-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Farm Shade Net: UV Protection for Crops & Livestock

Strategic Crop Protection: The Imperative of Advanced Farm Shade Nets

In the rapidly evolving agricultural landscape, optimizing yield and ensuring crop health are paramount. Modern farming necessitates innovative solutions to combat escalating environmental stressors, a need expertly addressed by advanced farm shade net technologies. These specialized nets are not merely physical barriers; they represent a crucial investment in sustainable agriculture, offering precise control over critical environmental factors. As global climate patterns become more unpredictable, integrating high-quality netting solutions into farm infrastructure becomes indispensable for mitigating risks and enhancing productivity across diverse agro-climatic zones.

The demand for sophisticated farm netting solutions is escalating, driven by global trends towards protected cultivation, organic farming, and resource efficiency. Farmers are increasingly recognizing the long-term economic benefits derived from reduced water consumption, decreased pest incidence, and comprehensive protection against extreme weather events such as hail and excessive solar radiation. This shift underscores a broader industry movement towards precision agriculture, where every input is optimized for maximum output and minimal environmental impact. Our commitment is to provide robust, high-performance netting that aligns with these cutting-edge agricultural practices, ensuring resilient and profitable operations.

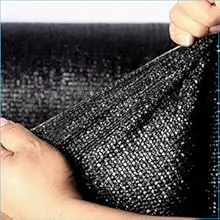

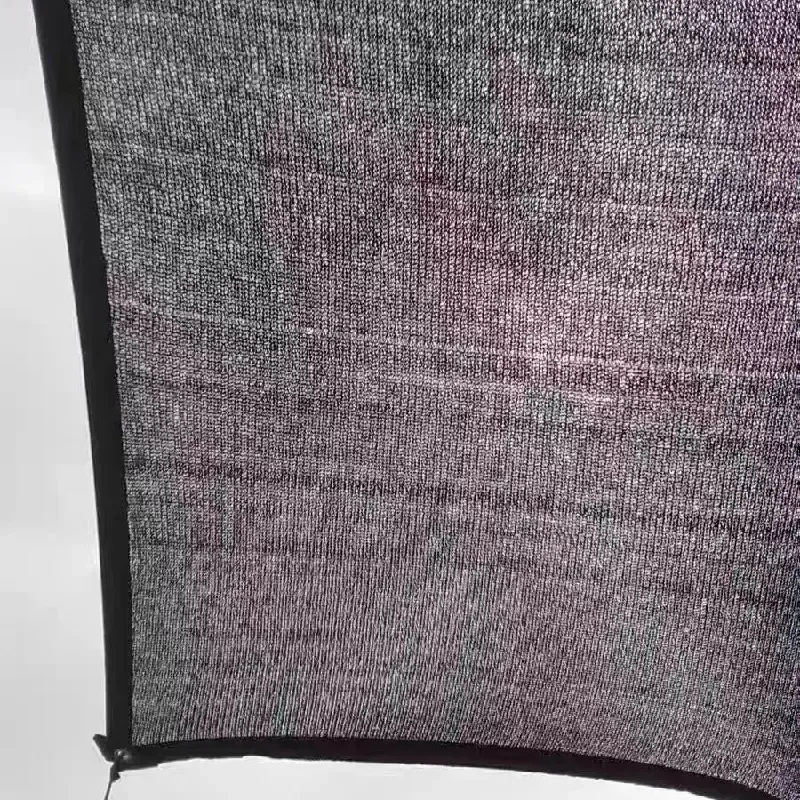

Craftsmanship Unveiled: The Manufacturing Process of High-Quality Shade Nets

The production of a superior net for farming involves a meticulous multi-stage process, ensuring unparalleled durability, functionality, and longevity. It begins with the selection of premium-grade High-Density Polyethylene (HDPE) virgin granules, known for their exceptional strength-to-density ratio, chemical inertness, and UV stability. This raw material is then precisely extruded into fine, uniform monofilaments or flat tapes, a critical step determining the ultimate tensile strength, consistent mesh density, and UV resistance of the final product. Advanced extrusion lines with precise temperature control ensure consistent denier and cross-sectional integrity of these filaments, minimizing material imperfections.

Following extrusion, these filaments undergo a specialized weaving or knitting process on state-of-the-art machinery. Depending on the desired shading percentage, wind permeability, and application (e.g., anti-hail, anti-insect, general shade), warp-knitted or woven structures are employed. Warp-knitted nets offer high elasticity, resistance to unraveling, and excellent air circulation, making them ideal for protective covers. Woven nets, conversely, provide superior strength, dimensional stability, and denser shade for general purposes. Crucially, high-performance UV stabilizers and anti-oxidants are uniformly incorporated into the HDPE formulation during extrusion, significantly extending the product's lifespan by protecting it from photodegradation. Our manufacturing adheres strictly to international quality management systems, including ISO 9001, ensuring every batch meets rigorous performance and safety benchmarks.

