial settings, ensuring the safety of workers is paramount. One effective way to enhance safety is by using a steel mesh screen. These screens act as barriers that prevent objects from falling, reducing the risk of accidents. For example, in construction sites or manufacturing facilities, steel mesh screens can be installed around high-risk areas to contain debris and protect workers below. The durability of steel makes these screens a reliable option, capable of withstanding the harsh conditions often found in industrial environments. By integrating steel mesh screens into your safety strategy, you can significantly reduce the likelihood of injuries caused by falling objects.

The Role of Steel Mesh for Concrete in Structural Safety

When it comes to reinforcing concrete structures, steel mesh for concrete is an essential component. This type of mesh provides additional strength to concrete, helping it withstand heavy loads and extreme conditions. In industrial settings, where large machinery and heavy equipment are common, using steel mesh for concrete ensures that floors, walls, and other structures can handle the pressure without cracking or breaking. The mesh acts as a reinforcement that distributes weight more evenly, reducing the risk of structural failure. Incorporating steel mesh for concrete in your construction projects is a proactive measure that enhances the overall safety and longevity of industrial buildings.

Stainless Steel Hardware Cloth

Another critical aspect of industrial safety is protecting workers from contact with hazardous materials or machinery. Stainless steel hardware cloth is an excellent solution for creating protective barriers around dangerous equipment or sensitive areas. This mesh is made from stainless steel, offering corrosion resistance and durability, even in harsh industrial environments. Stainless steel hardware cloth can be used to cover vents, enclose machinery, or create partitions that keep workers safe from potential harm. Its fine mesh design allows visibility and ventilation while providing a strong barrier that prevents accidental injuries. By implementing stainless steel hardware cloth in your safety protocols, you can ensure a safer work environment for all employees.

The Importance of Stainless Steel Woven Mesh in Industrial Applications

Stainless steel woven mesh is another versatile material that plays a crucial role in industrial safety. This mesh is woven from high-quality stainless steel wires, creating a strong yet flexible barrier that can be used in various applications. In industries where contamination is a concern, such as food processing or pharmaceuticals, stainless steel woven mesh is often used to filter particles and protect against impurities. Additionally, it can be used in fencing, screening, and other protective applications to keep workers safe from potential hazards. The corrosion-resistant nature of stainless steel woven mesh ensures long-lasting performance, making it an ideal choice for maintaining safety standards in industrial environments.

Integrating Water Hammer Arrestor Dishwasher for Equipment Protection

While not a traditional safety barrier, the water hammer arrestor dishwasher is an important component in preventing equipment damage and ensuring operational safety. Water hammer, a common issue in industrial plumbing systems, occurs when a sudden change in water flow creates a pressure surge that can damage pipes and equipment. Installing a water hammer arrestor dishwasher helps to absorb these pressure spikes, protecting the plumbing system and preventing potential leaks or bursts. This, in turn, contributes to a safer working environment by reducing the risk of water damage or equipment failure. By incorporating water hammer arrestor dishwasher units into your facility’s plumbing, you can protect your investment and maintain a safer, more reliable operation.

The Versatility of Steel Mesh Screen in Industrial Safety

The applications of steel mesh screen in industrial safety are vast and varied. Beyond preventing objects from falling, these screens can be used to create secure enclosures around hazardous areas, such as machinery with moving parts or high-voltage equipment. Steel mesh screens are also ideal for creating walkways or platforms, providing a non-slip surface that enhances worker safety. The adaptability of steel mesh makes it a go-to material for industrial safety solutions, offering both protection and visibility. Whether you're securing a construction site, reinforcing a warehouse, or ensuring safe access to elevated areas, steel mesh screen is an indispensable tool in the pursuit of workplace safety.

