-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

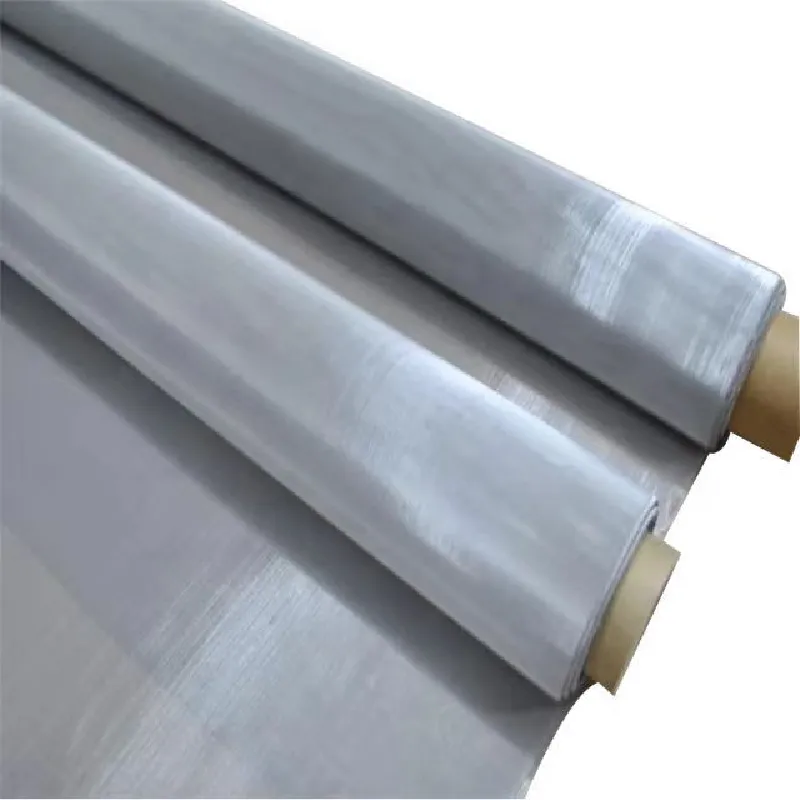

galvanized steel wire mesh

Galvanized Steel Wire Mesh An Overview

Galvanized steel wire mesh is a versatile and durable product widely used across various industries due to its unique properties and benefits. Made from high-quality steel wire that has been coated with a layer of zinc, galvanized steel wire mesh offers increased resistance to rust and corrosion, making it ideal for outdoor and industrial applications.

Composition and Manufacturing Process

The manufacturing process of galvanized steel wire mesh begins with the production of steel wire. The steel is drawn into fine wires through a series of dies that shape and size the wire according to the desired specifications. This wire is then subjected to galvanization, a process where it is coated with a layer of zinc to protect it from environmental elements. The galvanization can be achieved through two principal methods hot-dip galvanization or electro-galvanization.

In hot-dip galvanization, the steel wire is immersed in molten zinc, creating a thick and robust zinc coating. This method provides a longer-lasting finish and better protection against corrosion. On the other hand, electro-galvanization involves applying a thinner layer of zinc through an electrochemical process. While this offers some level of protection, it may not be as durable as hot-dipped counterparts.

Once the wires are galvanized, they are woven together into mesh sheets or rolls, resulting in a final product that combines strength, flexibility, and resilience.

Applications of Galvanized Steel Wire Mesh

Galvanized steel wire mesh is utilized in a myriad of applications, thanks to its robust features

. Here are some common uses1. Construction and Building In construction, galvanized wire mesh is often used for reinforcing concrete, providing additional strength for floors, walls, and ceilings. It's also used as a form of protection for scaffolding and construction sites.

2. Fencing The durability and resistance to rust make galvanized wire mesh a popular choice for fencing. It is commonly used in garden fences, zoo enclosures, and agricultural fencing, providing security and visibility without compromising aesthetics.

galvanized steel wire mesh

3. Industrial Applications In various industries, galvanized wire mesh is utilized in the manufacturing of filters, sieves, and screens. Its strength and durability make it suitable for applications that require high filtration efficiency.

4. Agriculture In the agricultural sector, galvanized wire mesh is used for cages, livestock partitions, and bird aviaries. Its resilience against weather elements ensures the safety and containment of animals.

5. Architectural Features Galvanized wire mesh can also be employed in architectural designs, providing elegant solutions for balustrades, partitions, and exterior facades. Its modern aesthetic appeals to contemporary design trends.

Advantages of Galvanized Steel Wire Mesh

One of the primary advantages of galvanized steel wire mesh is its resistance to corrosion and rust. The zinc coating acts as a barrier against moisture, ensuring longevity even in harsh environments. This durability translates into lower maintenance costs and a longer lifespan compared to non-galvanized alternatives.

Additionally, galvanized steel wire mesh offers excellent structural integrity; it withstands substantial weight and pressure, making it suitable for various demanding applications. Its flexibility allows for easy installation and manipulation, accommodating specific project requirements.

Environmental Considerations

Galvanized steel is also considered an environmentally friendly option. The zinc used in the galvanization process is recyclable, and the process itself reduces the need for frequent replacements due to deterioration. When the mesh reaches the end of its lifecycle, it can be recycled, contributing to a more sustainable construction practice.

Conclusion

In conclusion, galvanized steel wire mesh is an essential product in modern construction and industrial applications. Its combination of strength, corrosion resistance, and versatility makes it an ideal choice for various projects across multiple sectors. As industries continue to evolve, the demand for high-quality materials like galvanized steel wire mesh will undoubtedly remain robust, reflecting its integral role in promoting durable and sustainable practices. Whether used in construction, fencing, filtration, or architectural design, galvanized steel wire mesh stands out as a reliable solution, expertly balancing function and form.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025