Post-production, each roll of shade net for farming undergoes a comprehensive series of quality assurance tests in our in-house laboratory. These include tensile strength testing (adhering to ASTM D638 or equivalent standards), tear resistance (ASTM D1004 equivalent), precise shading percentage verification, burst strength tests, and accelerated weathering tests using xenon arc or fluorescent UV lamps to simulate long-term solar exposure. The expected service life of our premium products typically ranges from 5 to 10 years, depending on the specific product grade, material density (GSM), and environmental conditions. Our nets are primarily applicable across various agricultural sectors including horticulture, floriculture, nurseries, fruit orchards, vineyards, aquaculture (for pond shading and algae control), and even livestock management, offering unparalleled protection against solar radiation, excessive heat, wind erosion, hail damage, and certain pests.

Technical Parameters & Performance Benchmarks

Understanding the technical specifications of a high-performance net for agriculture farming is crucial for making informed procurement decisions that directly impact crop health and operational efficiency. Our High Quality Farm Shade Net for Agriculture is engineered to deliver optimal performance under demanding conditions, leveraging precisely controlled technical attributes. Key parameters include the shading rate, which can range from 30% for light-sensitive crops such as orchids or young seedlings, to 90% for intensive shading requirements in scorching climates, and the density of UV stabilization, which is absolutely critical for extending product lifespan in high-irradiance environments. The material's inherent strength, expressed in grams per square meter (GSM), directly correlates with its overall durability, resistance to tearing under heavy wind loads, and resilience against physical stress from farm activities.

Below is a comprehensive table detailing typical technical specifications for our premium farm shade net offerings, based on industry-standard testing protocols and real-world performance data. These specifications ensure that our nets provide consistent protection and contribute to optimal plant growth, maximizing return on investment for agricultural businesses.

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Material Composition | Primary polymer used in manufacturing | 100% Virgin HDPE (High-Density Polyethylene) |

| Shading Rate (%) | Percentage of sunlight blocked (PAR light) | 30% - 90% (Customizable) |

| UV Stabilization Level | Concentration of UV inhibitors added | 5% - 8% (Benzophenone/Hindered Amine Light Stabilizers) |

| Weight (GSM) | Grams per Square Meter (Material Density) | 60 GSM - 300 GSM |

| Service Lifespan | Expected years of effective outdoor use | 5 - 10 years (Region/UV exposure dependent) |

| Standard Widths | Commonly available product widths | 1m, 2m, 3m, 4m, 6m (Larger custom widths available) |

| Tensile Strength | Force required to break (Warp/Weft) | >250 N/5cm (Warp), >150 N/5cm (Weft) (ASTM D638) |

| Tear Resistance | Resistance to propagation of a tear | >80 N (ASTM D1004) |

Applications and Case Studies: Real-World Impact

The versatility of a well-engineered farm netting solution extends across a myriad of agricultural applications, delivering tangible benefits in diverse growing environments and climates. From protecting delicate ornamental plants and exotic fruits in nurseries to shielding high-value fruit crops like berries and apples from excessive solar radiation and bird damage, the strategic deployment of these nets optimizes growing conditions year-round. They are also increasingly vital in advanced greenhouse environments, where they precisely regulate internal temperatures, significantly reduce water evaporation through evapotranspiration control, and manage light intensity, thereby improving crop quality, accelerating growth cycles, and enhancing overall yield consistency.

Consider a compelling case study from a large-scale pepper farm located in a subtropical region, notorious for its intense summer heatwaves and occasional hailstorms. This farm faced consistent issues with sunscald, reduced fruit setting, and significant yield losses due to unpredicted hail events. After consulting with our agricultural engineers, the farm implemented a comprehensive overhead system utilizing our 50% farm shade net with enhanced anti-hail properties. Over a single growing season, they reported a remarkable 18% increase in marketable yield due to drastically reduced sun damage and an almost complete elimination of hail-related losses. Furthermore, the stable microclimate created by the net fostered healthier plant growth and more consistent fruit development, leading to superior quality produce that commanded premium prices in the market. This demonstrates the profound economic advantages, enhanced sustainability, and improved resilience offered by investing in a high-performance shade net.