Each of these products plays a vital role in enhancing industrial safety, making them essential components of any comprehensive safety plan.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025

Enhancing Workplace Safety with Steel Mesh Screen

In industrial settings, ensuring the safety of workers is paramount. One effective way to enhance safety is by using a steel mesh screen. These screens act as barriers that prevent objects from falling, reducing the risk of accidents. For example, in construction sites or manufacturing facilities, steel mesh screens can be installed around high-risk areas to contain debris and protect workers below. The durability of steel makes these screens a reliable option, capable of withstanding the harsh conditions often found in industrial environments. By integrating steel mesh screens into your safety strategy, you can significantly reduce the likelihood of injuries caused by falling objects.

Protecting Workers with Stainless SThe Role of Steel Mesh for Concrete in Structural Safety

When it comes to reinforcing concrete structures, steel mesh for concrete is an essential component. This type of mesh provides additional strength to concrete, helping it withstand heavy loads and extreme conditions. In industrial settings, where large machinery and heavy equipment are common, using steel mesh for concrete ensures that floors, walls, and other structures can handle the pressure without cracking or breaking. The mesh acts as a reinforcement that distributes weight more evenly, reducing the risk of structural failure. Incorporating steel mesh for concrete in your construction projects is a proactive measure that enhances the overall safety and longevity of industrial buildings.

Stainless Steel Hardware Cloth

Another critical aspect of industrial safety is protecting workers from contact with hazardous materials or machinery. Stainless steel hardware cloth is an excellent solution for creating protective barriers around dangerous equipment or sensitive areas. This mesh is made from stainless steel, offering corrosion resistance and durability, even in harsh industrial environments. Stainless steel hardware cloth can be used to cover vents, enclose machinery, or create partitions that keep workers safe from potential harm. Its fine mesh design allows visibility and ventilation while providing a strong barrier that prevents accidental injuries. By implementing stainless steel hardware cloth in your safety protocols, you can ensure a safer work environment for all employees.

The Importance of Stainless Steel Woven Mesh in Industrial Applications

Stainless steel woven mesh is another versatile material that plays a crucial role in industrial safety. This mesh is woven from high-quality stainless steel wires, creating a strong yet flexible barrier that can be used in various applications. In industries where contamination is a concern, such as food processing or pharmaceuticals, stainless steel woven mesh is often used to filter particles and protect against impurities. Additionally, it can be used in fencing, screening, and other protective applications to keep workers safe from potential hazards. The corrosion-resistant nature of stainless steel woven mesh ensures long-lasting performance, making it an ideal choice for maintaining safety standards in industrial environments.

Integrating Water Hammer Arrestor Dishwasher for Equipment Protection

While not a traditional safety barrier, the water hammer arrestor dishwasher is an important component in preventing equipment damage and ensuring operational safety. Water hammer, a common issue in industrial plumbing systems, occurs when a sudden change in water flow creates a pressure surge that can damage pipes and equipment. Installing a water hammer arrestor dishwasher helps to absorb these pressure spikes, protecting the plumbing system and preventing potential leaks or bursts. This, in turn, contributes to a safer working environment by reducing the risk of water damage or equipment failure. By incorporating water hammer arrestor dishwasher units into your facility’s plumbing, you can protect your investment and maintain a safer, more reliable operation. By incorporating water hammer arrestor dishwasher units into your facility’s plumbing, you can protect your investment and maintain a safer, more reliable operation.

The Versatility of Steel Mesh Screen in Industrial Safety

The applications of steel mesh screen in industrial safety are vast and varied. Beyond preventing objects from falling, these screens can be used to create secure enclosures around hazardous areas, such as machinery with moving parts or high-voltage equipment. Steel mesh screens are also ideal for creating walkways or platforms, providing a non-slip surface that enhances worker safety. The adaptability of steel mesh makes it a go-to material for industrial safety solutions, offering both protection and visibility. Whether you're securing a construction site, reinforcing a warehouse, or ensuring safe access to elevated areas, steel mesh screen is an indispensable tool in the pursuit of workplace safety.

Each of these products plays a vital role in enhancing industrial safety, making them essential components of any comprehensive safety plan.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025