-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

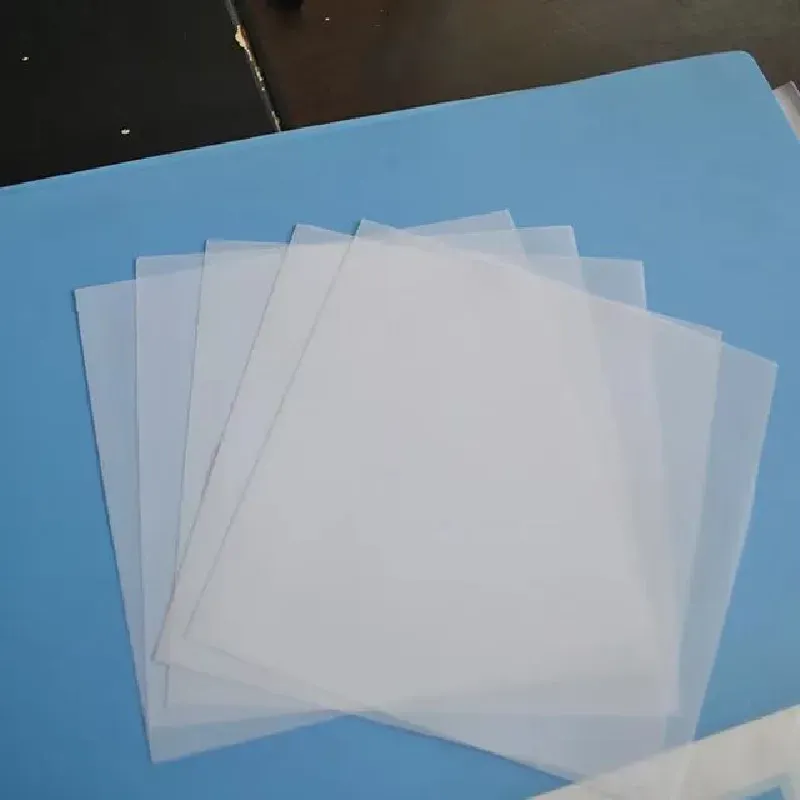

Food-Grade Nylon Screen: An Optimal Solution with Equal Emphasis on Safety and Performance

Food-grade nylon screen refers to a mesh filter product made of food-grade nylon mesh material. The core requirement of food-grade nylon mesh materials is that they will not release harmful substances when in direct contact with food, and meet food safety standards, such as the requirements of FDA and relevant regulations of the European Union.

The production process of food-grade nylon screen needs strict quality control, from raw material selection to processing technology to finished product detection, it must meet the high standards of food contact materials to ensure its safety and reliability in use.

Material Characteristics of Food-Grade Nylon Screen

As a synthetic polymer material, nylon is widely used in industry and daily life for its superior performance. Food grade nylon mesh screen has the following unique advantages in material:

- High strength and durability

Nylon fiber has high strength and good toughness. Even in high-strength filtration environment, food-grade nylon netting can still maintain good shape and structural integrity, and it is not easy to be damaged after long-term use.

- Excellent heat resistance

Food-grade nylon screen has good heat resistance and can maintain stability at high temperature. This makes it outstanding in food industry, such as high-temperature cooking, baking and other applications.

- Chemical resistance

Nylon has tolerance to many chemicals, including weak acids, weak bases and organic solvents, so it is suitable for all kinds of liquid filtration scenes, such as juice, milk, soy sauce and other food processing links.

- Non-toxic and harmless, safe and environmentally friendly

Food-grade nylon mesh materials have passed authoritative testing to ensure that no harmful substances are released. Its environmental protection characteristics also make it meet the needs of modern sustainable development.

- Precision aperture and air permeability

Nylon screen can produce products with different pore sizes, ranging from micron level to millimeter level, with high filtration efficiency and good air permeability, which can meet the requirements of fine filtration.

Advantage Analysis of Food-Grade Nylon Screen

Compared with other materials (such as metal mesh, stainless steel screen or other plastic materials), food-grade nylon mesh screen has several unique advantages:

- Higher security

Food-grade nylon mesh is designed for direct contact with food, which fully meets food safety standards and will not pose a threat to human health.

- Lightweight and flexible

Compared with metal materials, nylon screen is lighter in weight, more flexible and easy to process and operate.

- Cost economy

Although food-grade nylon screen has superior performance, its production cost is relatively low and its cost performance is high.

- Strong customization

The aperture size and shape of nylon screen can be customized according to specific application requirements to adapt to different scenes.

Future Development Trend of Food-Grade Nylon Screen

With the improvement of food safety and environmental protection requirements, the market demand for food-grade nylon mesh will continue to grow. In the future, its development trend is mainly reflected in the following aspects:

- Intelligence and automation

Food processing equipment is developing in the direction of intelligence. As an important part of it, nylon screen will be integrated with intelligent equipment to improve filtration efficiency and accuracy.

- Research and development of new materials

In the future, food-grade nylon screen may introduce more high-performance materials, such as improving nylon material through nanotechnology to further improve its filtration accuracy and durability.

- Sustainable development

The enhancement of environmental awareness has prompted production enterprises to pay more attention to sustainable development. The production of food-grade nylon screen will develop in a more environmentally friendly direction, such as using recyclable materials or reducing carbon emissions during production.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025