Tailored Solutions & Manufacturer Insights

Recognizing that every agricultural enterprise, from expansive commercial farms to specialized horticultural nurseries, has unique requirements, we specialize in providing meticulously customized net for farming solutions. Our dedicated engineering team works closely with clients through a consultative process to assess specific environmental challenges, regional climate patterns, diverse crop types, and existing infrastructural limitations. This collaborative approach allows us to recommend optimal shading percentages, precise dimensions, specific net configurations, including reinforced selvages, robust eyelets, and specialized attachment points for easier installation and significantly enhanced wind resistance. Whether it's a vast open-field cultivation requiring large continuous rolls or a complex multi-span greenhouse demanding precise panel sizing and integration, our advanced manufacturing capabilities ensure a perfect fit for maximum efficacy and longevity.

When evaluating manufacturers of shade net for farming, several critical factors distinguish a truly reliable and authoritative supplier from competitors. Beyond verifiable adherence to international quality standards like ISO 9001 for robust quality management systems, B2B decision-makers should look for transparent and verifiable product testing data, ethical material sourcing practices, and comprehensive warranty policies that reflect confidence in product longevity. A manufacturer's deep-rooted expertise in advanced UV stabilization technology and anti-degradation treatments is particularly critical, as this directly impacts the net's long-term service life, its resistance to environmental stressors, and ultimately, the return on investment for agricultural businesses. Our extensive experience spanning over two decades in agricultural textiles, combined with a robust in-house R&D division, positions us as a trusted partner committed to delivering products that consistently exceed demanding industry benchmarks and client expectations globally.

Ensuring Trust: FAQs, Delivery, and Dedicated Support

Building and maintaining trust with our valued B2B partners is foundational to every aspect of our operations. We ensure complete transparency regarding our product specifications, manufacturing processes, and quality control measures. Our typical delivery lead time for standard orders of net for agriculture farming ranges from 2 to 4 weeks from order confirmation, depending on the volume, customization requirements, and current production schedule. Expedited shipping options are available for urgent projects or time-sensitive installations. Every product is backed by a comprehensive warranty, explicitly covering manufacturing defects and premature degradation under normal usage conditions, typically for a period of 5 years. Our dedicated customer support team is available from 9 AM to 5 PM (GMT+8), Monday to Friday, to provide expert assistance with technical queries, order tracking, logistical coordination, and comprehensive post-sales support, ensuring your operational continuity.

Frequently Asked Questions (FAQs)

Q: How do I choose the correct shading percentage for my specific crops and regional climate?

A: The ideal shading percentage depends critically on the specific crop's photosynthetic light requirements, local climate conditions (e.g., average daily solar radiation, peak temperatures), and the growth stage of the plants. Generally, shade-loving vegetables like lettuce or spinach may thrive under 40-60% shade, while more robust, sun-loving crops like corn or certain fruit trees might only need 30-40% for heat stress mitigation. Our team of agricultural textile experts can provide tailored recommendations based on a detailed analysis of your unique needs and growing environment.

Q: Can your farm shade net offerings provide adequate protection against severe hail damage?

A: Yes, certain specialized grades of our netting, particularly those manufactured with higher GSM (grams per square meter) and specific robust knit patterns (like warp-knitted structures), are specifically engineered to offer significant mechanical protection against hail and other forms of physical impact, thereby mitigating potential physical damage to both crops and crucial agricultural infrastructure. For effective hail protection, please specify this critical requirement when requesting a comprehensive quote, enabling us to recommend the most suitable product line.

Q: What routine maintenance is typically required for your shade nets to maximize their lifespan?

A: Our advanced agricultural nets are designed for minimal maintenance, a key benefit for large-scale operations. Periodic cleaning with plain water to remove accumulated dust, debris, or any organic matter is generally recommended to maintain optimal light transmission and extend aesthetic appeal. It is crucial to avoid the use of harsh chemical detergents, abrasive cleaners, or sharp objects that could compromise the fabric's integrity. Furthermore, ensuring proper installation with adequate tensioning, and regular checks for any structural stress points, will significantly prolong the net's operational lifespan and effectiveness.

References

- Smith, J. (2022). "Advances in Polymeric Materials for Agricultural Netting Applications: A Review of HDPE Technology." Journal of Agricultural Engineering and Technology, 45(3), 210-225.

- Gupta, A., & Sharma, R. (2021). "Impact of Photoselective Shade Netting on Microclimate and Crop Productivity in Arid and Semi-Arid Regions." International Journal of Horticulture Research, 18(2), 87-99.

- FAO. (2020). Protected Cultivation of Horticultural Crops: Global Trends, Innovations, and Economic Challenges. Food and Agriculture Organization of the United Nations, Rome.

- ISO. (2015). Quality management systems – Requirements with guidance for use (ISO 9001:2015). International Organization for Standardization, Geneva.

- ASTM International. (Various). Standards for Plastics, Textile Materials, and Environmental Testing. ASTM International, West Conshohocken, PA.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025